Common self-adhesive glue scavenger and production process thereof

A production process and scavenger technology, which is applied in the field of cleaning agents, can solve problems such as environmental pollution, damage to human skin, and damage to cleaned items, and achieve the effects of reduced dosage, fine foam, and good decontamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

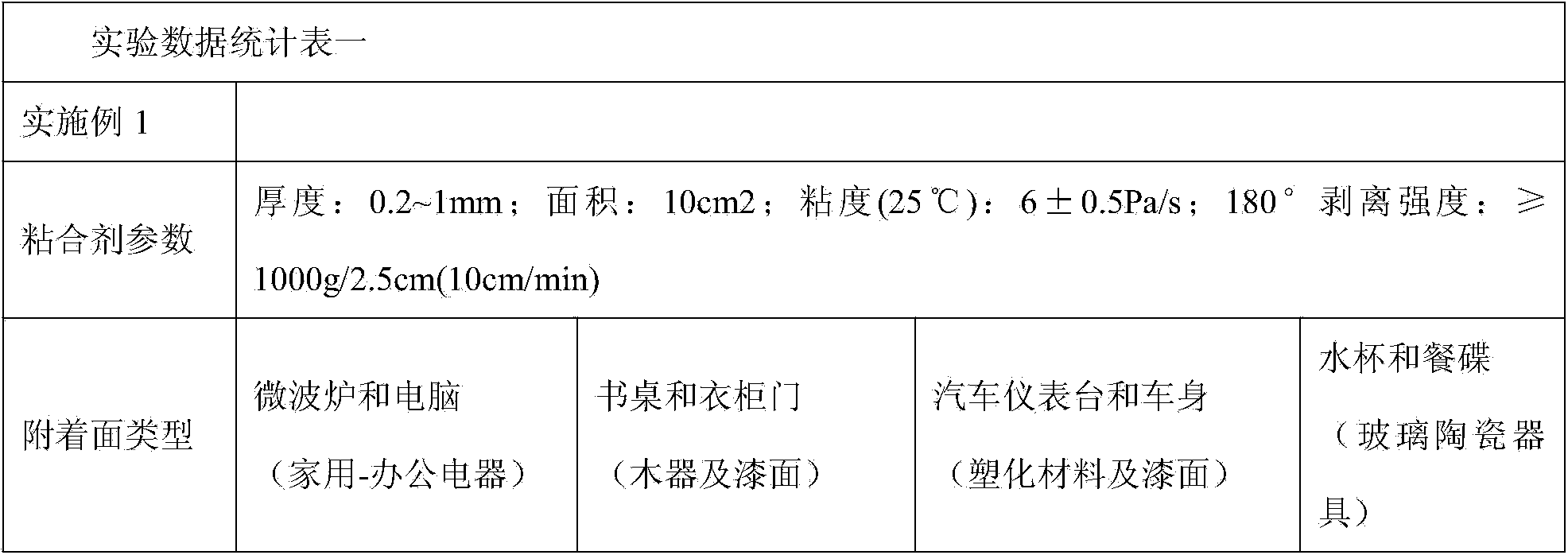

Embodiment 1

[0034] A commonly used adhesive remover provided by the invention is made of the following components: Buckman's sticky matter control enzyme Optimyze 5250.001kg, deionized water 90kg, octadecyl dihydroxyethylamine oxide 7.999kg, 0.5 kg of cocamidopropyl betaine, 0.5 kg of isothiazolinone, and 1 kg of essence (the essence described is the essence commonly used in detergents, such as green apple essence).

Embodiment 2

[0036] Another commonly used adhesive remover provided by the present invention is made of the following components: Buckman's sticky matter control enzyme Optimyze 5300.05kg, deionized water 73.7kg, stearamidopropylamine oxide 20kg, coconut oil Amidopropyl betaine (CAB-30) 5kg, isothiazolinone 0.25kg, essence 1kg.

