Chassis and method for producing chassis

A manufacturing method and technology for a bottom plate, which are applied to chemical instruments and methods, manufacturing tools, circuit layout on conductive chassis, etc., can solve the problems of increasing the number of components and increasing the thickness of portable devices, and achieve the effect of suppressing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment )

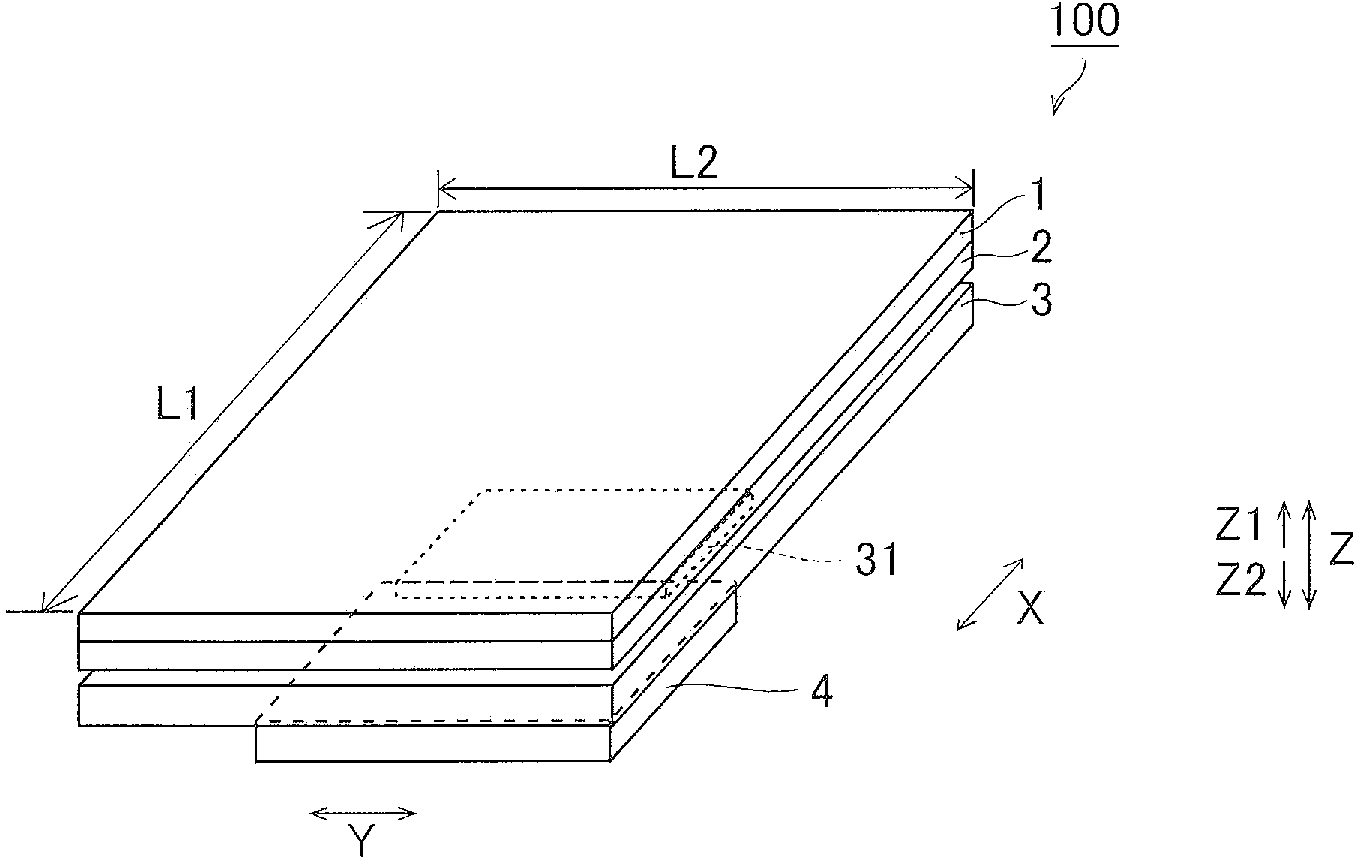

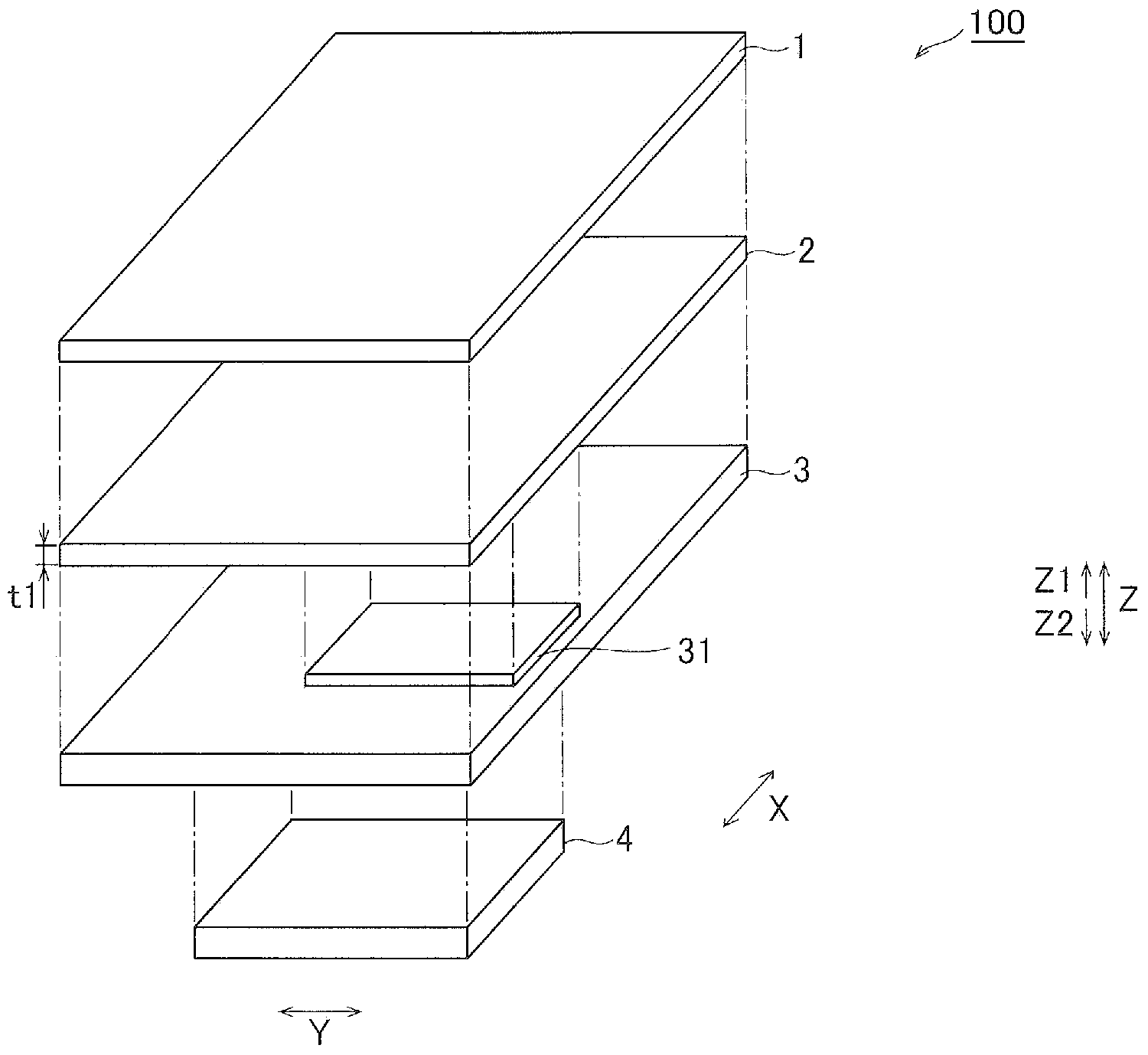

[0086] Next, refer to figure 2 , image 3 , Figure 5 ~ Figure 10 Describes the measurement of heat dissipation performance and the measurement of mechanical strength to confirm the effects of the present invention. However, unless otherwise specified, "thickness" and "plate thickness" mean average values.

