Method for ultrasonically testing coupling quality of multilayered media

A multi-layer medium and ultrasonic detection technology, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can solve the problems that the electromagnetic wave radar method cannot be used for detection, it is not suitable for large-scale detection, and it is impossible to install transducers. Low, improve the resonance frequency, the effect of simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

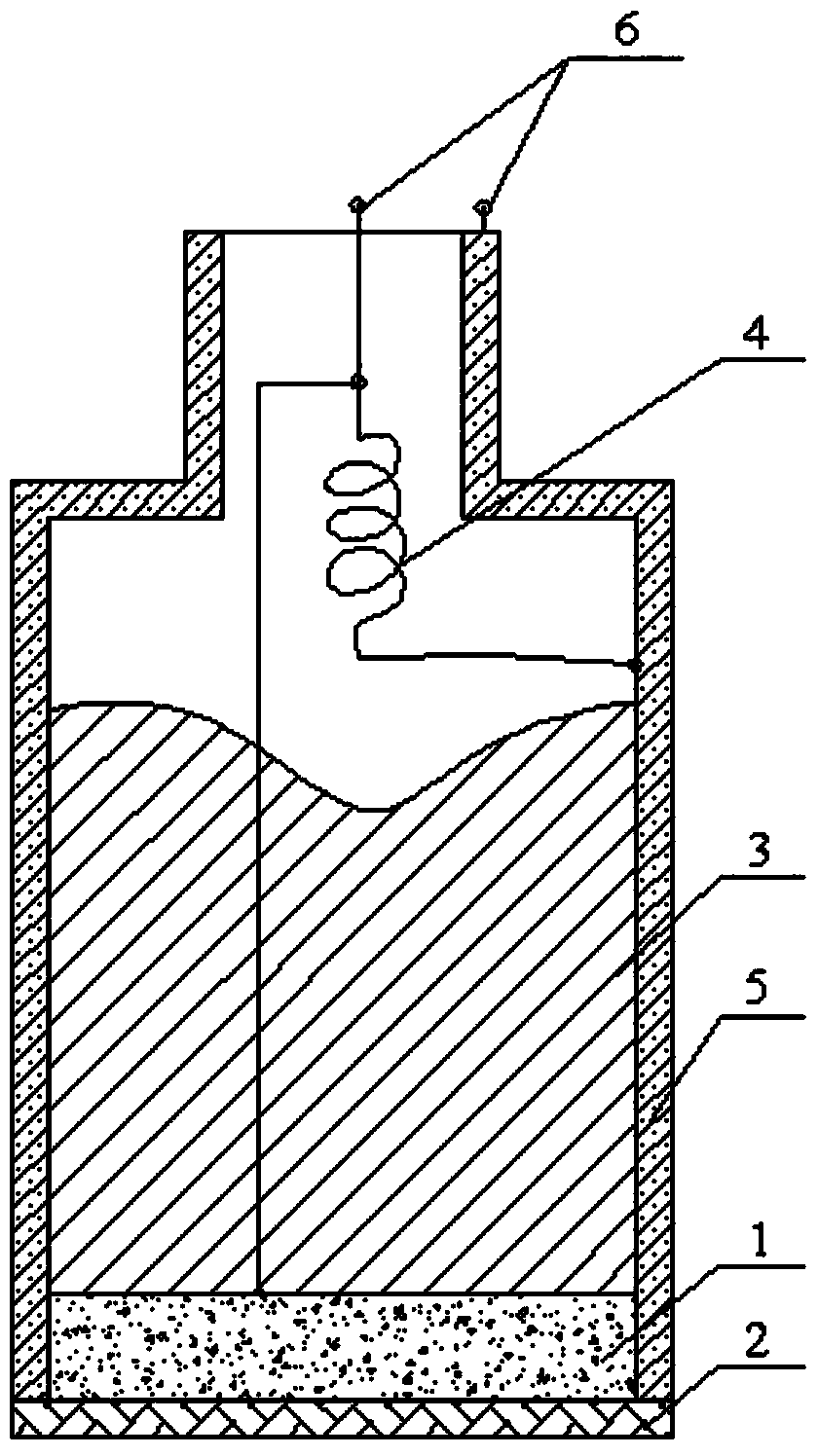

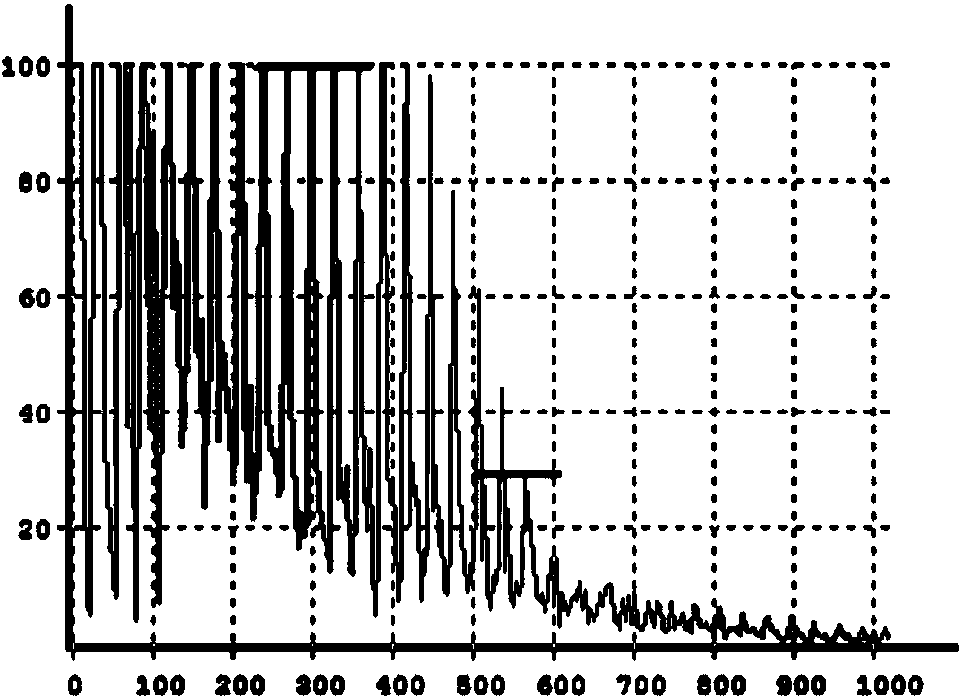

[0054] In the construction process of underground structure reinforcement, the design usually adopts different reinforcement measures according to different structures and different needs. The anti-corrosion materials selected are also different, and the