Bonding wire of gold (Au) alloy

A technology of alloy bonding and bonding wire, which is applied in the direction of metal processing equipment, welding equipment, manufacturing tools, etc., can solve problems that cannot be solved, and achieve the effects of suppressing wire flow, suppressing surface deterioration, and preventing neck damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-44

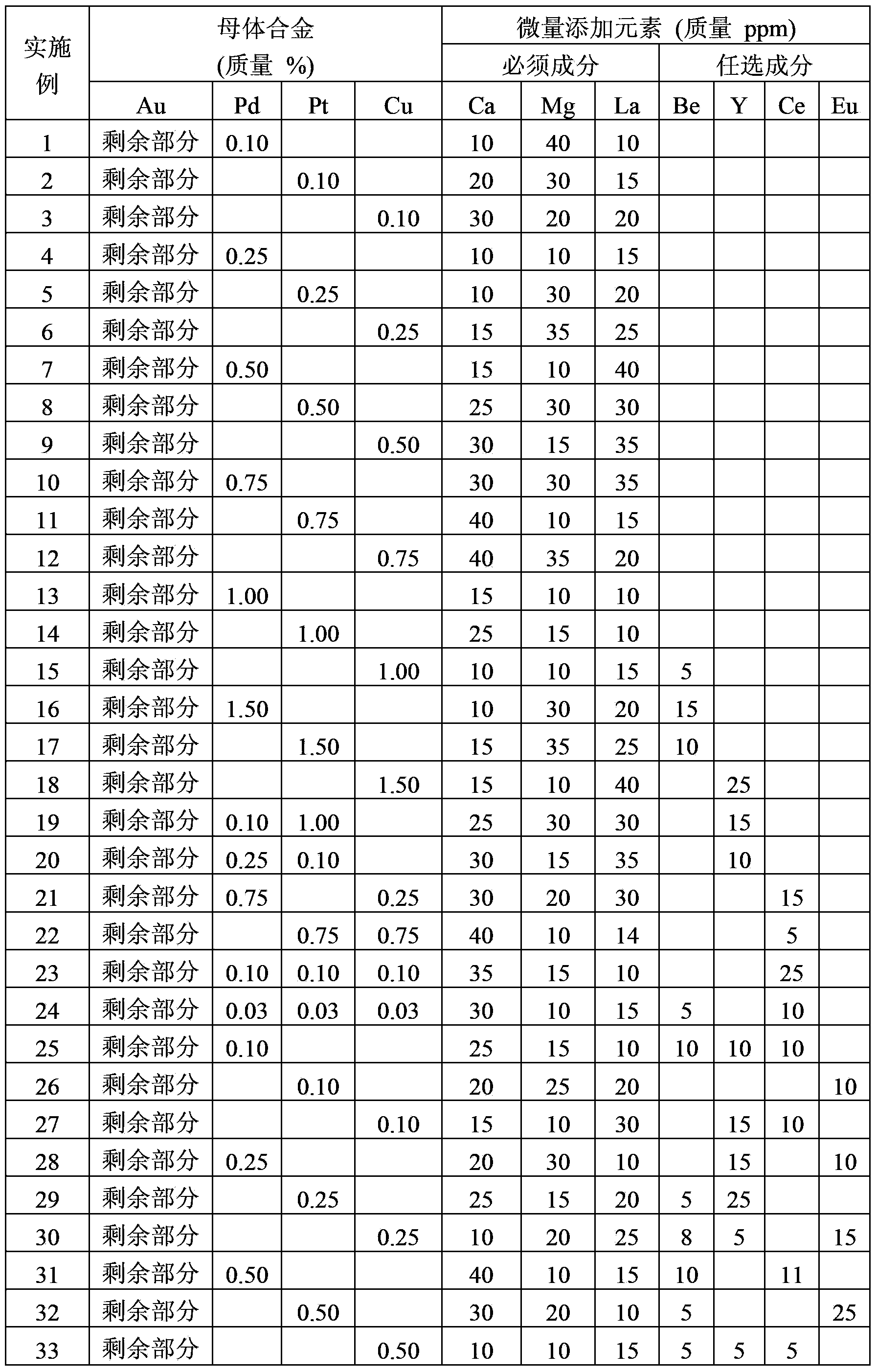

