Production method of silage

A technology of silage and production method, which is applied in animal feed, animal feed, application, etc., can solve the problems of silage nutrition loss and large amount of additives, and achieve the effects of reducing nutrient loss, low cost and good palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

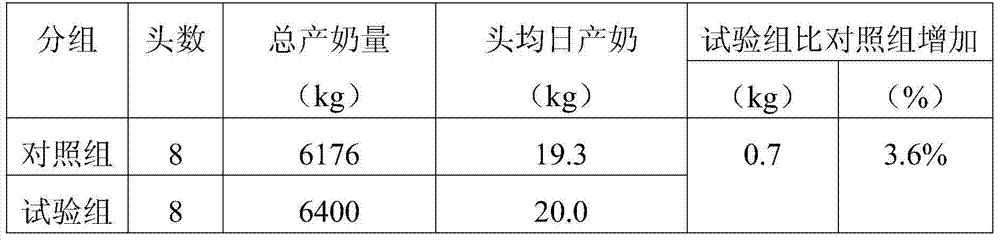

Examples

Embodiment 1

[0038] (1) Preparation of fermented material:

[0039] Take fresh grass, dry it until the water content is 75%, cut into sections according to the length of each section of 1.5cm, and press 10 8 Add lactic acid bacteria preparation in cfu / kg, fill in the silage pond after stirring evenly, seal after compaction layer by layer, obtain fermented material after 15 days of fermentation; Described fermented material is the high-quality silage material containing lactic acid bacteria, organic acid;

[0040] (2) Harvest fresh grass and cut into sections:

[0041] Harvest fresh pasture, spread it flat on the ground, let it dry for 2 hours until the water content is 75%, and then immediately send it to the silage pond for cutting, and cut into sections according to the length of each section of 1.5cm;

[0042] (3) Add fermented material, mix and break:

[0043] While cutting the fresh pasture in step (2), add the fermented material in step (1) to the pasture to be stored according to ...

Embodiment 2

[0049] (1) Preparation of fermented material:

[0050] Take fresh grass, dry it until the water content is 70%, cut it into sections according to the length of each section of 1.4cm, and press 10 8 Add lactic acid bacteria preparation in cfu / kg, stir evenly, fill in the silage tank, seal after compacting layer by layer, and obtain the fermented material after 16 days of fermentation; the fermented material is high-quality silage containing lactic acid bacteria and organic acid;

[0051] (2) Harvest fresh grass and cut into sections:

[0052] Harvest fresh pasture, spread it flat on the ground, let it dry for 1 hour until the water content is 70%, and then immediately send it to the silage pond for cutting, and cut into sections according to the length of each section of 1.5cm;

[0053] (3) Add fermented material, mix and break:

[0054] While cutting the fresh grass in step (2), add the fermented material in step (1) to the grass to be stored according to the weight ratio of...

Embodiment 3

[0060] (1) Preparation of fermented material:

[0061] Take fresh grass, dry it until the water content is 71%, cut into sections according to the length of each section of 1.6cm, and press 10 8 cfu / kg was added into the lactic acid bacteria preparation, stirred evenly, filled into the silage tank, compacted layer by layer, sealed, and fermented for 17 days to obtain the fermented material;

[0062] (2) Harvest fresh grass and cut into sections:

[0063] Harvest fresh pastures, spread them flat on the ground, let them dry for 3 hours until the water content is 71%, and then immediately send them to the silage tank for cutting, and cut them into sections according to the length of each section of 1.6cm;

[0064] (3) Add fermented material, mix and break:

[0065] While cutting the fresh grass in step (2), add the fermented material in step (1) to the grass to be stored according to the weight ratio of fresh grass and fermented material at 1:0.08, and then use the silage chopp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com