material thickness is also different. Therefore, different types of reinforcement measures (similar in form) , There are also differences in the waveform spectrum of ultrasonic testing of the coupling quality of multi-layer media.

[0055] A method for detecting the coupling quality of multi-layer media with ultrasonic waves, the method comprises the following steps:

[0056] (1) Improve the performance of the probe and improve the performance of the ultrasonic testing instrument;

[0057] The specific methods to improve the performance of the probe are as follows:

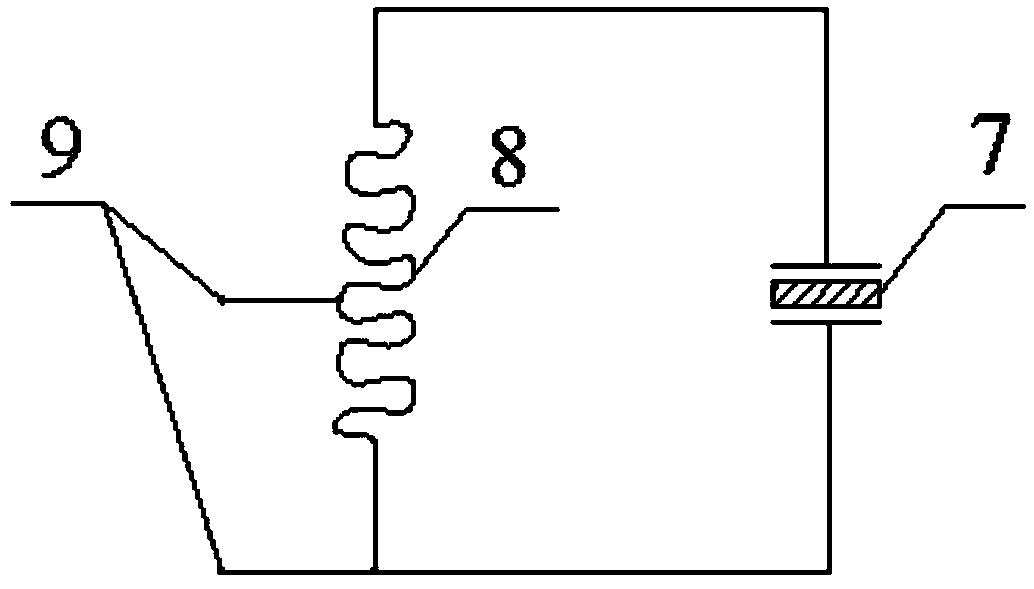

[0058] 1) Change the structure of the probe, connect the inductor in parallel in the probe, improve the electrical impedance characteristics of the probe, and ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com