Fenton-like catalyst as well as preparation method and application thereof

A catalyst, Fenton's technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of serious mass loss of oxidized carbon nanotubes and damage to carbon nanotubes Problems such as the structure of the tube body and the limited catalytic effect of the catalyst can achieve the effects of improving catalytic reaction efficiency, high catalytic activity, considerable economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

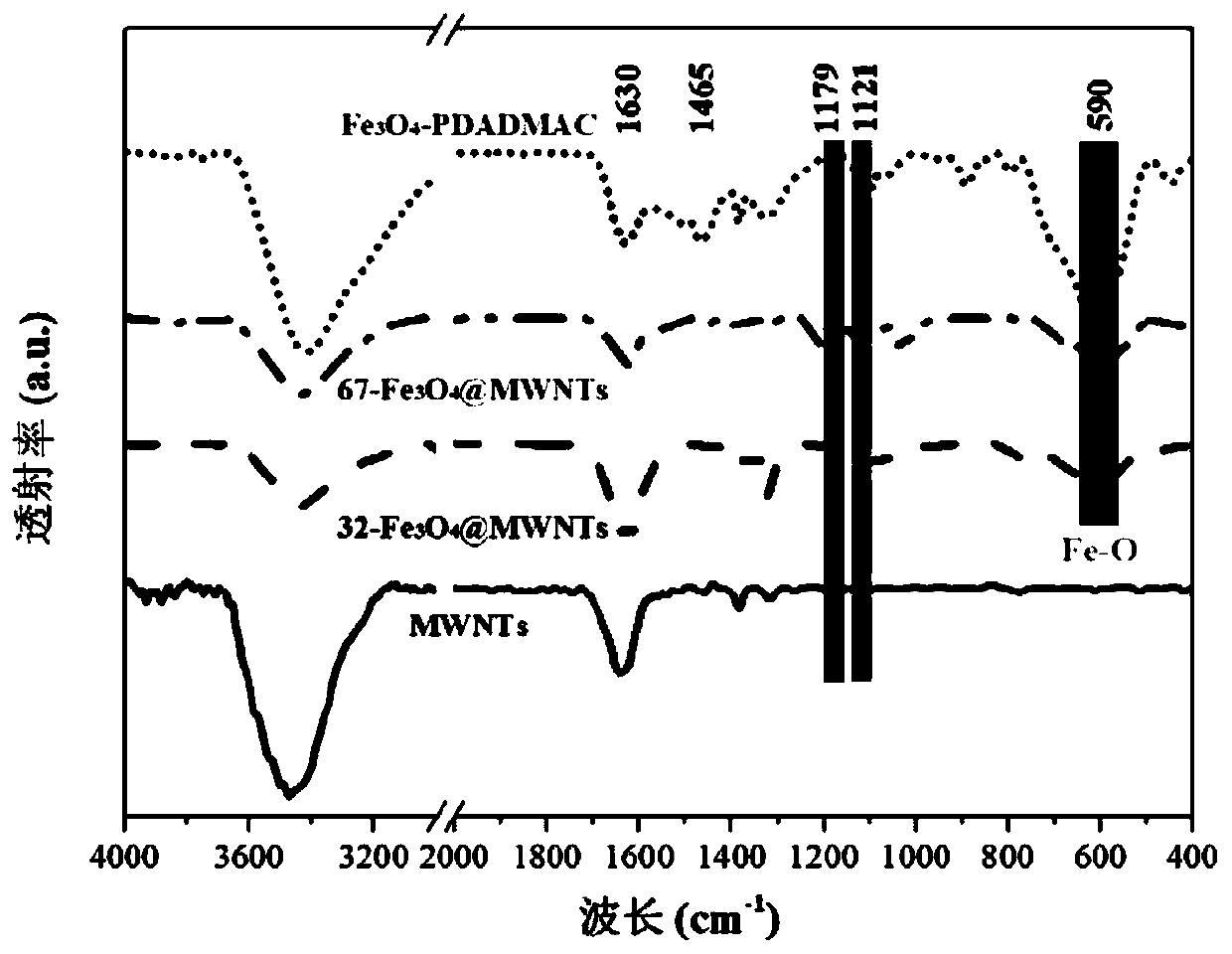

[0051] This embodiment provides a Fenton-like catalyst, which is prepared through the following steps.

[0052] Dissolve 20mmol ferric chloride hexahydrate and 10mmol ferrous sulfate heptahydrate solid in 25mL of 0.12M dilute hydrochloric acid, stir at 400rpm, slowly add dropwise to 250mL ammonia solution at room temperature (concentration: 0.7M), in a water bath At 40° C., 7.2 g of tetramethylammonium hydroxide was added to the solution, and stirring was continued at 400 rpm for 2 hours to obtain a ferric oxide dispersion.

[0053] Add 5 mL of polydimethyldiallyl ammonium chloride (PDADMAC) solution to the ferric oxide solution to prepare a concentration of 0.05 mol L -1 The surface of the positively charged Fe 3 o 4 Dispersions.

[0054] Disperse 0.5 g of MWNTs in 150 mL of polystyrene sodium sulfonate (PSS, aq: 1 wt.%) solution, ultrasonically disperse at 400 W for 45 min, and stir at 400 rpm for 12 h to obtain a MWNTs / PSS dispersion.

[0055] Take 86.4 mL of positively...

Embodiment 2

[0059] This embodiment provides a Fenton-like catalyst, which is prepared through the following steps.

[0060] Dissolve 20mmol of ferric chloride hexahydrate and 10mmol of ferrous sulfate heptahydrate in 25mL of dilute hydrochloric acid with a concentration of 0.12M, and slowly add it dropwise to 250mL of ammonia solution at room temperature (concentration: 0.7M) under vigorous stirring at 500rpm. After completion, add 5.0 g of oleylamine into the solution in a water bath at 35° C., and continue stirring at 400 rpm for 2 hours to obtain a ferric oxide dispersion.

[0061] Add 5 mL of polydimethyldiallyl ammonium chloride (PDADMAC) solution to the ferric oxide solution to prepare a concentration of 0.05 mol L -1 The surface of the positively charged Fe 3 o 4 Dispersions.

[0062] Disperse 0.5g of MWNTs in 150mL of sodium polyacrylate (PSS, aq: 1wt.%) solution, ultrasonically disperse, and stir at 150rpm-500rpm for 12h to obtain a MWNTs / PSS dispersion.

[0063] Take 21.6mL ...

Embodiment 3

[0068] This embodiment provides a Fenton-like catalyst, which is prepared through the following steps.

[0069] Dissolve 20mmol ferric chloride hexahydrate and 10mmol ferrous sulfate heptahydrate solid in 25mL of 0.12M dilute hydrochloric acid, stir at 500rpm, slowly add dropwise to 250mL ammonia solution at room temperature (concentration: 0.7M), in a water bath At 45° C., 7.2 g of tetramethylammonium hydroxide was added to the solution, and stirring was continued at 400 rpm for 2 hours to obtain a ferric oxide dispersion.

[0070] Add 5 mL of polydimethyldiallyl ammonium chloride (PDADMAC) solution to the ferric oxide solution to prepare a concentration of 0.05 mol L -1 The surface of the positively charged Fe 3 o 4 Dispersions.

[0071] Disperse 0.5g of MWNTs in 150mL of sodium polystyrene sulfonate and sodium polyacrylate with a mass ratio of 1:1 (aq:1wt.%), disperse in an ultrasonic environment with a power of 300W, and stir at 350rpm for 12h to obtain MWNTs / PSS+ PAAS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com