Glass fiber reinforced fire retardation styrene-acrylonitrile material and preparation method thereof

A technology of styrene and acrylonitrile, which is applied in the field of glass fiber reinforced flame retardant materials, can solve the problems of inconspicuous effect and flammability that cannot reach V-0 or 5V level, and achieve environmental friendliness, excellent strength and rigidity, The effect of high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

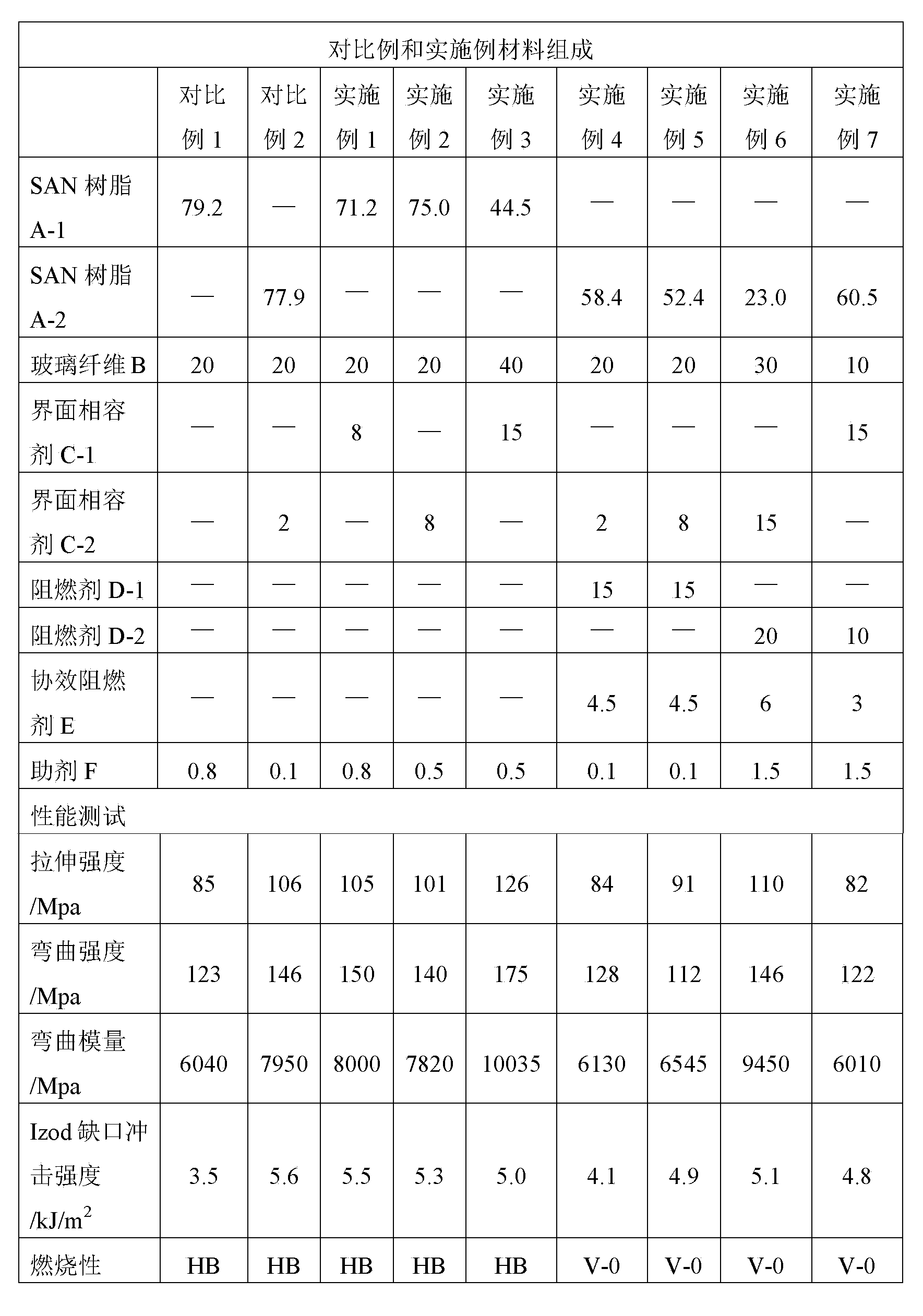

[0021] The present invention will be further described in detail below in conjunction with specific examples, but the present invention is not limited to the following examples.

[0022] A: SAN copolymer used in the examples and comparative examples; B: glass fiber; C: interfacial compatibilizer; D: flame retardant; E: synergistic flame retardant;

[0023] (1) The material composition in Table 1 is as follows:

[0024] A: SAN copolymer

[0025] A-1: The SAN copolymer used has a weight average molecular weight of 12w, wherein the acrylonitrile content is 24wt.%, produced by Taiwan Chemical Fiber Co., Ltd.;

[0026] A-2: The SAN copolymer used is a SAN resin with a weight average molecular weight of 15w and an acrylonitrile content of 30.wt%, produced by Taiwan Chimei Industrial Co., Ltd.;

[0027] B: glass fiber

[0028] The glass fiber used has a diameter of 13 μm and a chopped length of 4 mm, produced by Zhejiang Jushi Co., Ltd.;

[0029] C: interface compatibilizer

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com