High-pile bearing platform foundation structure

A technology of basic structure and high pile cap, which is applied in basic structure engineering, water conservancy engineering, artificial island, etc., can solve the problems of lack of cable routing, personnel work and rest space, lack of operation and maintenance, damage to infrastructure, etc., to achieve convenient transportation. The effect of maintaining work and rest, improving overall stiffness and strength, and avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

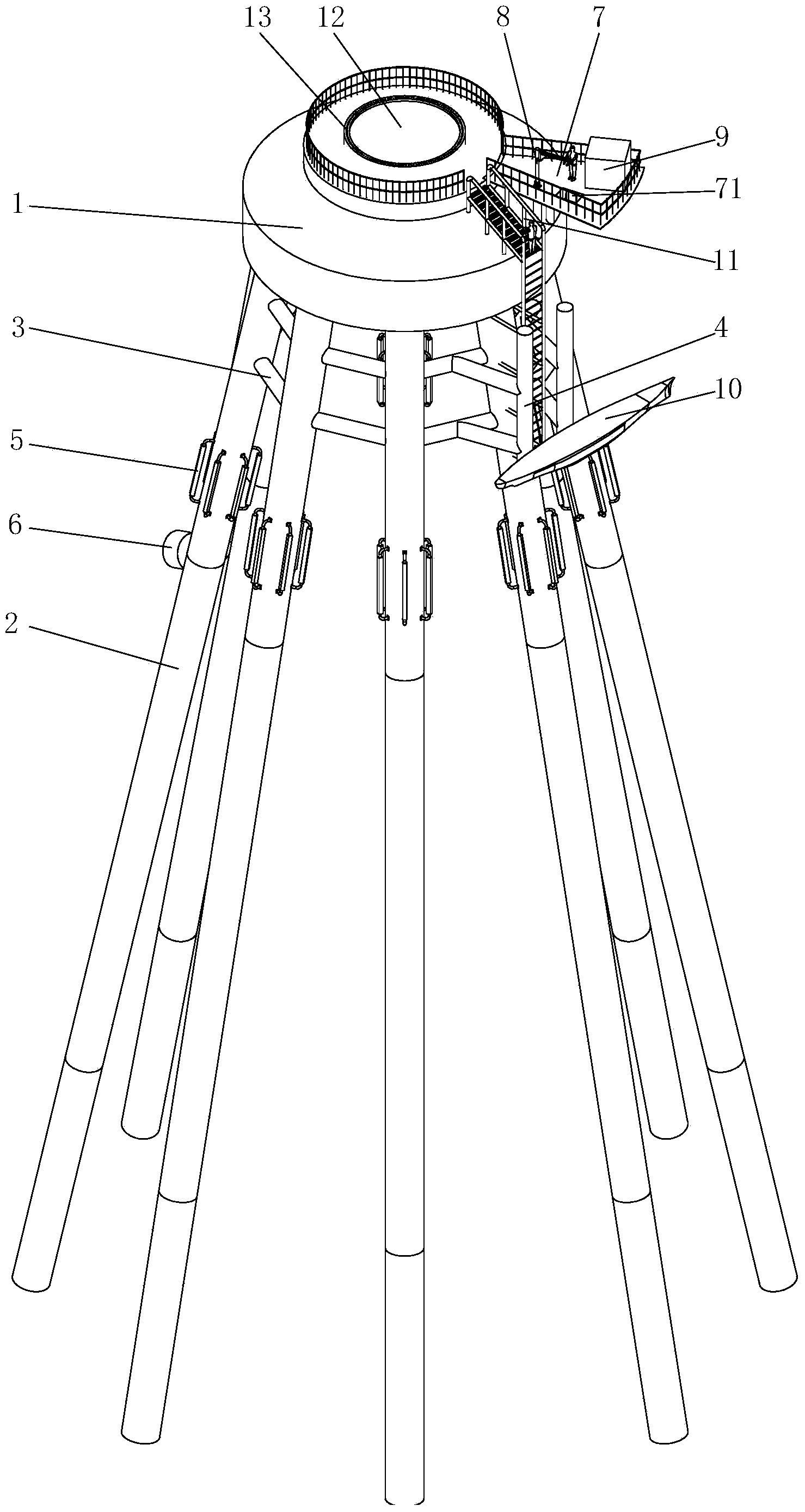

[0037] When the high pile cap foundation structure of the present invention is in use, the operation and maintenance ship 10 is docked beside the anti-collision bar 4, and the operation and maintenance personnel board the maintenance platform 12 from the ladder 11; then the operation and maintenance personnel pass the material through the material hole through the crane 8 71 is lifted from the operation and maintenance ship 10 to the platform 7 or cap 1, and the material hole 71 realizes the lifting of the equipment between the platform 7 and the operation and maintenance ship 10; when the container 9 is an electrical container, the safety distance and maintenance space between the electrical equipment are sufficient , which is convenient for the operation and maintenance personnel to operate. When the container 9 is a temporary rest container, it is convenient for the operation and maintenance personnel to rest; when the fan cable needs to be routed, the cable can pass through ...

Embodiment 2

[0039] In this embodiment, two containers 9 can be set on the platform 1, one of which is an electrical container and the other is a temporary rest container, which is convenient for installation of electrical equipment and for personnel to rest.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com