Volatile organic compound recovery system and recovery process thereof

A volatile organic compound and recovery system technology, applied in the field of volatile organic compound treatment system, can solve the problems of equipment cost and fuel increase, a large amount of air pollution fees, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example 〕

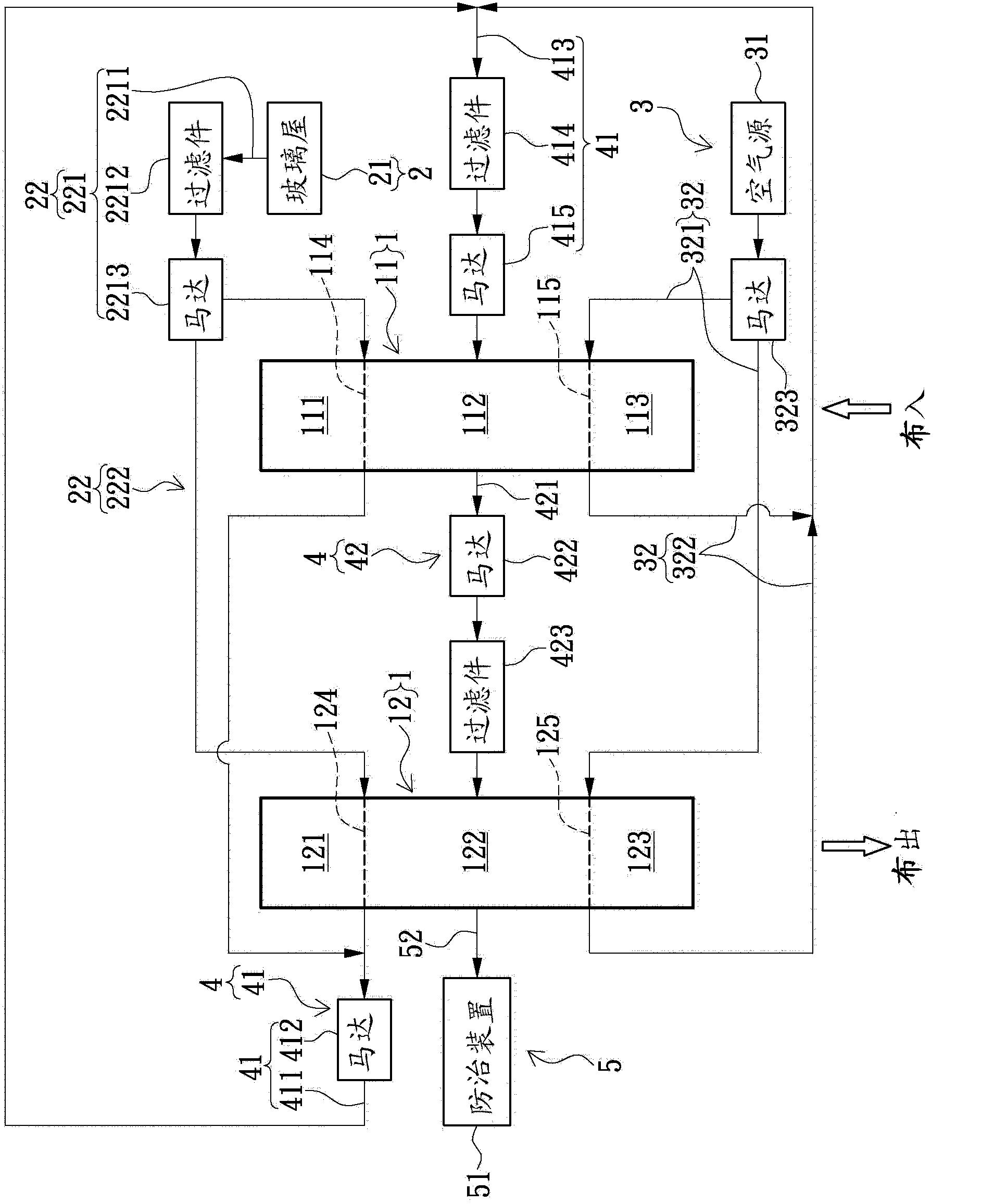

[0080] The present invention mainly provides a recovery system for volatile organic compounds, which can first introduce all gases (including VOCs) in the system into the heat treatment unit through the pipeline configuration of the system, and then discharge them into the prevention and control unit together, so as to improve the overall efficiency of the system. Equalization control efficiency. Hereinafter, specific structural features and recovery processes of the recovery system for volatile organic compounds will be described based on various drawings.

