Fluoroplastic base material composite material used in electronic device and used for extinguishing arc

A composite material and fluoroplastic technology, applied in the field of arc extinguishing composite materials, can solve the problems of easy carbonization, fracture and softening of materials, and achieve the effect of reducing the risk of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Preparation method of composite material

[0049] The method for preparing the composite material of the present invention needs to adjust the processing route according to the type of fluororesin. For the preparation of PTFE-based composites, powder processing methods are preferred. Specifically, the PTFE and the filler are first dry-blended and mixed evenly, and then the mixed powder is processed by molding and sintering to obtain the composite material. For the preparation of composite materials based on several other fluororesins, it can be directly prepared by conventional extrusion molding methods in this field.

[0050] Arc extinguishing principle of composite materials

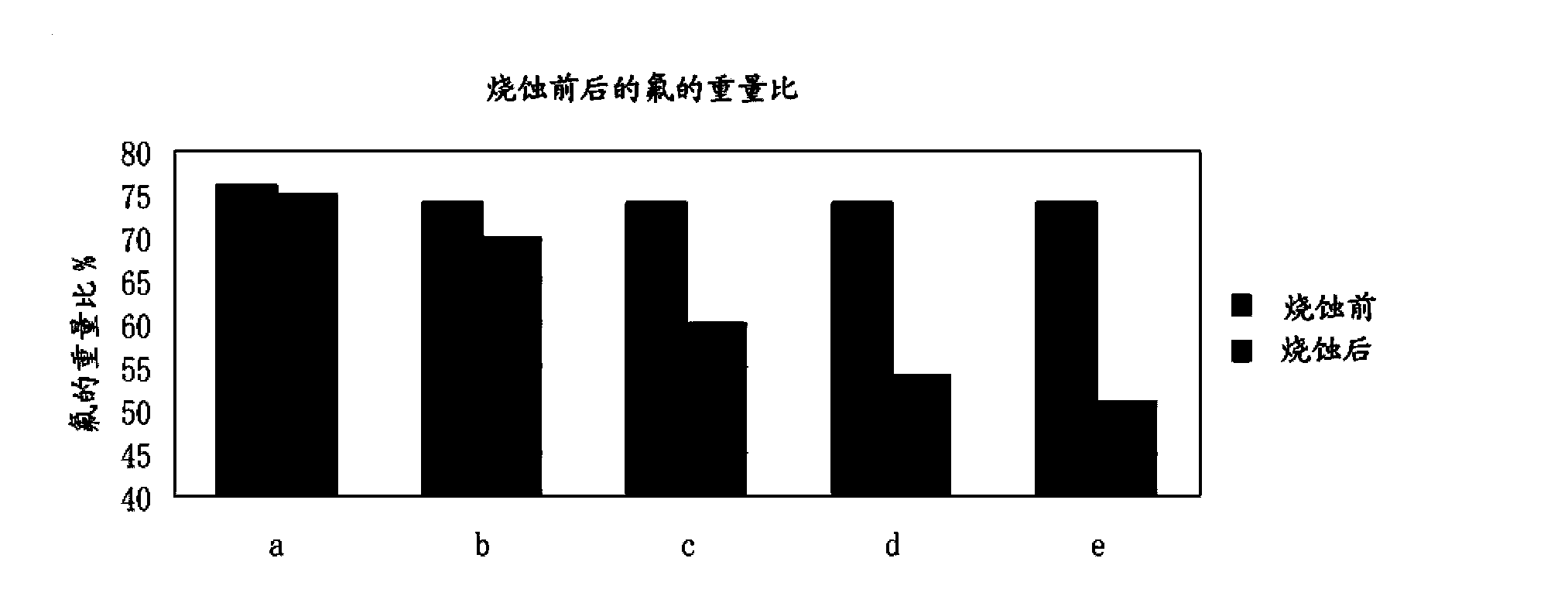

[0051] Unlike the arc filled with SF which has high insulation and arc extinguishing performance 6 , the present invention fills the environment-friendly gas around the arc, and only releases an appropriate amount of electronegative elements (fluorine) into the gas when the arc is generated t...

Embodiment 1

[0066] Embodiment 1: containing 5% CaF 2 Preparation of PTFE Composites

[0067] Add CaF to PTFE powder with a particle size of 20μm-50μm 2 Powder (accounting for 5% of the total mass of the composite material), dry-blended to make it evenly mixed. The mixed powder was then hydrostatically pressed into a cylindrical blank and treated in an oven for 48 hours. Finally, the cylindrical composite material is turned into a strip to obtain PTFE+5%CaF 2 composite products.

