A method for detecting the static pressure difference failure of dust collection filter based on temperature correction

A detection method, static pressure difference technology, applied in the direction of machine/structural component testing, measuring devices, instruments, etc., to achieve the effect of overcoming false alarms, strong sensitivity and robustness, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the content of the present invention clearer and easier to understand, the present invention will be further described below through specific embodiments of the present invention.

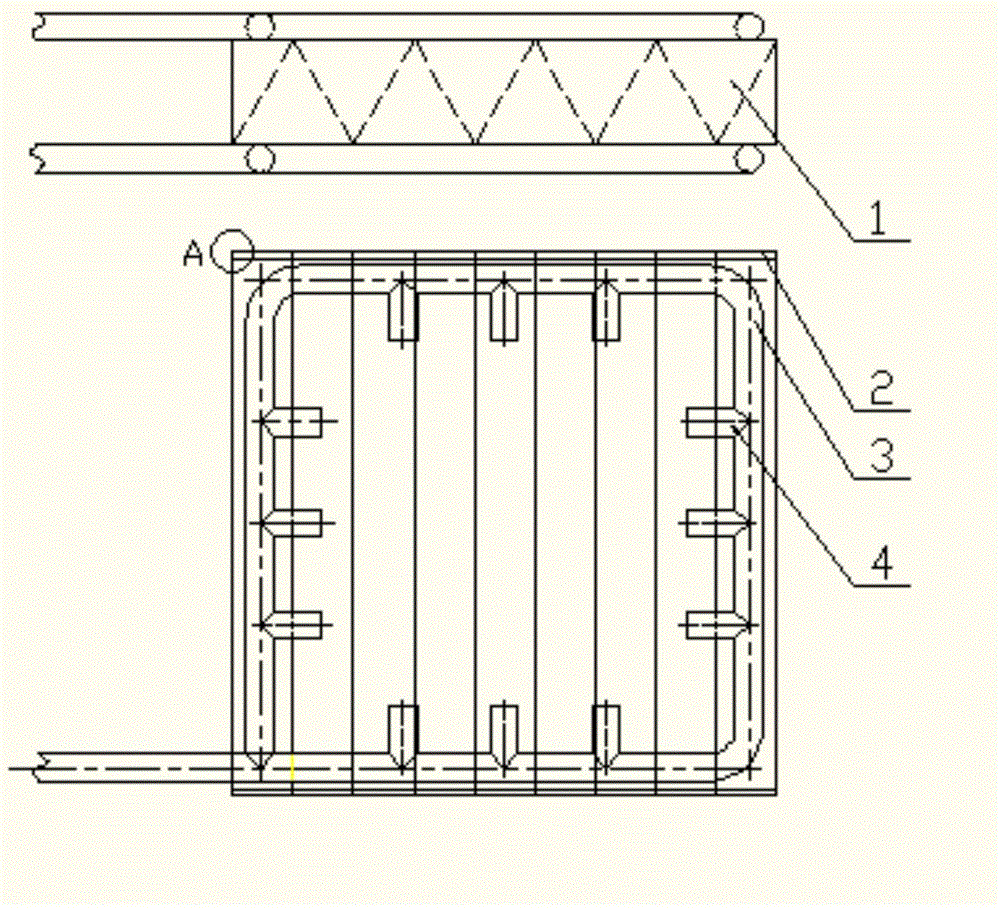

[0020] The implementation method is first as figure 1 The shown hardware structure block diagram establishes a static pressure difference detection hardware system. On the basis of not changing the overall structure of the air cleaner, the present invention adds a pressure acquisition device 2 with a special layout at its net outlet 1, and utilizes the relevant pipeline 3 to draw out the measurable Static pressure difference. The standard electric signal of the static pressure difference is obtained through the high-precision differential pressure sensor 4 with a suitable range, and the relevant software is compiled to realize the computer acquisition, filtering and recording of the original data of the static pressure difference. / D conversion acquisition equipment collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com