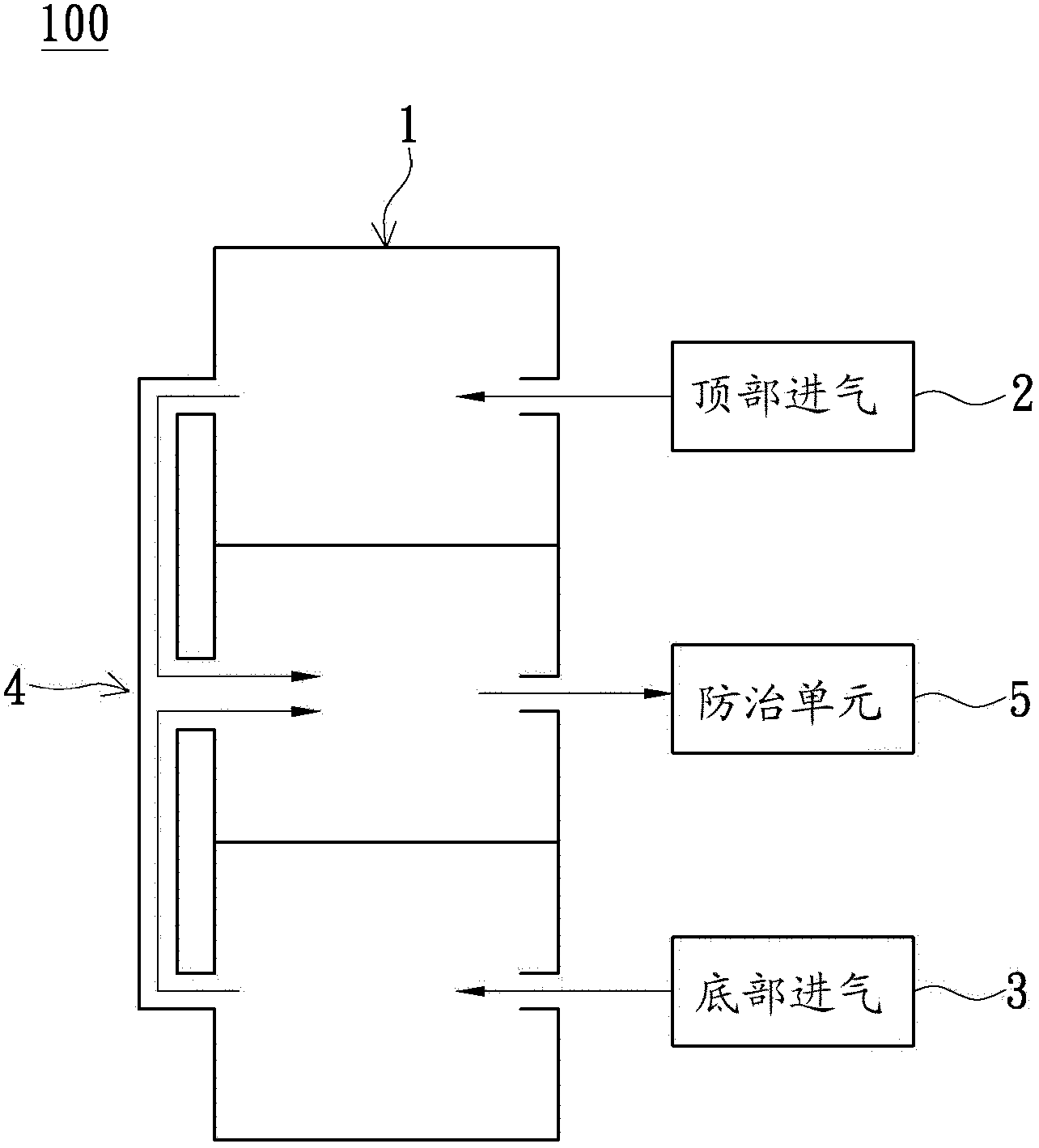

[0081] see figure 2 , is a schematic diagram of a recovery system for volatile organic compounds of the present invention, the recovery system 100 for volatile organic compounds includes a heat treatment unit 1, a top air intake unit 2, a bottom air intake unit 3, an air-inducing unit 4 and a control Unit 5. The heat treatment unit 1 includes an upper air chamber, an oven and a lower air chamber (not shown), the top ai...

