Aligning and load reducing linear motor oil well pump

A linear motor and oil pump technology, applied in the direction of pumps, pump components, mechanical equipment, etc., can solve the problems of wearing the mating surface of the plunger and the pump barrel, increasing the pump barrel and the plunger, and large friction resistance, etc. Pump efficiency, reduced fit clearance, and small compressive load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

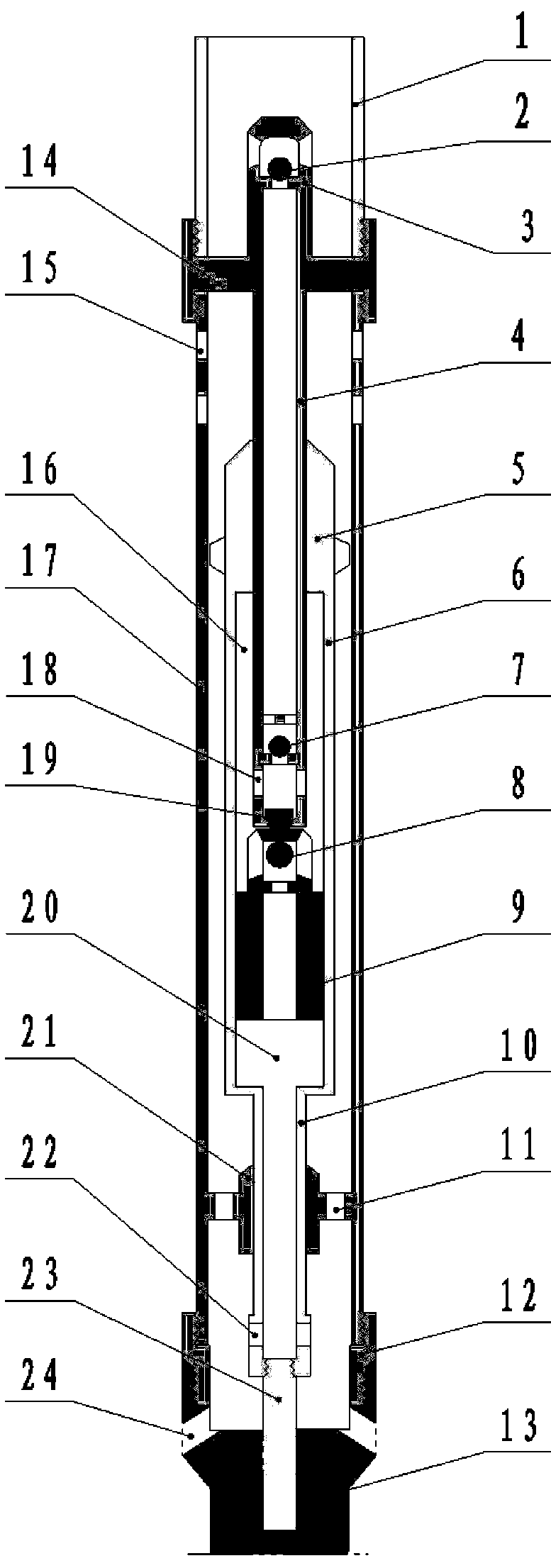

[0018] The structure of the present invention is as figure 1 Shown: a self-aligning and load-reducing linear motor oil well pump, mainly composed of a working pump barrel assembly, a working plunger assembly, an upper coupling, an upper oil outlet valve, an aligning joint, a guide plunger, an outer cylinder, and a linear motor, etc. , is characterized in that: the upper oil outlet valve 2 is connected to the upper part of the upper coupling 14, the small diameter plunger 4 is connected to the lower end of the upper coupling 14, and is located in the outer cylinder 17; the working plunger assembly consists of the small diameter plunger 4, the lower oil outlet valve 7. Self-aligning joint 19, oil inlet valve 8, and large-diameter plunger 9. The upper end of the outer cylinder 17 is connected with the upper coupling 14, and the lower part is connected with the linear motor stator 13 through the lower joint 12. The inner wall of the lower part of the outer cylinder 17 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com