Intelligent motor drive circuit used for controlling liquid flow

A motor drive circuit, liquid flow technology, applied in the control system, motor generator control, electrical components, etc., can solve the problems of no communication interface circuit, complex drive circuit, etc., to achieve convenient and simple system control, small size of the whole machine, The effect of less debugging effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described in detail below in conjunction with each figure:

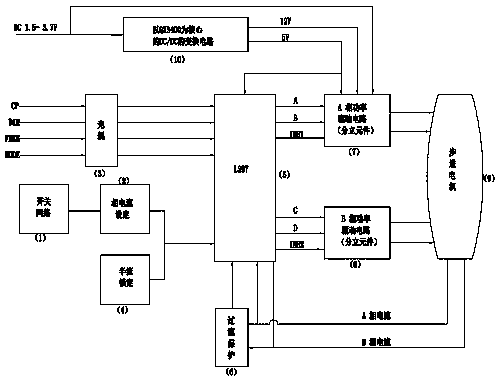

[0011] pass figure 1 As can be seen from the block diagram, the stepping motor drive system receives the stepping pulse signal CP, the direction signal DIR, the offline signal FREE and the working mode selection signal MODE, which are isolated and input to the stepping motor control circuit (5) through the optocoupler (3). , the stepping motor control circuit (5) adopts the stepping motor special control chip L297 produced by Italy SGS Semiconductor Company, the stepping motor control circuit (5) distributes according to certain rules and outputs logic control signals, and then drives through the power The circuits (7) and (8) are amplified and then applied to the input terminals of each phase of the stepping motor (9) to drive the stepping motor (9) to operate according to the command. In addition, the system is also equipped with phase current selection and setting circuit (2), swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com