Battery separator, and method for producing same

一种电池、隔膜的技术,应用在电池用隔膜领域,能够解决不透气度升高、关闭功能降低、微孔堵塞等问题,达到不透气度升高率小、加工性低、优异耐热性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

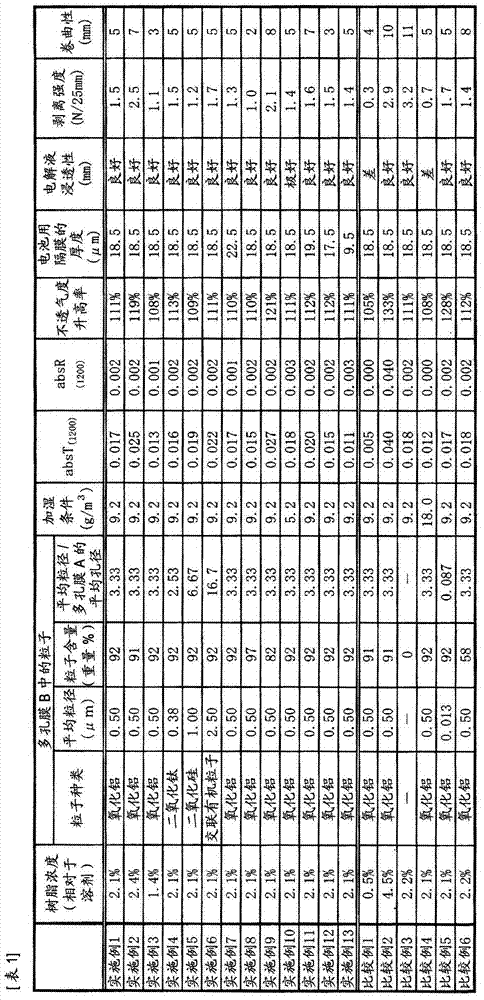

Examples

Embodiment 1

[0133] (Synthesis of fluorine-containing resin)

[0134] As the fluorine-containing resin solution, KF polymer #1120 (polyvinylidene fluoride resin solution (175° C. melting point, 12% N-methylpyrrolidone solution) manufactured by Kureha Chemical Industry Co., Ltd.) was used.

[0135] A polyvinylidene fluoride resin solution, alumina particles with an average particle size of 0.5 μm, N-methyl-2-pyrrolidone, and zirconia beads (manufactured by Toray Corporation, "Torayceram" (registered trademark) beads, 0.5 mm in diameter) were put into a polypropylene container together, and dispersed for 6 hours using a paint shaker (manufactured by Toyo Seiki Seisakusho Co., Ltd.). Next, it filtered with the filter of 5 micrometers of filtration limits, and prepared the varnish.

[0136] The concentration of fluororesin in the solution is 2.1%, and the weight ratio of fluororesin (solid content) to particles is 8:92.

[0137] Apply the above-mentioned varnish to porous membrane A (porous ...

Embodiment 2

[0139] A battery separator was obtained in the same manner as in Example 1, except that the mixing ratio of the fluororesin solution, alumina particles, and N-methyl-2-pyrrolidone used in Example 1 was 16:19:65.

[0140] The concentration of fluorine-containing resin in the solution component is 2.4%, and the weight ratio of fluorine-containing resin (solid content) to particles is 9:91.

Embodiment 3

[0142] The mixing ratio of the fluororesin solution used in Example 1, alumina particles, and N-methyl-2-pyrrolidone was 10:14:76, except that it was performed in the same manner as in Example 1 to obtain a battery separator .

[0143] The concentration of fluorine-containing resin in the solution component is 1.4%, and the weight ratio of fluorine-containing resin (solid content) to particles is 8:92.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com