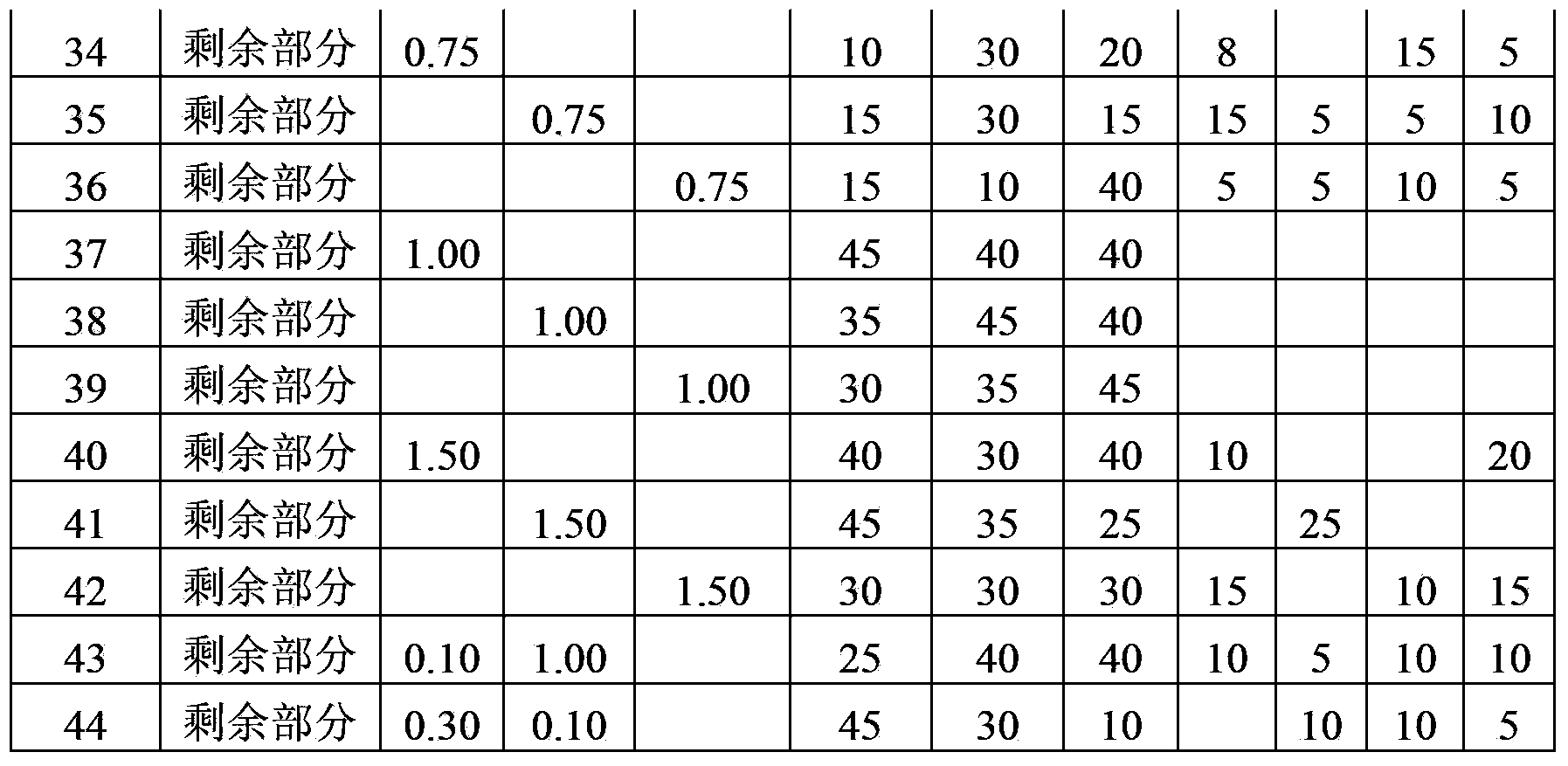

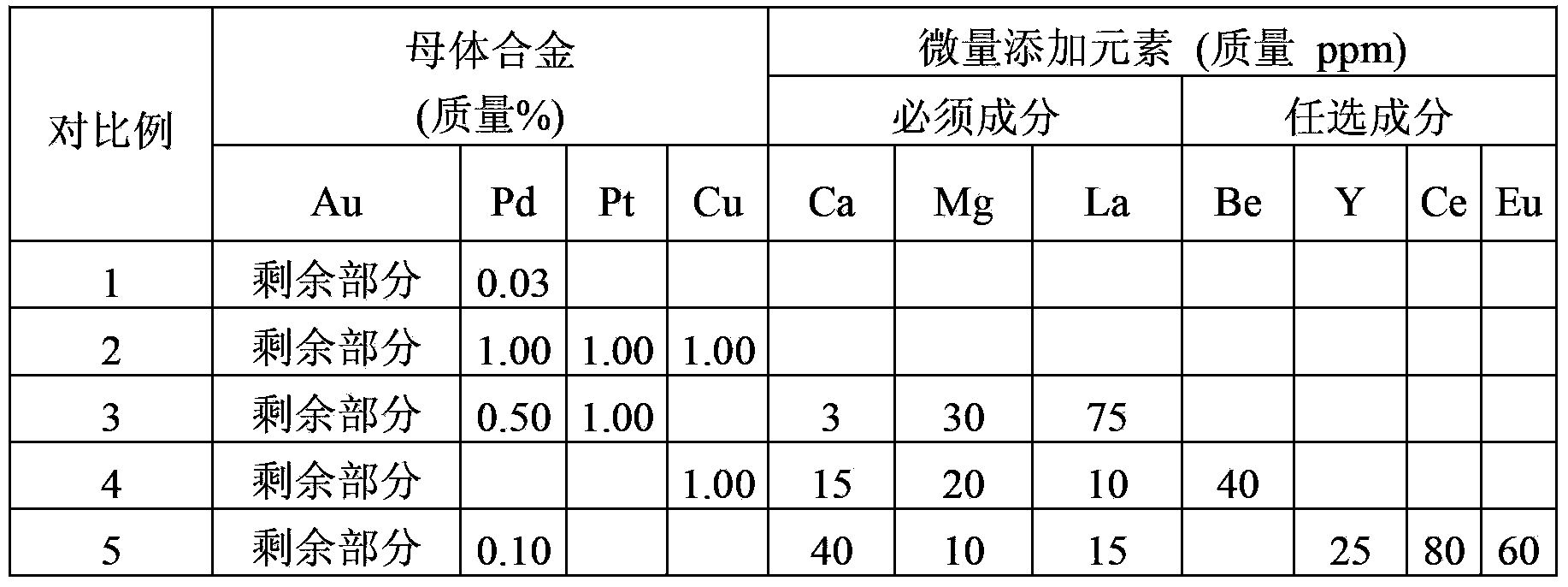

[0062] Table 1 shows the component compositions of the samples of Examples (Nos. 1-44).

[0063] A thin binary gold (Au) alloy of high-purity gold (Au) with a purity of 99.999% by mass, high-purity palladium (Pd) and platinum (Pt) with a purity of 99.999% by mass, and high-purity copper (Cu) with a purity of 99.999% by mass Among them, trace elements were formulated according to the values (ppm by mass) recorded in Table 1, and melted and casted in a vacuum melting furnace.

[0064] The above-mentioned cast alloy is continuously subjected to wire drawing processing to make wire diameters of 15 μm and 18 μm, and the elongation is adjusted to within 4% after final heat treatment.

[0065] Composition of the gold alloy wire of the embodiment of table 1

[0066]

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com