Polarizer manufacturing method

A manufacturing method and polarizing plate technology, applied in chemical instruments and methods, optics, polarizing elements, etc., can solve the problems of reduced irradiance, difficulty, different measurement sensitivity, etc., and achieve the effect of good bonding strength and high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

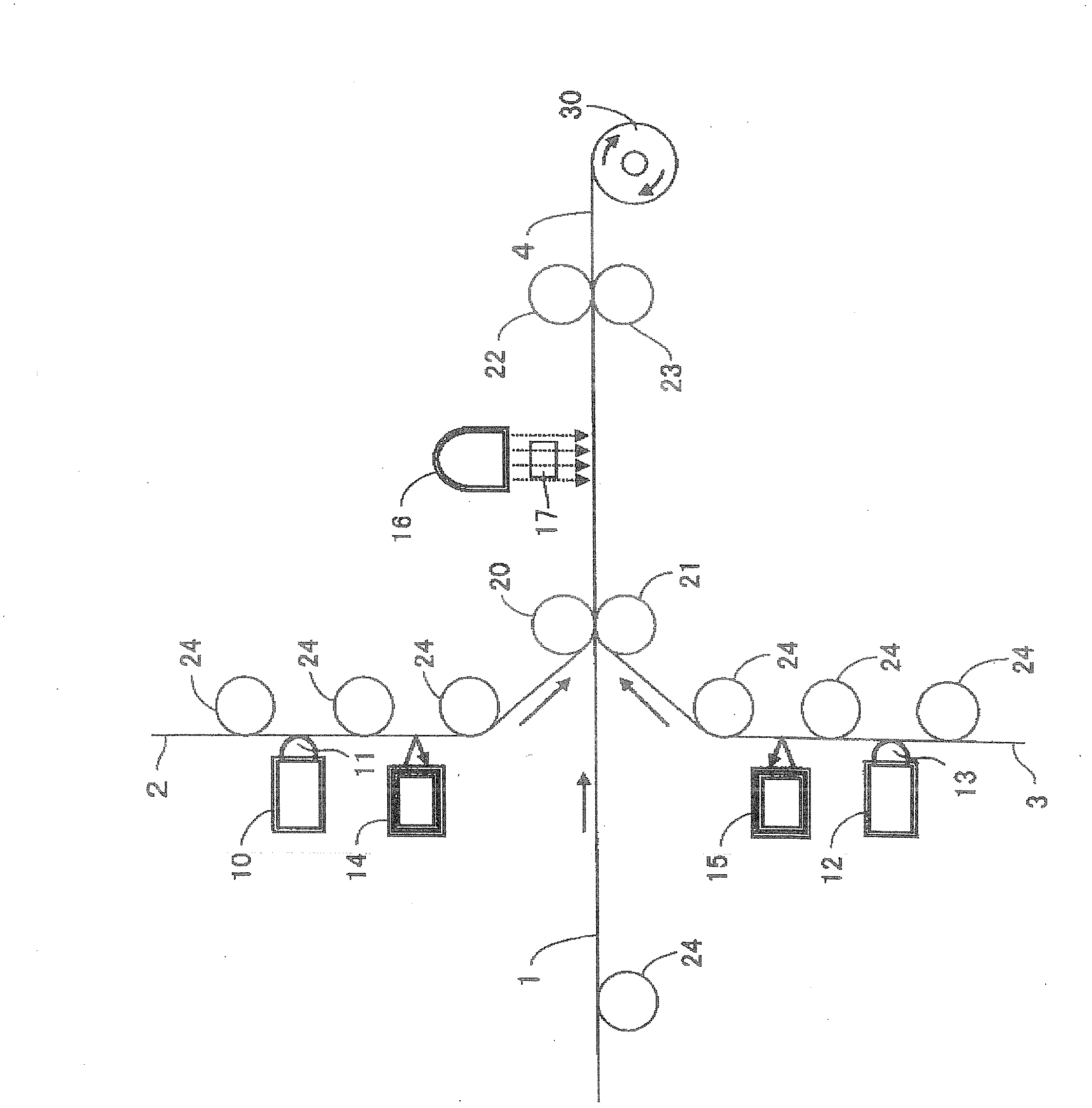

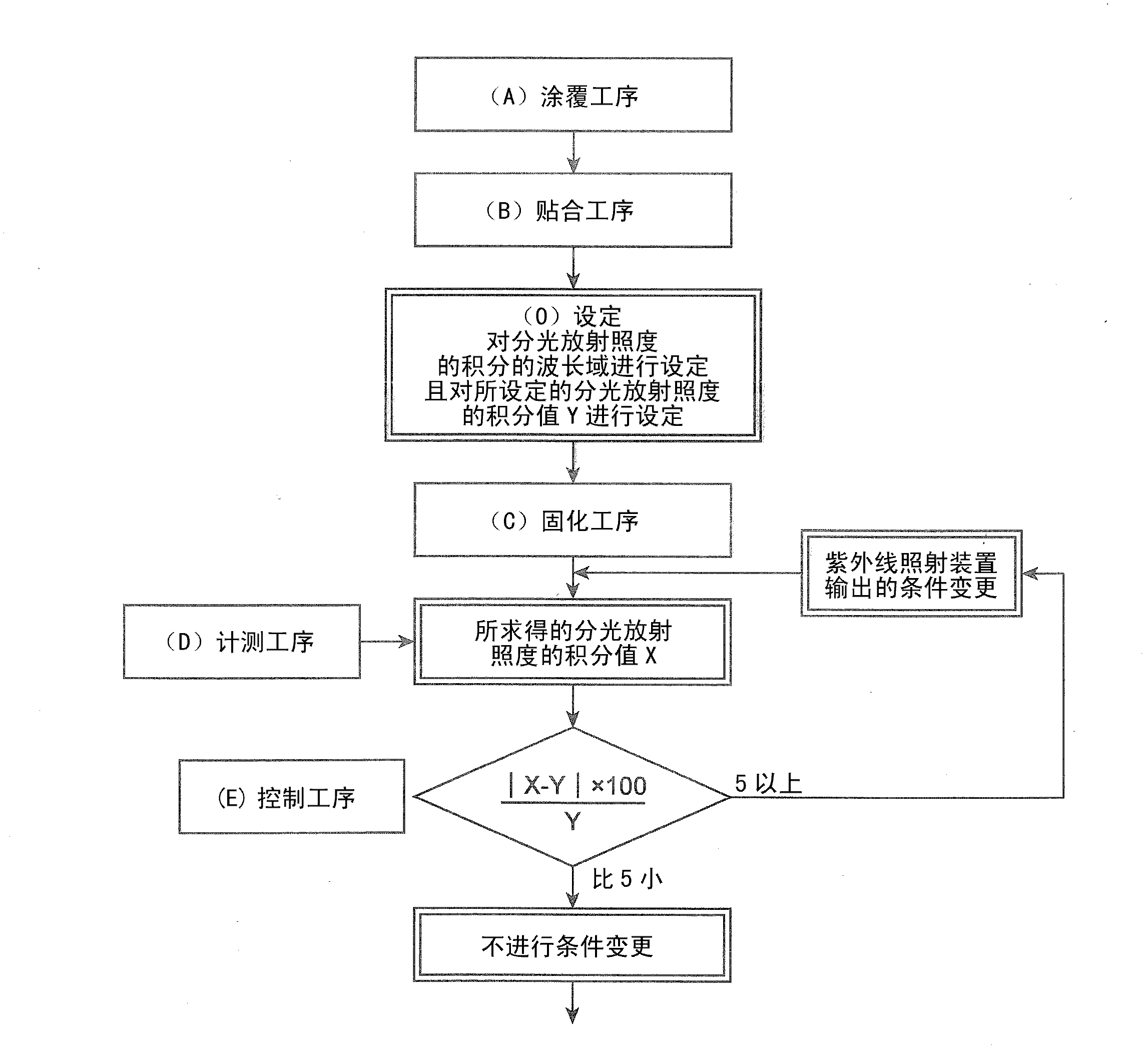

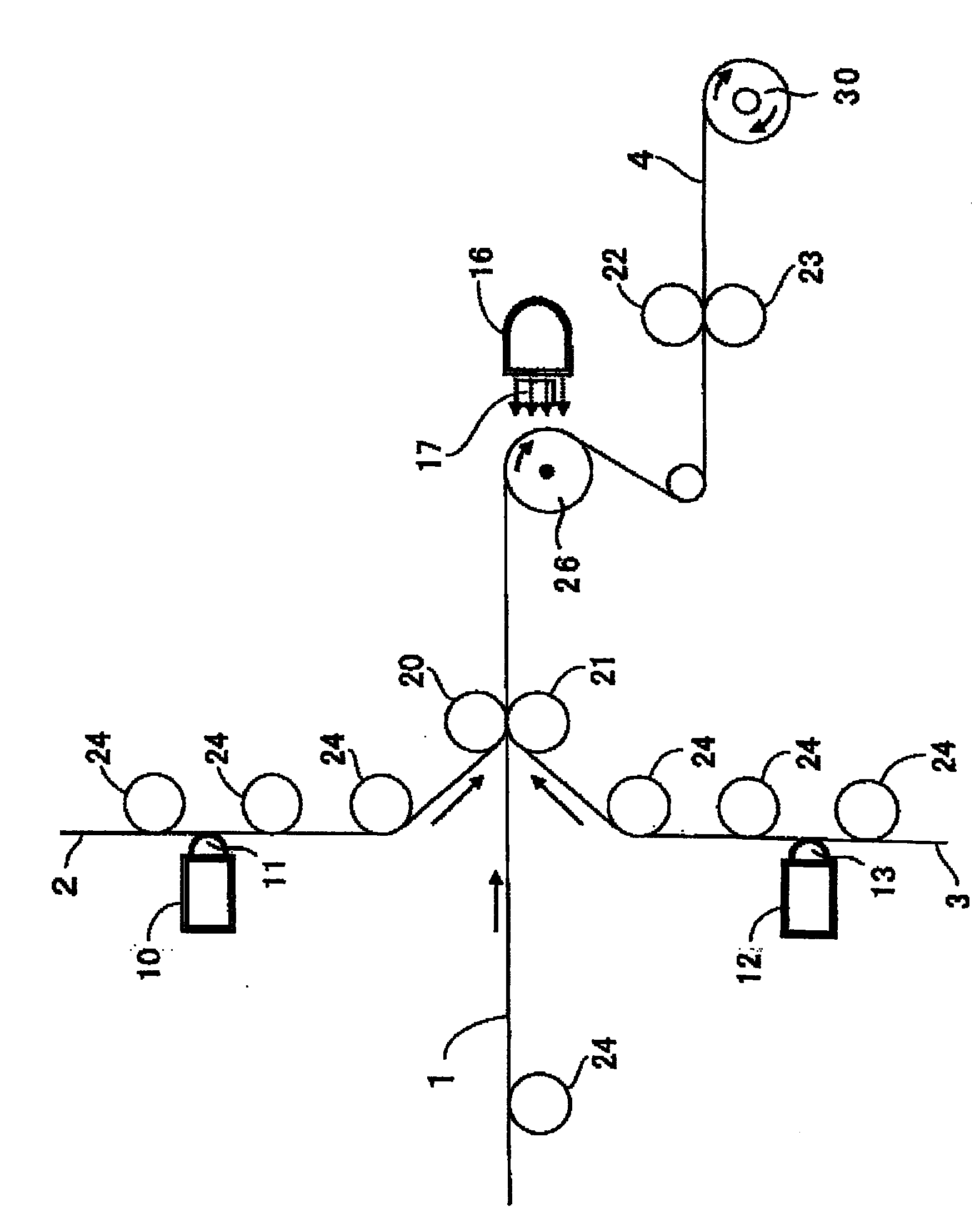

Method used

Image

Examples

Embodiment 1

[0102] (0) Materials used for experiments

[0103]In this example, as the first optical film 2, a biaxially oriented retardation film "ZEONOR" (ゼオノア) (from Japan ゼオン (ZEON) ( Co., Ltd. acquisition]. As the second optical film 3, a propylene-based resin film having a thickness of 75 μm and a width of 1490 mm and supplied