A kind of fe-zn bimetallic crystalline catalyst and its preparation method and application

A catalyst and bimetallic technology, applied in the field of porous coordination polymers, can solve the problems of uncontrollable MOFs assembly process, unpredictable synthesis process, poor catalyst stability, etc., and achieve a wide range of substrates, good selectivity and yield. rate, mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

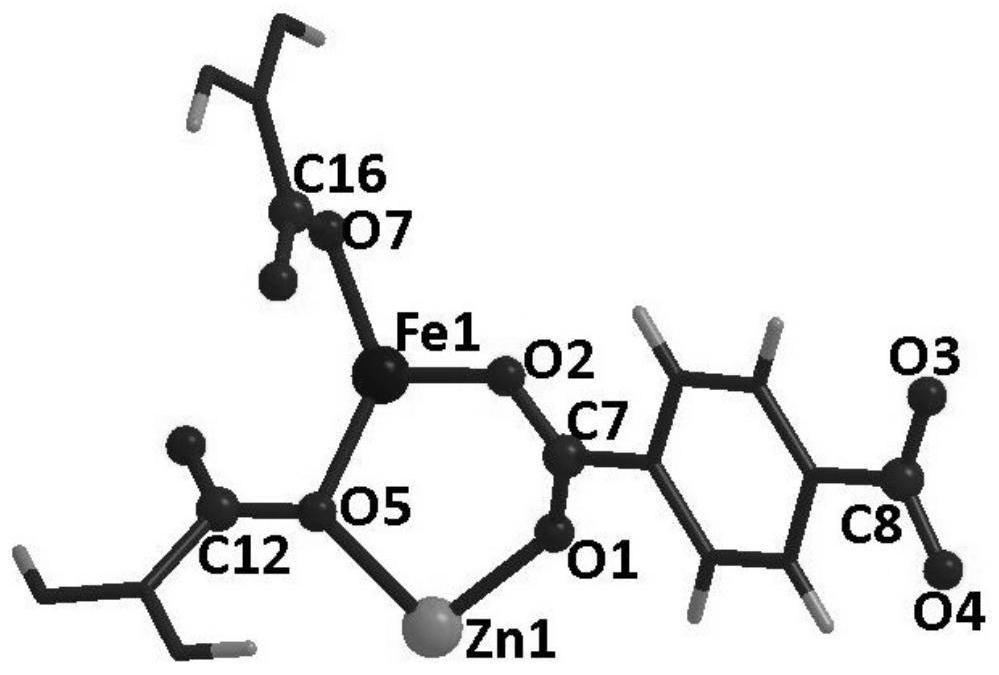

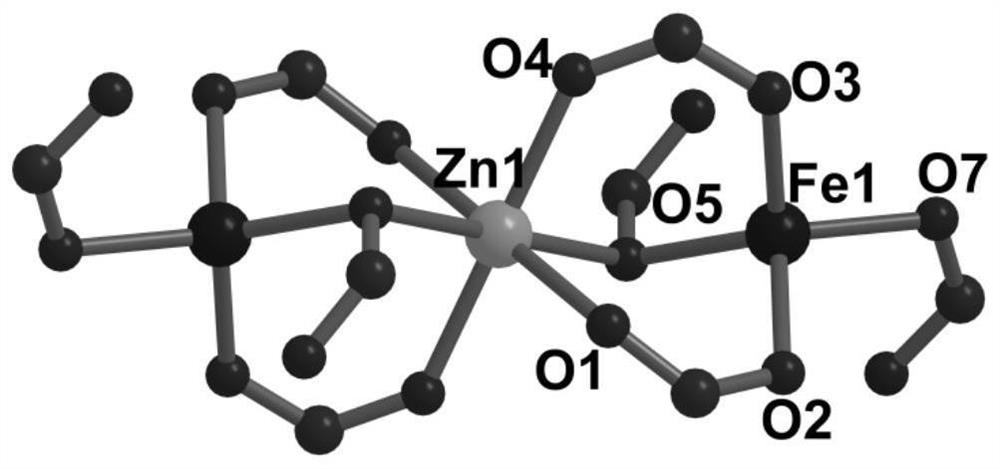

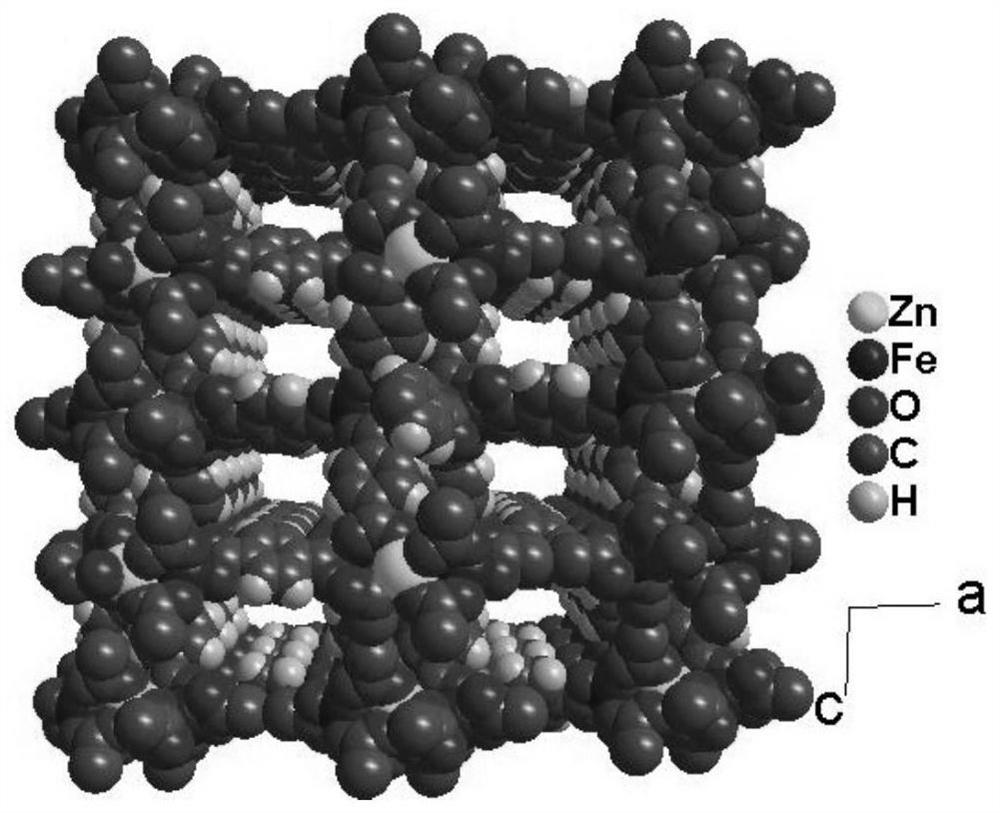

[0030] Embodiment 1: Preparation of bimetallic MOF1 crystalline catalyst

[0031] (1) According to Fe(NO 3 ) 3 9H 2 O and Zn(CCl 3 COO) 2 2H 2 O molar ratio is 1:2 weighing, add 40mL methanol, ultrasonic to make it mix evenly, the reaction solution is transferred to the oil bath and heated to reflux for 7h and then cooled to room temperature, filtered and washed with methanol to obtain the corresponding complex precursor, Molecular formula is Fe III 2 Zn II O(CCl 3 COO) 6 (CH 3 Oh) 3 ;

[0032] (2) According to H 2 BDC and Fe in (1) III 2 Zn II O(CCl 3 COO) 6 (CH 3 Oh) 3 The molar ratio of the complex precursor is 10:1. Weigh the H 2 BDC;

[0033] (3) H 2 BDC and the complex precursor were mixed in DMF (10ml) and n-propanol (0.5mL) under ultrasound or stirring to form a precursor solution, and stirred at room temperature for 30min;

[0034] (4) Transfer the precursor solution obtained in (3) into a hydrothermal kettle with a volume ratio of 1 / 3, and perfo...

Embodiment 2

[0037] Embodiment 2: Preparation of bimetallic MOF1 crystalline catalyst

