Method for measuring contact angle and surface energy of cement-based material

A technology of cement-based material and measurement method, applied in the field of civil engineering, can solve the problems of affecting the stability of the contact angle, difficult to judge the surface properties, change of the time of the contact angle measurement, etc., so as to achieve the effect of overcoming unfavorable factors and avoiding adverse effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 1) Sample: a plain concrete test block prepared in a steel mold (specification: 4cm*4cm*4cm) with 525 composite portland cement produced by Shenzhen Haixing Onoda Cement Co., Ltd., the mix ratio is: water-cement ratio 0.4, Fly ash 0.6, slag 0.1, 120d curing under standard environment, take 2 samples for contact angle measurement.

[0062] 2) Sample surface treatment: Firstly, use a pre-grinder to grind the surface of two samples with 500 mesh, 1000 mesh, and 2000 mesh sandpaper in sequence, and each sample is polished for 5 minutes on each specification of sandpaper at a set speed of 550r / min; then use Microfiber dust-free cloth (manufacturer: Shenzhen Honglian Purification Technology Co., Ltd., model: 4009-6, specification: 15cm*15cm) to wipe the polished surface, clean the surface dust and other tiny impurities; finally put the sample in Fully infiltrate in pure water to expel the air in the pores of the sample.

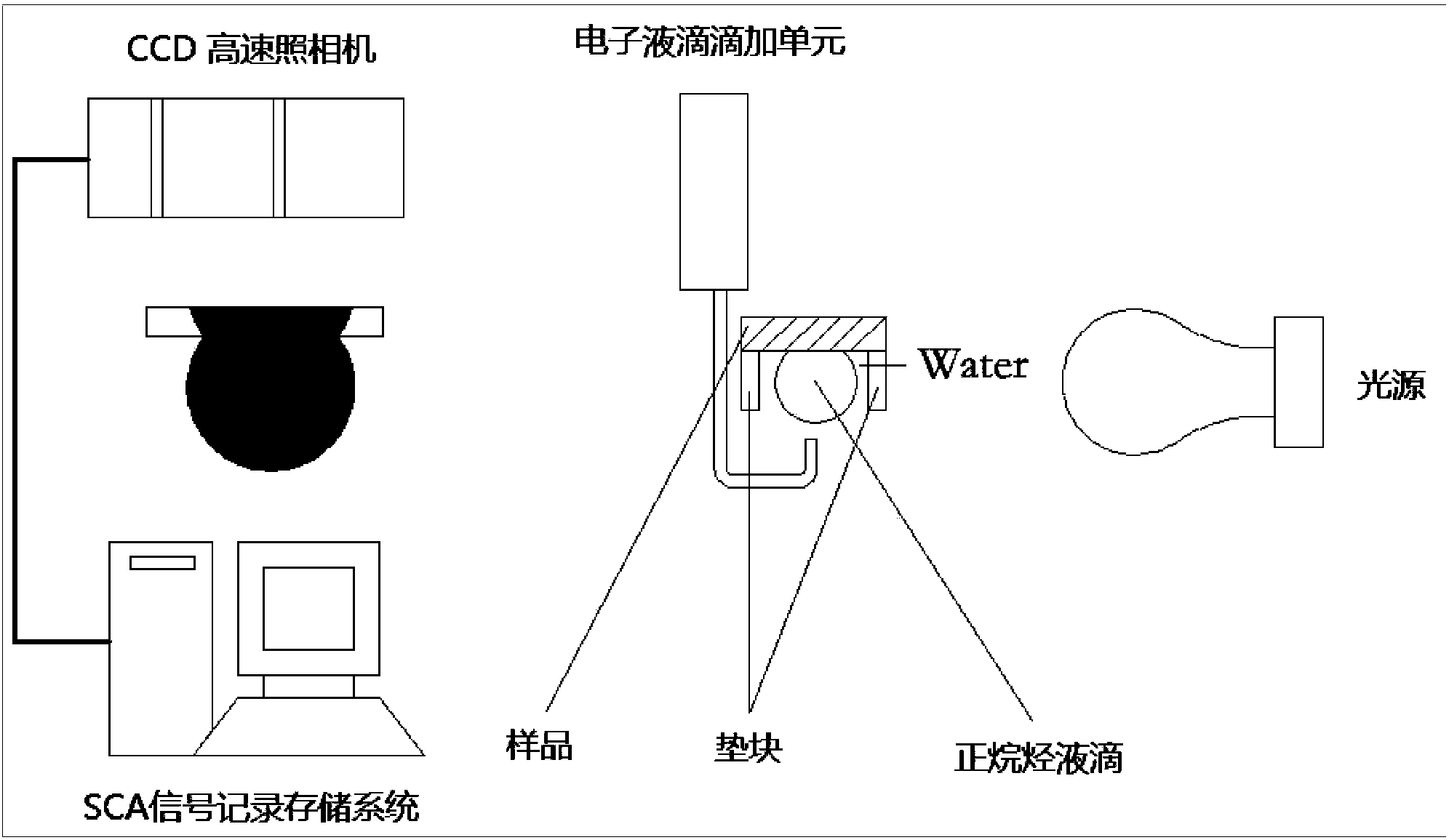

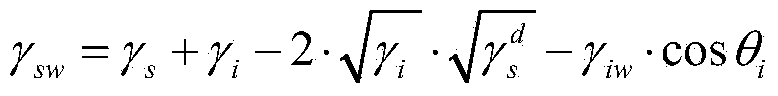

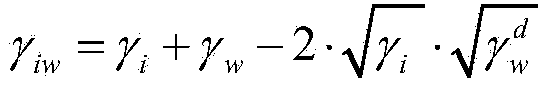

[0063] 3) Test: Measure the contact angle of sample-p...

Embodiment 2

[0077] 1) Sample: a plain concrete test block prepared in a steel mold (specification: 4cm*4cm*4cm) with 525 composite portland cement produced by Shenzhen Haixing Onoda Cement Co., Ltd., the mix ratio is: water-cement ratio 0.4, Fly ash 0.2, slag 0.3, 120d curing under standard environment, 4 samples were taken for contact angle measurement.

[0078] 2) Surface treatment of the sample: First, use a pre-grinder to grind the surface of 4 samples with 500 mesh, 1000 mesh, and 2000 mesh sandpaper in sequence, and each sample is polished for 5 minutes on each specification of sandpaper at a set speed of 550r / min; then use Microfiber dust-free cloth (manufacturer: Shenzhen Honglian Purification Technology Co., Ltd., model: 4009-6, specification: 15cm*15cm) to wipe the polished surface, clean the surface dust and other tiny impurities; finally put the sample in Fully infiltrate in pure water to expel the air in the pores of the sample.

[0079] 3) Test: Measure the contact angle of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com