from a roll was used. The above-mentioned propylene-based resin film was obtained by melting and kneading a propylene-based resin (melting point=164° C.) at an extrusion temperature of 275° C. with a single-screw extruder, extruding it into a film form with a T-die, and making it with The cooling roll set at 20° C. was brought into close contact and solidified by cooling, and then both ends were removed with a cutter. The bonding agent used for the bonding of the polarizing film 1 and the first optical film 2, and the bonding agent used for bonding the polarizing film 1 and the second optical film 3, all contain epoxy compounds and photopolymerization initiat...

Embodiment 2

[0116] A biaxially stretched polyethylene terephthalate film with a thickness of 38 μm and a width of 1330 mm was used as the first optical film 2, and a biaxially oriented retardation film made of a cycloolefin resin with a thickness of 60 μm and a width of 1330 mm was used. ZEONOR" was used as the second optical film 3, and an epoxy-based ultraviolet-curable adhesive containing an epoxy compound and a photopolymerization initiator (absorption peak wavelength=320 nm) was used as the ultraviolet-curable adhesive. Then, except for the following points, the (A) coating process, (B) bonding process, (C) curing process, (D) measurement process and control process (E) were implemented in the same manner as in Example 1 to produce polarized light. plate.

[0117] (1) In the curing step (C), the integrated value of the spectral irradiance per one lamp in the wavelength range shown in (2) below is 200mW / cm 2 (A total of 280mJ / cm total cumulative light intensity of the 2 lamps 2 ) wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com