[0038] (1) According to Fe(NO 3 ) 3 9H 2 O and Zn(CCl 3 COO) 2 2H 2 O molar ratio is 1:2 weighing, add 40mL methanol, ultrasonic to make it mix evenly, the reaction solution is transferred to the oil bath and heated to reflux for 7h and then cooled to room temperature, filtered and washed with methanol to obtain the corresponding complex precursor, Molecular formula is Fe III 2 Zn II O(CCl 3 COO) 6 (CH 3 Oh) 3 ;

[0039] (2) According to H 2 BDC and Fe in (1) III 2 Zn II O(CCl 3 COO) 6 (CH 3 Oh) 3 The molar ratio of the complex precursor is 5:1. Weigh the H 2 BDC;

[0040] (3) H 2 BDC and the complex precursor were mixed in DMF (10ml) and n-propanol (0.5mL) under ultrasound or stirring to form a precursor solution, and stirred at room temperature for 30min;

[0041] (4) Transfer the precursor solution obtained in (3) into a hydrothermal kettle with a volume ratio of 1 / 3, and perf...

Embodiment 3

[0042] Embodiment 3: Preparation of bimetallic MOF1 crystalline catalyst

[0043] (1) According to Fe(NO 3 ) 3 9H 2 O and Zn(CCl 3 COO) 2 2H 2 O molar ratio is 1:2 weighing, add 40mL methanol, ultrasonic to make it mix evenly, the reaction solution is transferred to the oil bath and heated to reflux for 7h and then cooled to room temperature, filtered and washed with methanol to obtain the corresponding complex precursor, Molecular formula is Fe III 2 Zn II O(CCl 3 COO) 6 (CH 3 Oh) 3 ;

[0044] (2) According to H 2 BDC and Fe in (1) III 2 Zn II O(CCl 3 COO) 6 (CH 3 Oh) 3 The molar ratio of the complex precursor is 10:1. Weigh the H 2 BDC;

[0045] (3) H 2 BDC and the complex precursor were mixed in DMF (10ml) and n-propanol (1mL) under ultrasound or stirring to form a precursor solution, and stirred at room temperature for 30min;

[0046] (4) Transfer the precursor solution obtained in (3) into a hydrothermal kettle with a volume ratio of 1 / 3, and perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com