A solid particle fuel boiler

A solid particle and fuel technology, applied in the field of solid particle fuel boilers, can solve the problems of insufficient release of fuel energy, gas explosion in the ventilation pipe, and potential safety hazards, so as to avoid backfire phenomenon, prolong service life and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

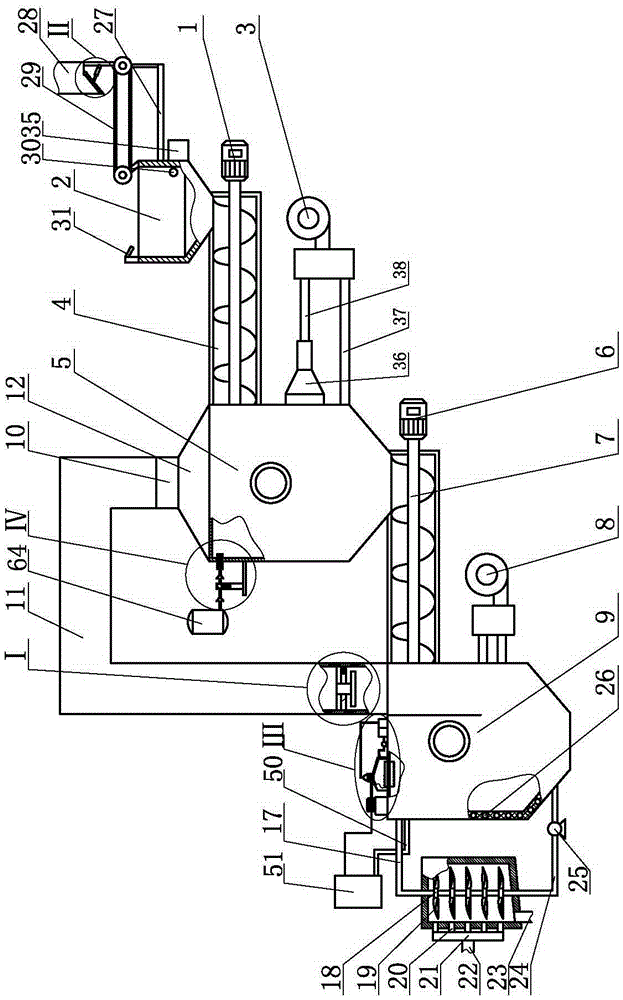

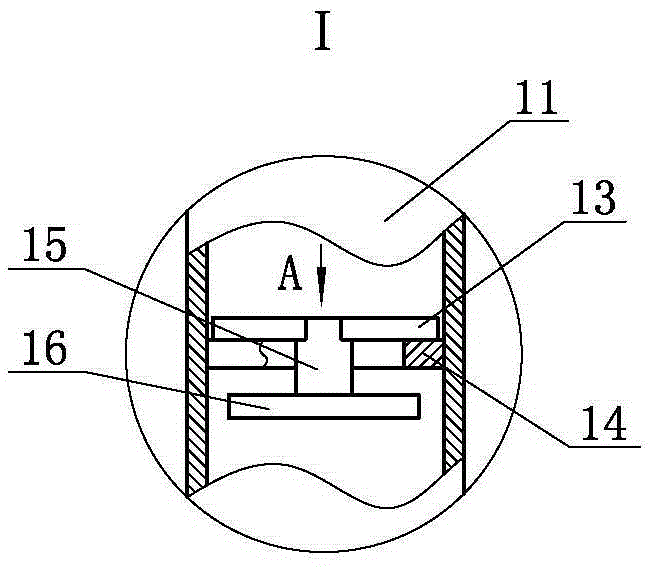

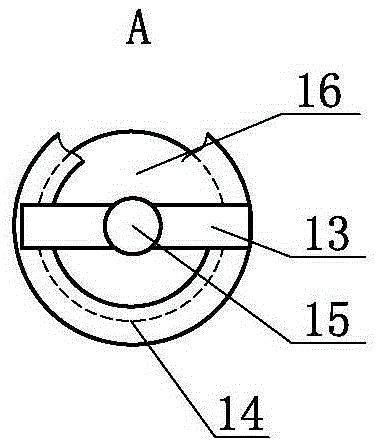

[0009] A solid pellet fuel boiler such as figure 1As shown, the first hopper 2 is included, and the biomass pulverized particles or sawdust are thrown into the present invention through the first hopper 2. The lower end of the first hopper 2 is connected to the feed port of the first stirring cage 4, and the discharge of the first stirring cage 4 The outlet is connected to the first combustion furnace 5, and the pulverized particles or wood chips are transported to the first combustion furnace 5 by the stirring cage 4. The shaft of the first stirring cage 4 is connected to the first motor 1, and the furnace chamber of the first combustion furnace 5 is connected to the first fan. 3. The first fan 3 is ventilated into the first combustion furnace 5, the bottom of the first combustion furnace 5 is connected to the feed port of the second stirring cage 7, and the discharge port of the second stirring cage 7 is connected to the second combustion furnace 9. The shaft of the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com