Hydraulic focusing assembling method for various nano-wire arrays based on micro-fluid chip

A technology of microfluidic chips and nanowire arrays, applied in nanotechnology, microstructure devices, manufacturing microstructure devices, etc., can solve problems such as the lack of nanowire assembly methods, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention are described as follows in conjunction with the accompanying drawings:

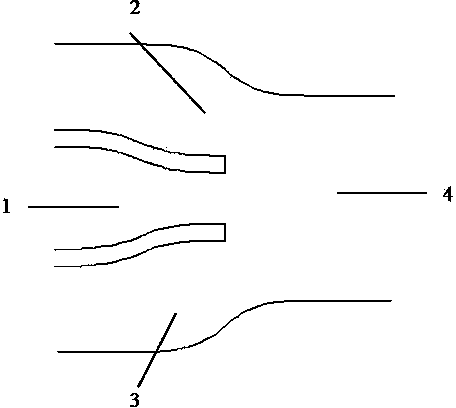

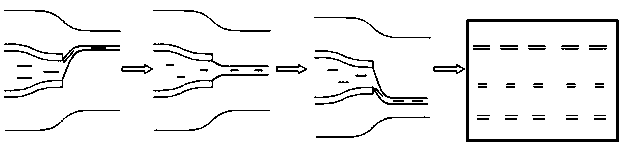

[0018] like figure 1 and figure 2 As shown, take deionized water, ethanol solution of silver nanowires and ethanol solution of gold nanowires to prepare nanowire arrays. First, the silver nanowire solution is injected into the sample inlet of the microfluidic chip as the sample flow, and at the same time, the deionized water is injected as the sheath flow, and the silver nanowire solution will be focused into a thin stream; the size and position of the focused nanowire solution The flow rate of the sheath flow and the sample flow can be adjusted so that the silver nanowire solution reaches the predetermined position with a predetermined size; after 20 minutes, the silver nanowire solution is replaced with the gold nanowire solution, and the flow rate of the sheath flow is adjusted at the same time to make the gold nanowire solution The solution arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com