An integral drip irrigation belt

A drip irrigation belt, integrated technology, applied in the direction of spray device, horticulture, botany equipment and methods, etc., can solve the problems of high processing cost, high user procurement cost, complex quality control, short laying length, etc., to improve the anti-clogging ability, The effect of simple quality control and few processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

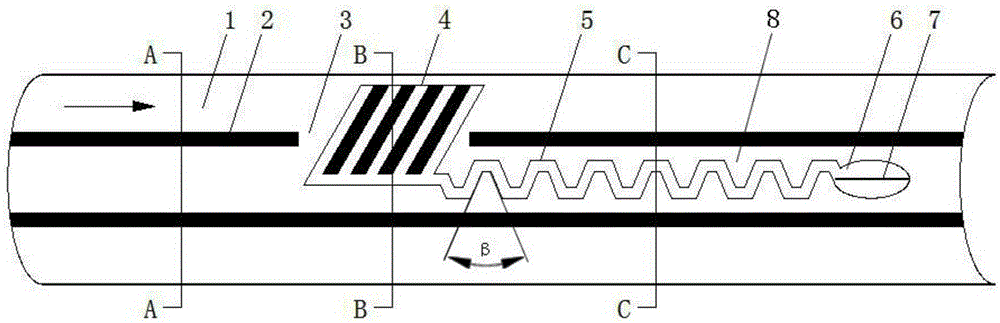

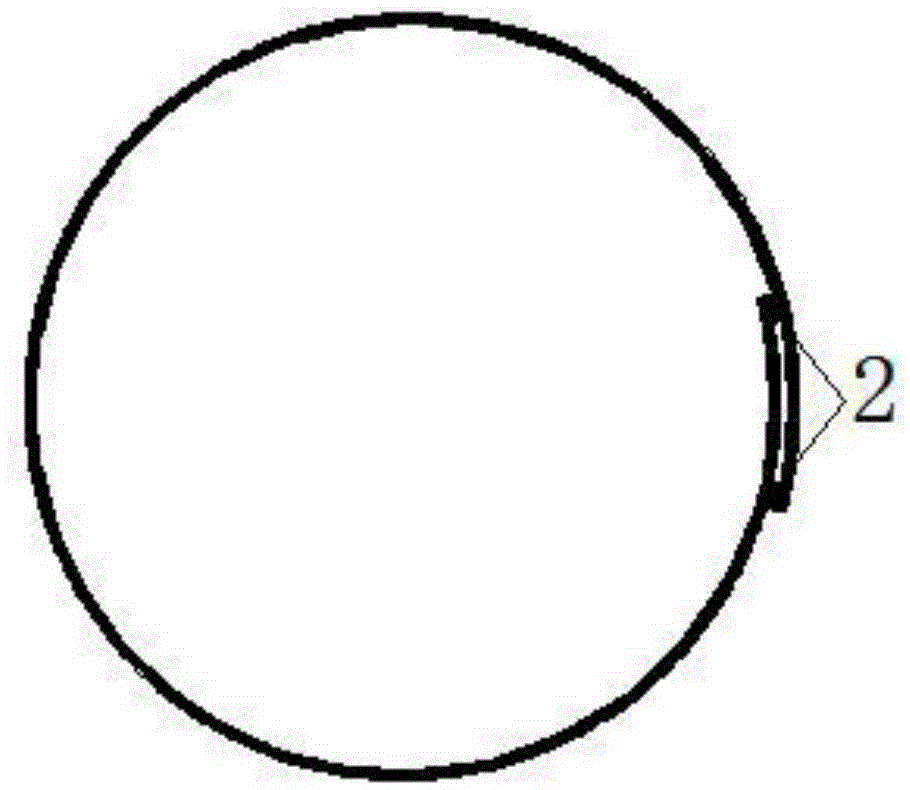

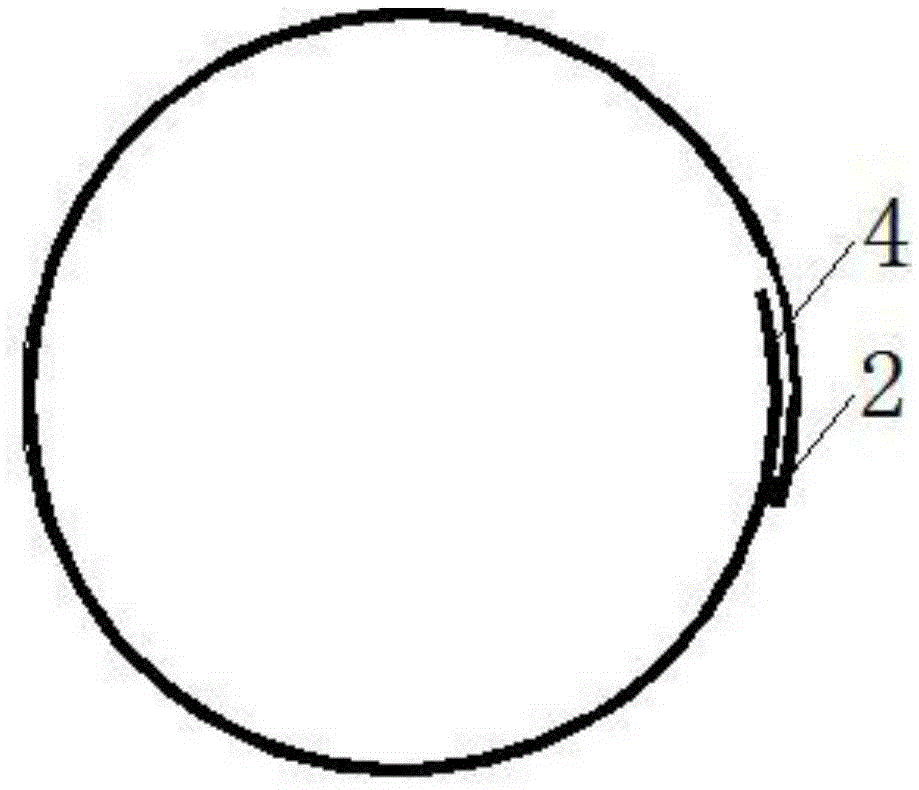

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a kind of integrated drip irrigation belt includes a capillary cavity 1 and a water inlet 4, an energy dissipation flow channel 5 and a water collection cavity 6 that are sequentially extruded and formed along the inner surface of the capillary cavity 1. The water chamber 6 is provided with a linear water outlet 7, and the capillary cavity 1 is provided with two parallel pressure seams 2, and the two pressure seams 2 are respectively located on both sides of the energy dissipation channel 5, the The outer wall of the water inlet 4, the outer wall of the energy dissipation channel 5, the outer wall of the water collection chamber 6 and the press ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com