no. 2 example

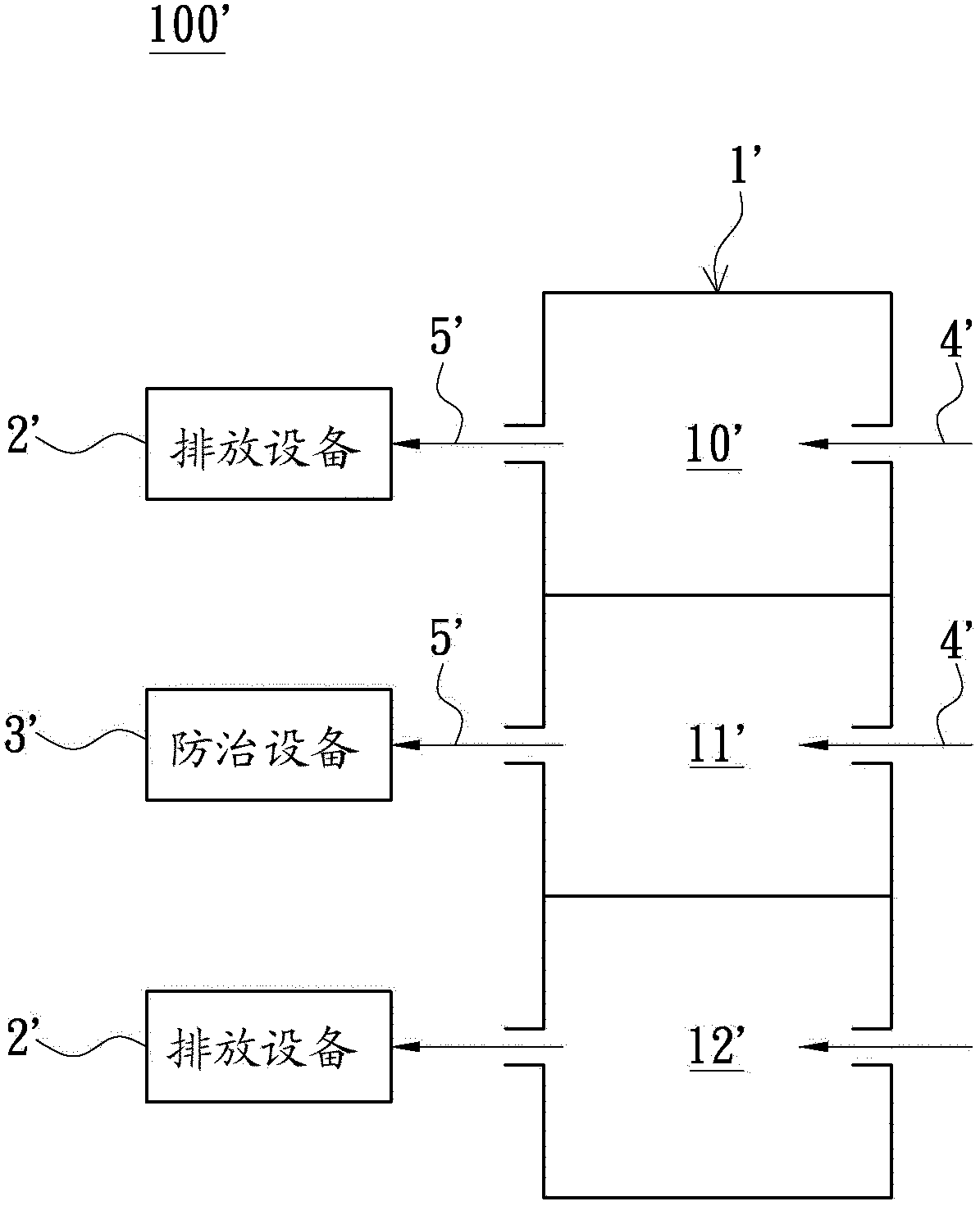

[0098] see Figure 5 , is a block diagram of a recovery system for volatile organic compounds in the second embodiment of the present invention. The difference between this embodiment and the previous embodiment is that the air outlet 322 of the air pipeline 32 of the bottom air intake unit 3 It is connected with the exhaust pipeline 52 of the control unit 5 .

no. 3 example

[0100] see Image 6 , is a block diagram of a recovery system for volatile organic compounds according to the third embodiment of the present invention. The introduction tube 2211 is connected and connected to the flow splitting portion 222 of the air guiding pipeline 22 through the first filter element 2212 and the first driving element 2213 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com