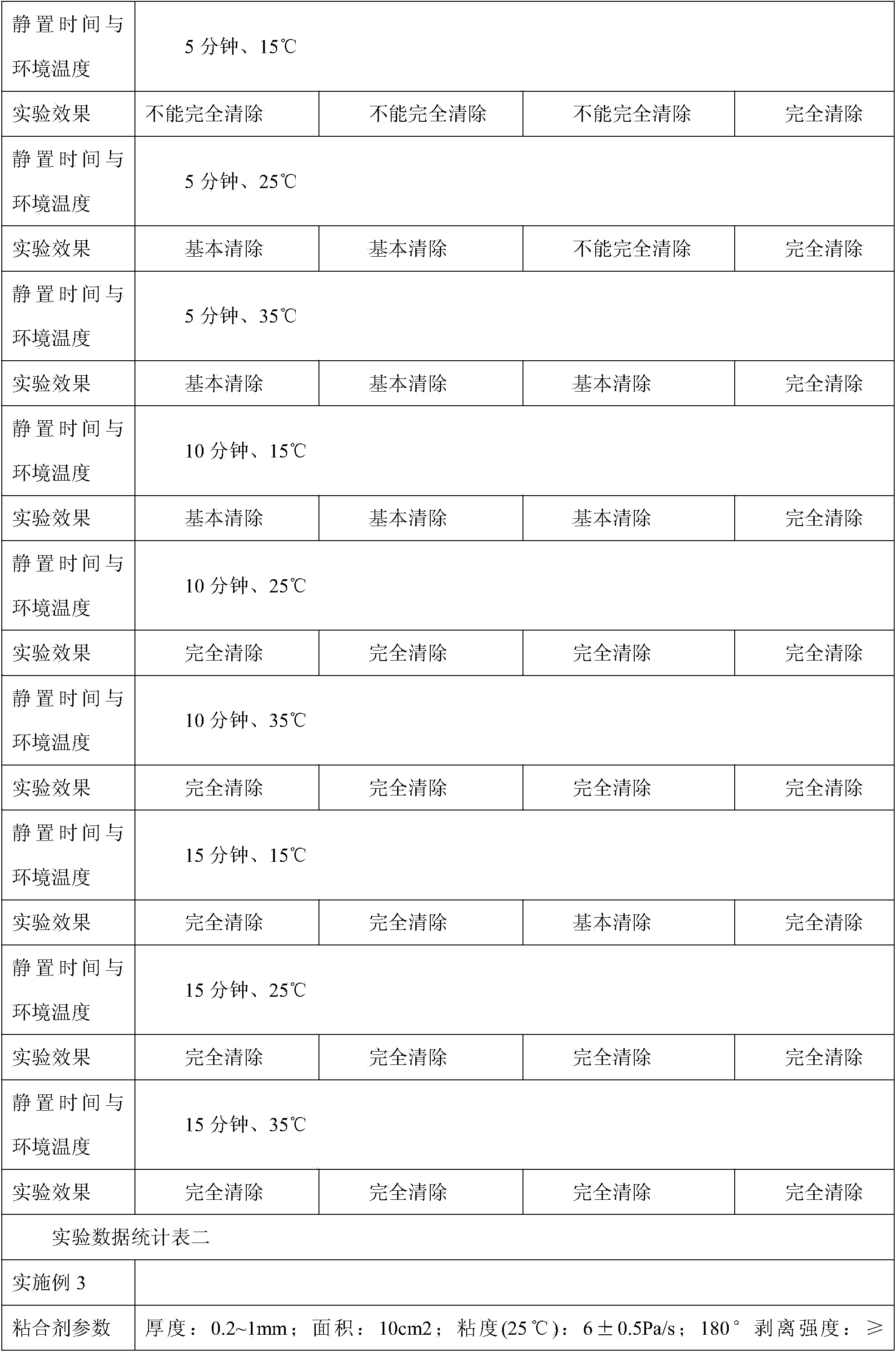

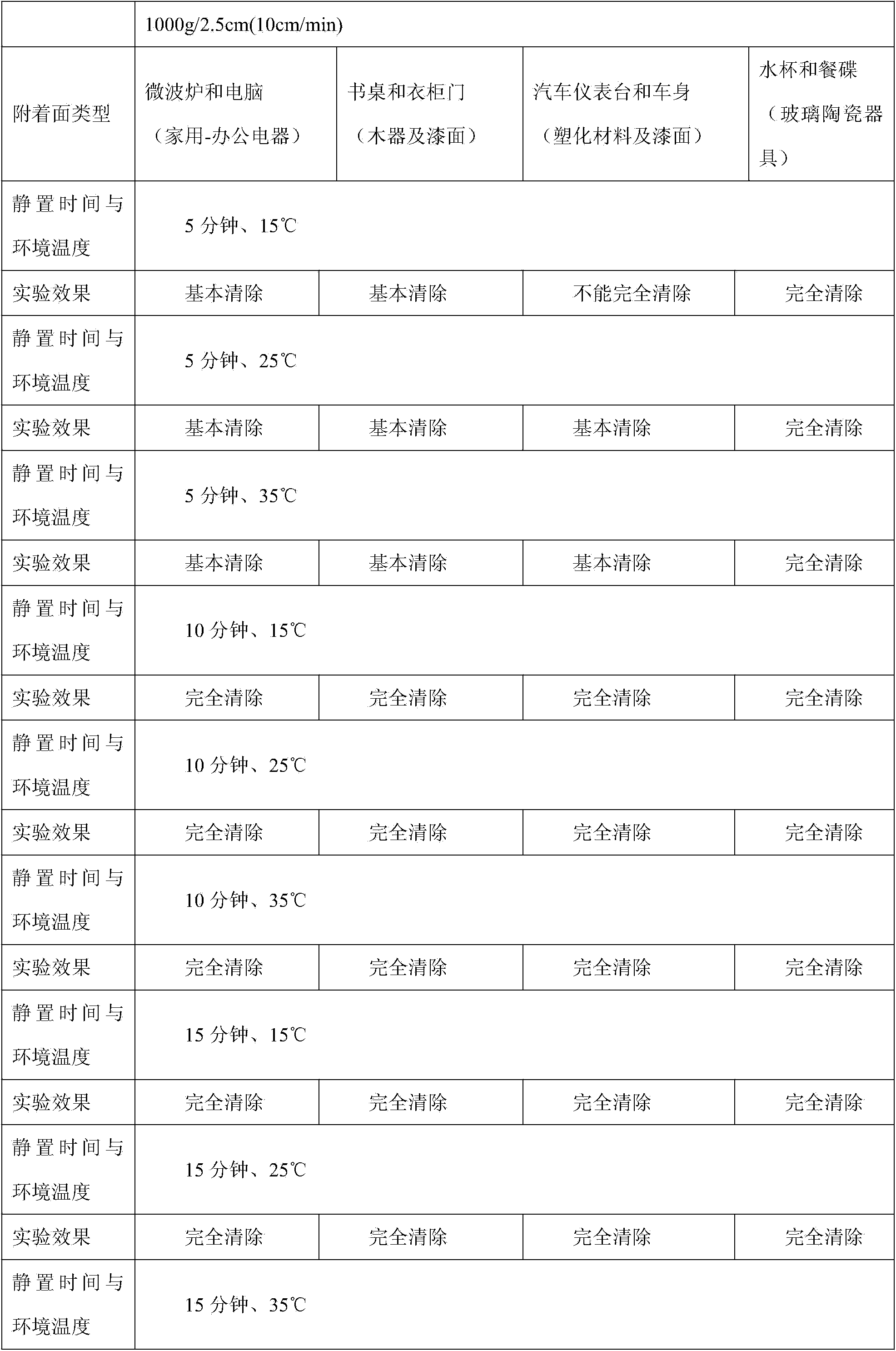

Embodiment 3

[0038] Another commonly used adhesive remover provided by the present invention is made of the following components: Buckman sticky matter control enzyme Optimyze 5400.1kg, deionized water 58.5kg, octadecyl dihydroxyethyl amine oxide 10kg , lauryl amidopropyl amine oxide 10.8kg, cocamidopropyl betaine 20kg, isothiazolinone 0.1kg, lemon essence 0.5kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com