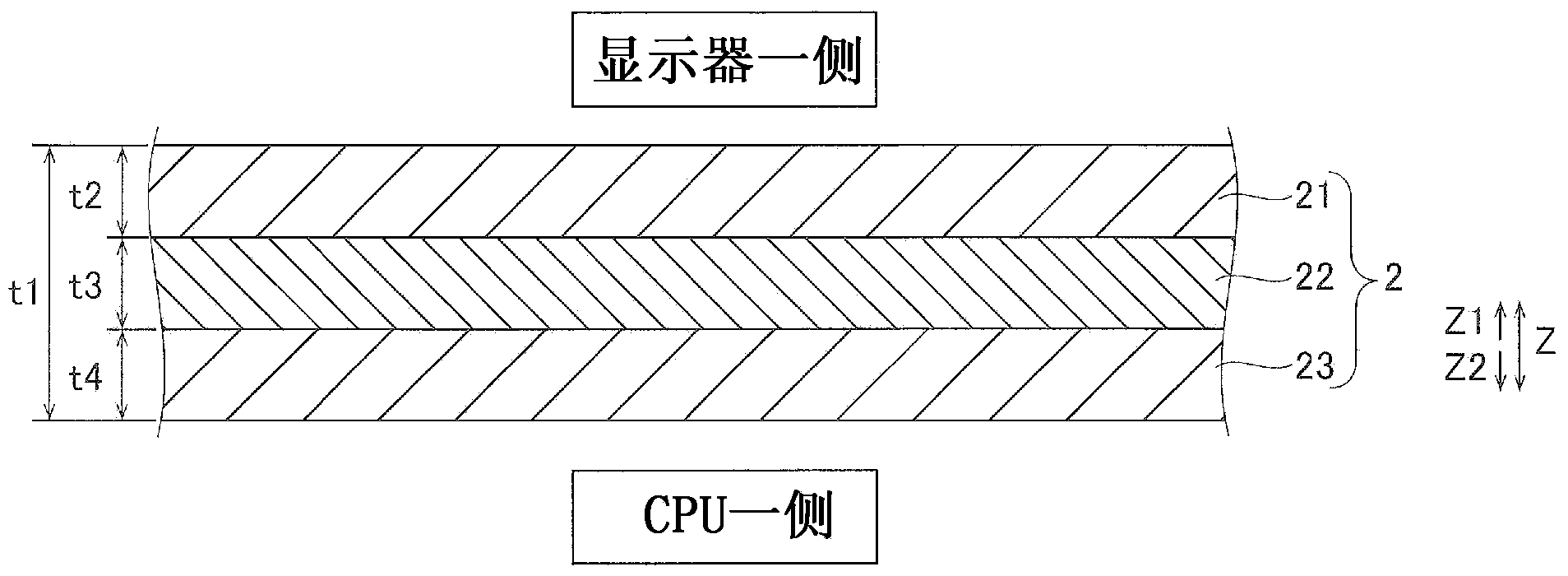

[0087] In this embodiment, use image 3 The bottom plate 2 of the above embodiment is shown. Specifically, Examples 1 to 8 (reference Figure 7 ) A base plate 2 made of a composite material obtained by stacking the SUS layer 21 formed of SUS304, the Cu layer 22 formed of Cu, and the SUS layer 23 formed of SUS304 in this order. In addition, Examples 9 to 13 (reference Figure 8 ) A base plate 2 made of a composite material obtained by stacking the SUS layer 21 formed of SUS301, the Cu layer 22 formed of Cu, and the SUS layer 23 formed of SUS301 in this order.

[0088] In addition, in Examples 1 to 13, the thickness t1 (=t2+t3+t4, total thickness) of the bottom plate 2 was 0.3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| directional tensile yield strength | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com