Independent pitch system and pitch method based on effective hydraulic damping

An independent pitch and hydraulic damper technology, applied in the control of wind turbines, wind power generation, wind turbines, etc., can solve the problems of no advantage of unified pitch pitch, difference in absorbed power, replacement of inner gear ring, etc., to improve wind energy Effectiveness of utilization, fatigue load reduction, stress shock reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

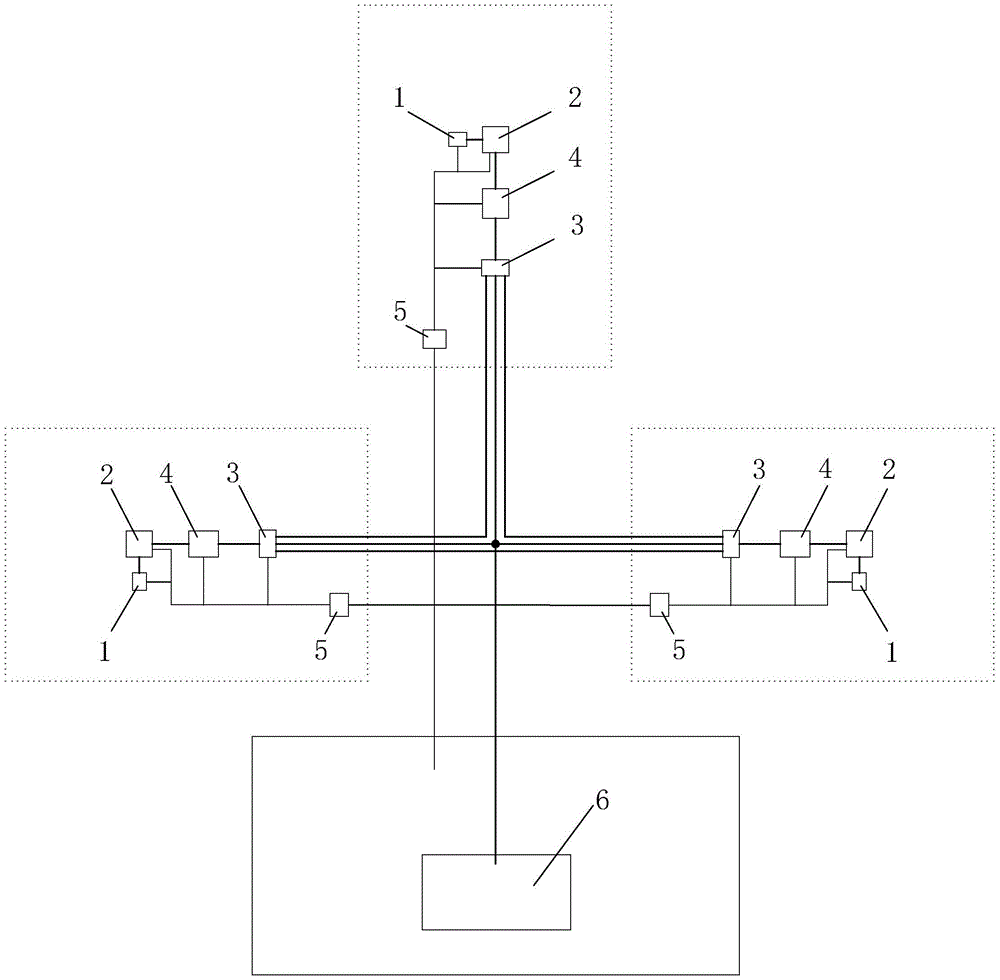

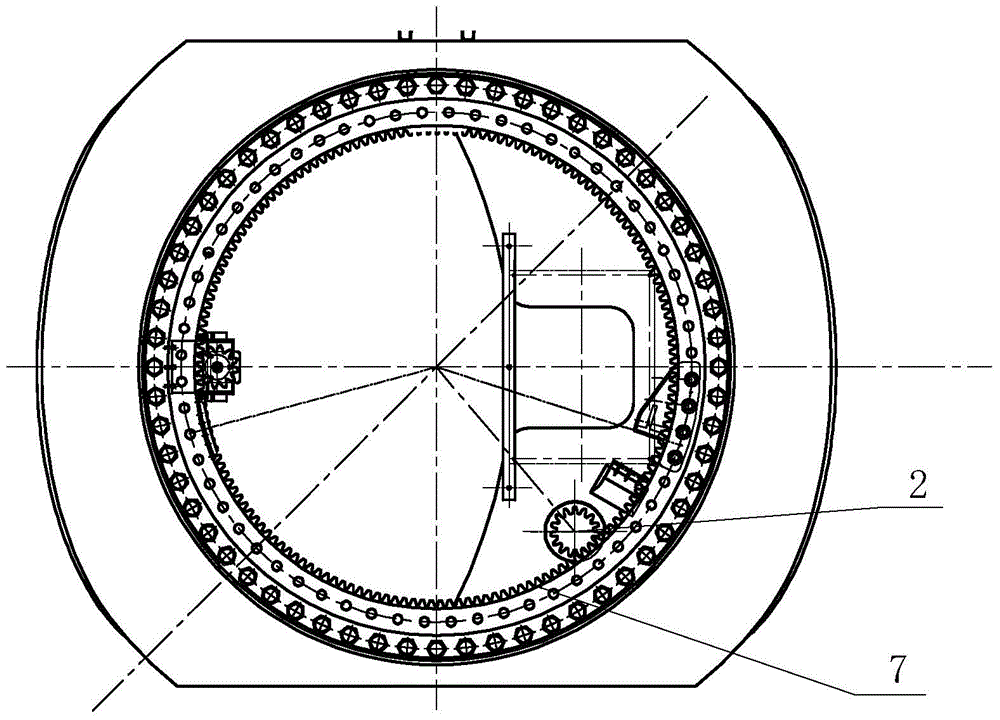

[0022] Example: such as figure 1 As shown, each blade has an independent pitch device, which includes a pitch controller 5, a pressure detection device 1, a hydraulic actuator 2 and a hydraulic damper 4, and the pinion of the hydraulic actuator 2 Located on the ring gear of the blade in the hub, the hydraulic actuator 2 is respectively connected to the hydraulic damper 4 and the pitch controller 5, and the pressure detection device 1 provided by the hydraulic actuator 2 of each blade is respectively connected to the pitch controllers of the three blades 5. The hydraulic actuator 2 of each blade is respectively connected to the hydraulic station 6 of the wind power generator through the hydraulic damper 4 and the accumulator 3 , and the hydraulic actuator 2 is respectively connected to the pitch controller 5 .

[0023] The independent backup accumulators 3 connected to the hydraulic actuators 2 of each blade are redundantly connected. When one of the backup accumulators fails, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com