Ultrasonic-based and electromagnetic ultrasonic combined dual-mode nondestructive testing method and device

An electromagnetic ultrasonic and non-destructive testing technology, which is applied in the direction of measuring devices, material analysis through electromagnetic means, instruments, etc., can solve the problems of single detection parameters and low detection sensitivity, and achieve high detection accuracy and sensitivity and fast judgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

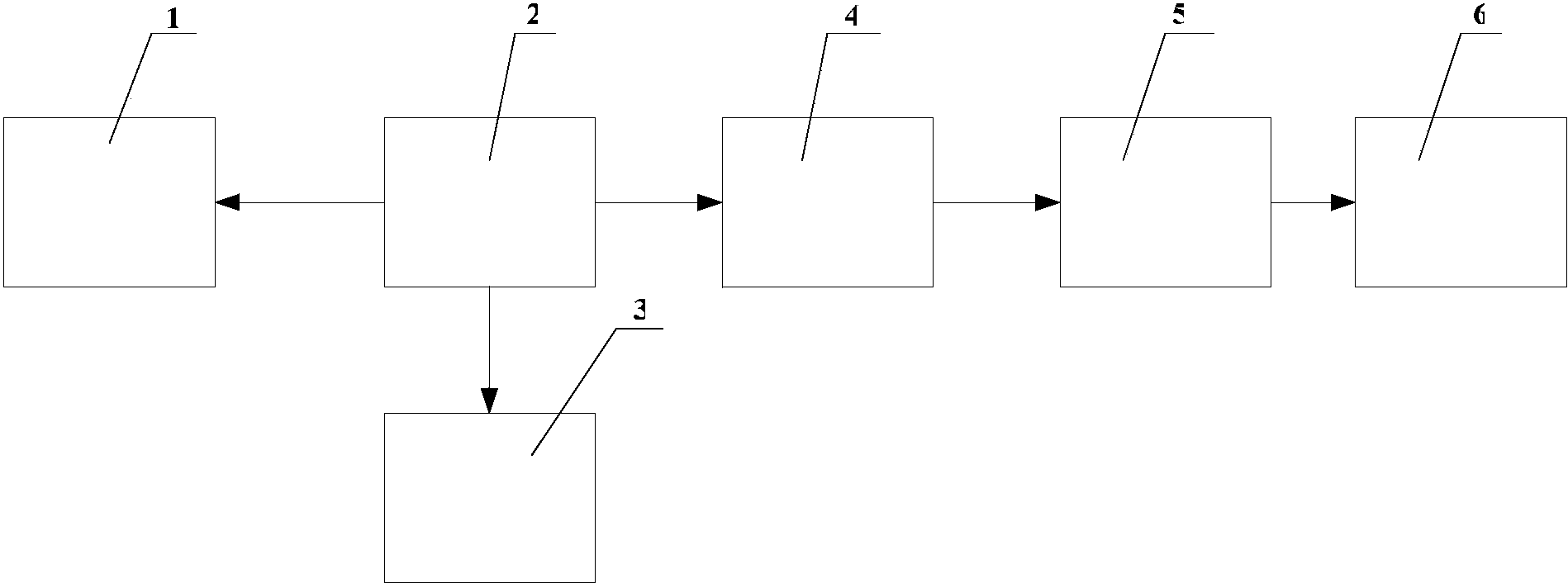

[0034] Such as figure 1 As shown, the nondestructive testing device of the present invention includes a pulse excitation system 1 , an ultrasonic probe array 4 , a magnet system 3 , a control system 2 , a signal detection processing system 5 and a reconstruction system 6 . The control system 2 is connected to the pulse excitation system 1 , the ultrasonic probe array 4 and the magnet system 3 , the ultrasonic probe array 4 is connected to the signal detection processing system 5 , and the signal detection processing system 5 is connected to the reconstruction system 6 . The detection surface of the ultrasonic probe array 4 and the metal component to be tested are coupled through water or insulating oil, and the detection surface of the ultrasonic probe array 4 is perpendicular to the direction of the main magnetic field.

[0035] The working p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com