Embodiment 2

[0068]Example 2: Containing 5% CeF 3 Preparation of PTFE Composites

[0069] Using the method described in Example 1, using PTFE powder and CeF with a particle size of 20 μm-50 μm 3 Powder (accounting for 5% of the total mass of the composite material) made PTFE+5%CeF 3 composite products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

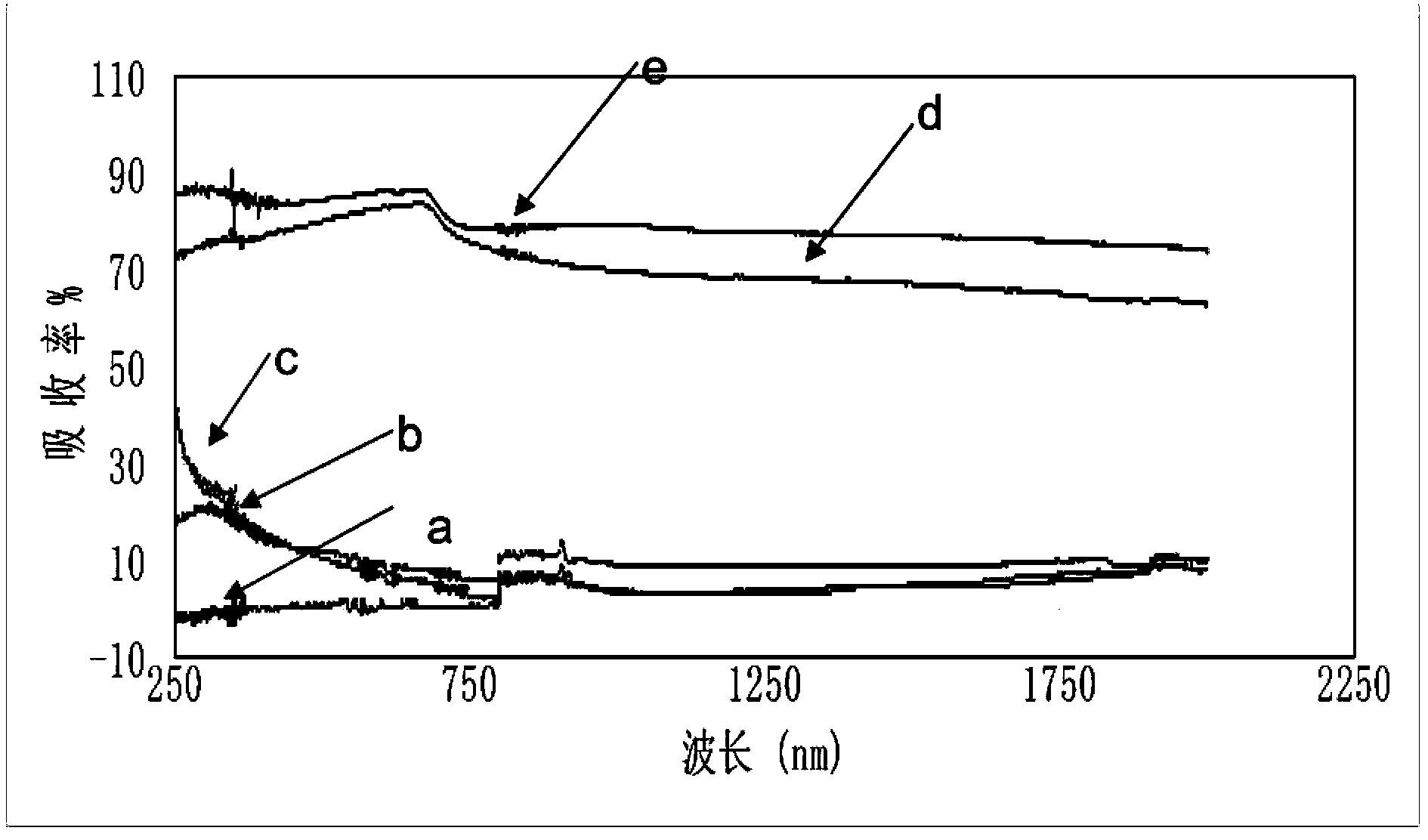

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com