Erasable environment-friendly white board ink and preparation method thereof

A whiteboard and ink technology, applied in inks, household utensils, applications, etc., can solve problems such as irritating smell, unsmooth writing, and handwriting becoming lighter and shallower, and achieve edge irritating smell, fine and smooth writing, without distinction Layer and Precipitation Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

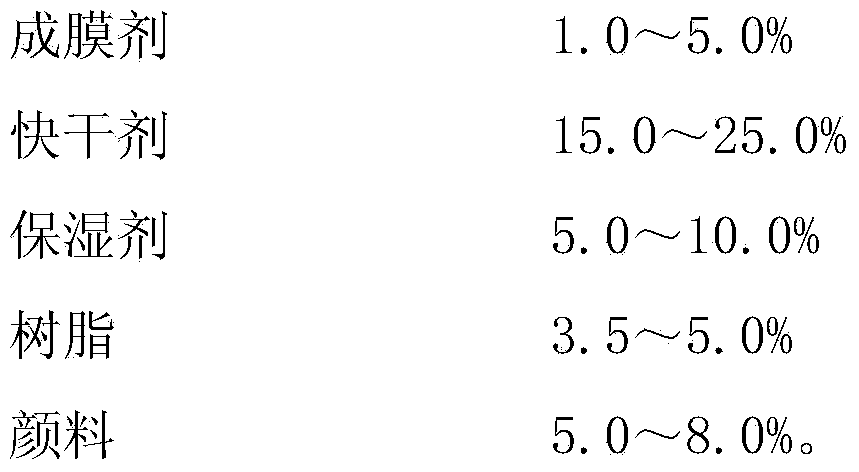

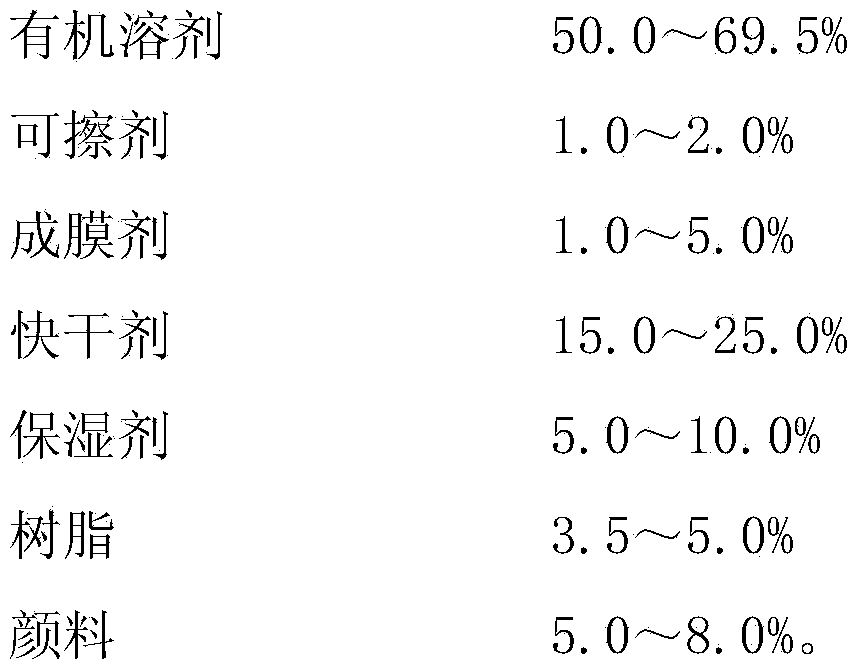

Method used

Image

Examples

Embodiment 1

[0025] The erasable environment-friendly whiteboard ink provided by the invention includes the following components and weight content, and the weight content is based on the total weight of the composition. Pigment: carbon black 8.0%, film-forming agent: polyvinyl butyral 2.0%, organic solvent: ethanol 55.0%, quick-drying agent: olein 25.0%, humectant: diethylene glycol 5.0%, resin: phenolic resin 3.5%, liniment: epoxidized triglycerides 1.5%. The preparation method is as follows: first add the solvent into the pre-dispersion pot, then add the film-forming agent, humectant, resin, and pigment in sequence under stirring until all are mixed and dispersed evenly, and finally add the liniment agent, fully stir and mix, and finally filter.

[0026] The viscosity of the prepared ink is 5-10mPa.S, the surface tension is 20-30mN / m, and the drying time on paper: 3s.

[0027] It can be seen that the ink of the present invention has moderate viscosity and fast drying time and is suitab...

Embodiment 2

[0029] Pigment: phthalocyanine 5.0%, film former: polyvinyl butyral 3.0%, organic solvent: glycerin 60.0%, quick-drying agent: glyceryl stearate 20.0%, humectant: pentaerythritol 8.0%, resin: acrylic acid Resin 2.0%, Erase Agent: Epoxy Dioctyl Tetrahydrophthalate 2.0%. The preparation method is as follows: first add the solvent into the pre-dispersion pot, then add the film-forming agent, humectant, resin, and pigment in sequence under stirring until all are mixed and dispersed evenly, and finally add the liniment agent, fully stir and mix, and finally filter.

[0030] The viscosity of the prepared ink is 5-10mPa.S, the surface tension is 20-30mN / m, and the drying time on paper: 3s.

[0031] It can be seen that the ink of the present invention has moderate viscosity and fast drying time and is suitable for use as whiteboard ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com