Hydrophobic resin composition and preparation method and application thereof

A technology of hydrophobic resin and composition, applied in the direction of epoxy resin glue, earthwork drilling, adhesive type, etc., to achieve high crushing strength, high water blocking ability, and the effect of preventing closure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

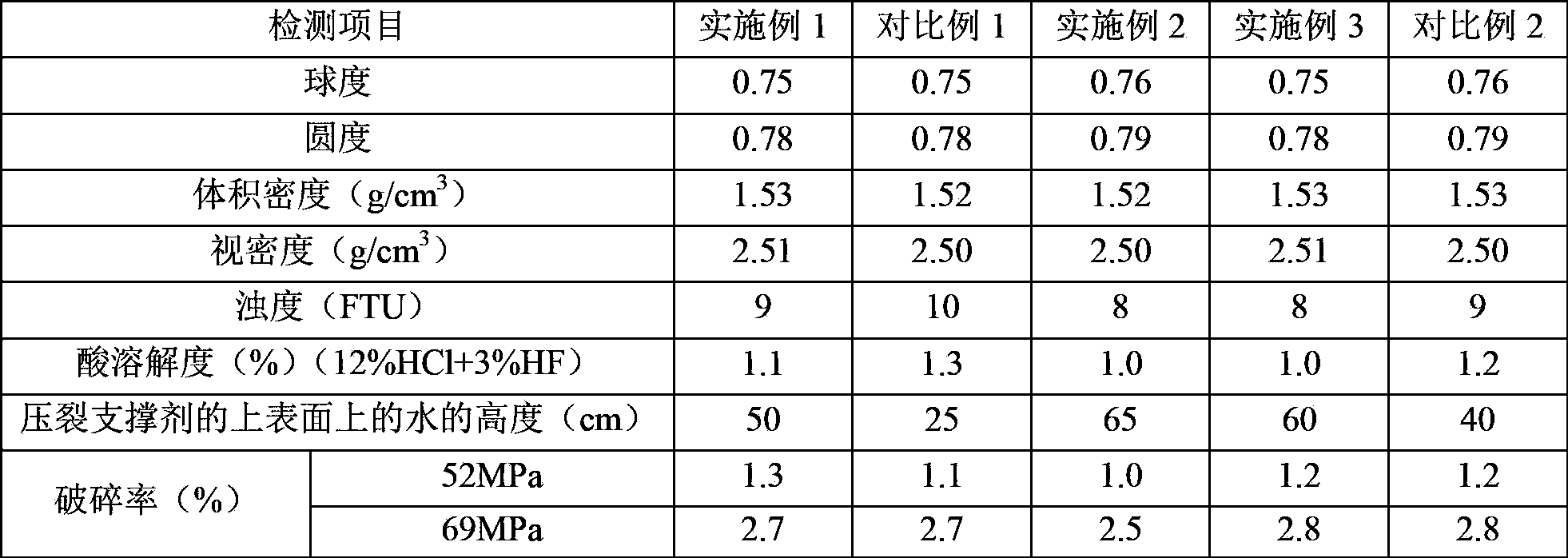

Examples

Embodiment 1

[0049] (1) Dissolve 100g of epoxy resin (commercially purchased from Langfang Nuoerxin Chemical Co., Ltd., brand E-44, epoxy value 0.44mol / 100g, hydroxyl value 0.088mol / 100g) in 50g toluene, with stirring The temperature was raised to 50°C, then 15.3g of toluene diisocyanate was added, and the reaction was stirred at this temperature for 2 hours; then 23g of tetrafluorobutyl ethyl alcohol (commercially purchased from Fuxin Hengtong Fluorine Chemical Co., Ltd., brand name TEOH- 4) After continuing the reaction for 2 hours, the obtained mixture was evaporated under reduced pressure in a rotary evaporator at a temperature of 60° C. to remove toluene, thereby obtaining the hydrophobic resin composition of the present invention.

[0050] (2) Mix 100g of the hydrophobic resin composition obtained in step (1) with 2000g of raw sand (commercially purchased from Jinshengyuan Proppant Co., Ltd., Qingtongxia City, with a particle size of 30-50 mesh) and stir for 2 minutes, then add 40g T...

Embodiment 2

[0054] (1) Dissolve 100g of epoxy resin (commercially purchased from Langfang Nuoerxin Chemical Co., Ltd., brand E-31, epoxy value 0.31mol / 100g, hydroxyl value 0.166mol / 100g) in 50g toluene, with stirring The temperature was raised to 50°C, then 27.6g of cyclohexyl diisocyanate was added, and the reaction was stirred at this temperature for 2 hours; then 43.8g of tetrafluorobutyl ethyl alcohol (commercially purchased from Fuxin Hengtong Fluorine Chemical Co., Ltd., trade name: TEOH-4), after continuing to react for 2 hours, the obtained mixture was evaporated under reduced pressure in a rotary evaporator at a temperature of 60° C. to remove toluene, thereby obtaining the hydrophobic resin composition of the present invention.

[0055] (2) Mix 160g of the hydrophobic resin composition obtained in step (1) with 2000g of raw sand (commercially purchased from Qingtongxia Jinshengyuan Proppant Co., Ltd., with a particle size of 30-50 mesh) and stir for 2 minutes, then add 20g Diami...

Embodiment 3

[0057] (1) Dissolve 100g of epoxy resin (commercially purchased from Langfang Nuoerxin Chemical Co., Ltd., brand E-51, epoxy value 0.51mol / 100g, hydroxyl value 0.046mol / 100g) in 50g toluene, with stirring The temperature was raised to 50°C, then 10.2g of isophorone diisocyanate was added, and the reaction was stirred at this temperature for 2 hours; then 16.9g of perfluorohexyl ethyl alcohol (commercially purchased from Fuxin Hengtong Fluorine Chemical Co., Ltd., brand name TEOH-6), after continuing the reaction for 2 hours, the obtained mixture was evaporated under reduced pressure in a rotary evaporator at a temperature of 60° C. to remove toluene, thereby obtaining the hydrophobic resin composition of the present invention.

[0058] (2) Mix 100g of the hydrophobic resin composition obtained in step (1) with 2000g of raw sand (commercially purchased from Jinshengyuan Proppant Co., Ltd., Qingtongxia City, with a particle size of 30-50 mesh) and stir for 2 minutes, then add 40g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com