Plastic lens

A technology of plastic lenses and compounds, used in glasses/goggles, instruments, optics, etc., to achieve excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

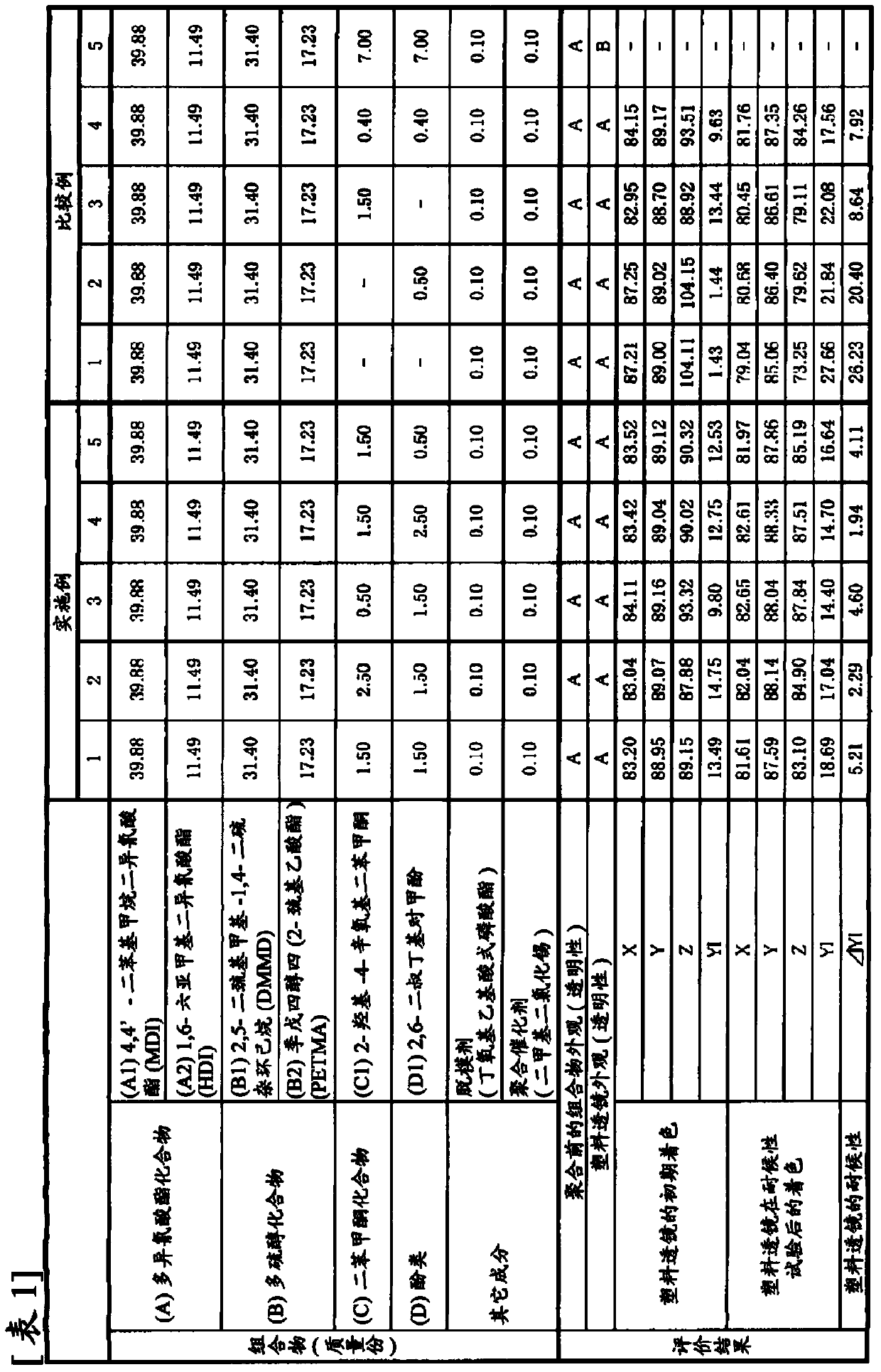

Embodiment 1~5 and comparative example 1~5

[0066] (1) Appearance evaluation (transparency) of the composition before polymerization

[0067] The compositions described in Examples and Comparative Examples were prepared, 50 ml of monomers before polymerization were put into a colorimetric tube (for 50 ml), and the transparency was evaluated under fluorescence in a dark room. The evaluation of each component in the composition is compatible and transparent is "A", and when the composition is cloudy or insoluble components such as (C) and / or (D) components are present, it is evaluated as "B" ".

[0068] (2) Appearance (transparency) of plastic lens

[0069] The appearance of the plastic lenses produced by the methods described in Examples and Comparative Examples was visually observed, and the evaluation was "A" when no turbidity occurred, and "B" when turbidity occurred.

[0070] (3) Evaluation of weather resistance of plastic lenses

[0071] For the D-000 plastic lens (ct2.0mm) that is made by the method described in...

Embodiment 1

[0075] 39.88 g of (A1) 4,4'-diphenylmethane diisocyanate (MDI) which is (A) a polyisocyanate compound having an aromatic ring and 39.88 g of a polyisocyanate compound which does not have an aromatic ring were placed in a 300 ml eggplant-shaped flask. (A2) 11.49 g of 1,6-hexamethylene diisocyanate (HDI), 1.50 g of (C1) 2-hydroxy-4-octyloxybenzophenone as (C) benzophenone compound, and (D) phenolic (D1) 1.50 g of 2,6-di-tert-butyl-p-cresol, butoxy ethyl acid phosphate (trade name "JP-506H", Johoku Chemical Co., Ltd. ) 0.10 g, 0.10 g of dimethyl tin dichloride as a polymerization catalyst, and stirring was continued for 10 minutes under nitrogen purging at 50°C. When they were completely dissolved, 31.40 g of (B1) 2,5-dimercaptomethyl-1,4-dithiacyclohexane (DMMD) and (B2) pentaerythritol tetra( 2-Mercaptoacetate) (PETMA) 17.23 g was stirred under reduced pressure at 0.13 kPa (1.0 Torr) for 20 minutes to prepare Composition 1.

[0076] The composition 1 was poured into a lens mo...

Embodiment 2

[0078] A plastic lens was produced in the same manner as in Example 1 except that the added amount of (C1) 2-hydroxy-4-octyloxybenzophenone was 2.50 g. The evaluation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com