Numerically controlled single-column vertical lathe

A vertical lathe and single-column technology, which is applied in the field of CNC machine tools, can solve problems such as the inability to meet the processing requirements of high-precision products, complex structure of CNC lathes, and unstable operation, so as to achieve low noise, save time, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

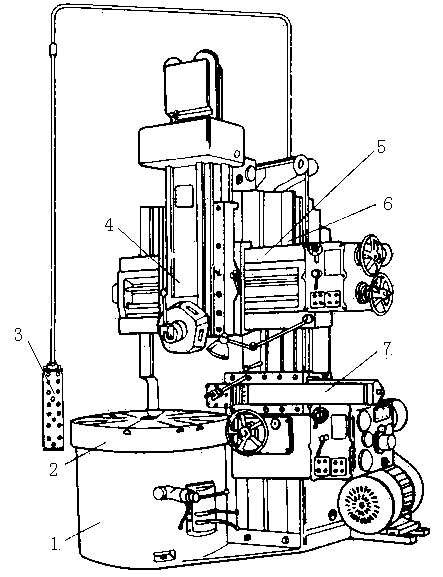

[0009] Numerical control single-column vertical lathe structure of the present invention is as figure 1 As shown, a column 6 is installed on one side of the bed 1, a beam 5 is fixedly installed on the column 6, a vertical tool rest 4 is installed on the vertical direction of the beam 5, a workbench 2 and a column 6 are installed on the bed 1 directly below the vertical tool rest 4 A rotatable operation panel 3 is installed on the upper part, and the operation panel 3 is a touch screen. The worktable 2 is driven by the static pressure guide rail installed on the bed 1 to drive the reciprocating motion. The radial direction of the main shaft adopts high-precision NN30 bearings, which have high rotation accuracy and large bearing capacity. The gear box adopts 40Cr ground gear, which has high precision and low noise; the sliding surface of the guide rail is treated with plastic to improve wear resistance; the castings of the machine tool are made of high-quality lost foam resin san...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com