Ion exchange process for thin glass chemical tempering and fused salt

A chemical tempering and ion exchange technology, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of affecting ion exchange, affecting the service life of molten salt, and reducing the transmittance of glass, and achieving a long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Wash the cut ordinary soda-lime-silica glass sheet with a thickness of 1.1mm and the alkali aluminosilicate glass with a thickness of 0.7mm (aluminum content is about 14%) with ultrasonic equipment, rinse with pure water and dry Standby, then put the clean original glass on the rack, put it together with the rack into the preheating furnace for preheating, the heating rate of the preheating furnace is 5°C per minute, and keep it warm for 30 minutes when it reaches 350°C , and then put the glass into molten salt for ion exchange. After the ion exchange, take out the glass and quickly put it into the annealing furnace to cool down. The temperature of the annealing furnace is 300°C; The glass is taken out of the furnace door, the molten salt attached to the glass surface is cleaned, dried and packaged.

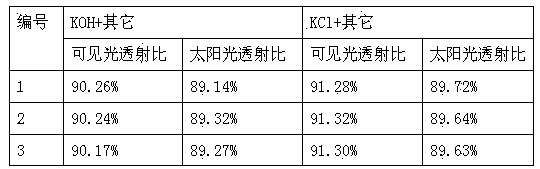

[0033] Fresh molten salt (without adding KSb(OH) 6 ) 3 parts were stored in 3 molten salt tanks, and the effect of ion exchange was compared with different con...

Embodiment 2

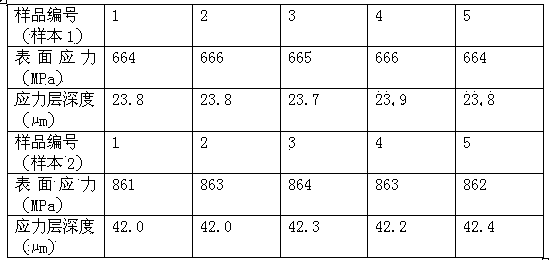

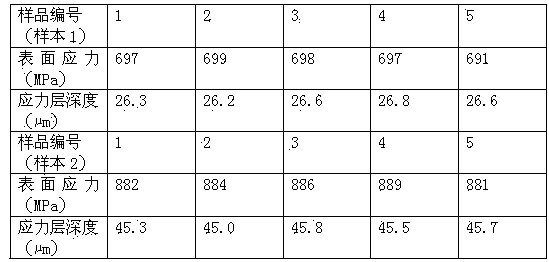

[0045] With the repeated use of the molten salt tank, when the Na of the molten salt in the three molten salt tanks + Concentrations of 0.15%, 0.18%, and 0.2% were taken from 3 molten salt tank products, and 5 pieces of ordinary soda-lime-silica glass (sample 1) and alkali aluminosilicate glass (sample 2) were taken out for surface stress and The test of the depth of the stress layer, the test results are as follows:

[0046]

[0047]

[0048]

[0049] It can be seen from the above table that when Na in molten salt + When the concentration is 0.15% and ~0.2%, the surface stress of the glass begins to show a downward trend. + Add 1 part by weight of KSb(OH) to a molten salt tank with a concentration of 0.15% 6 , in Na + Add 1.5 parts by weight of KSb(OH) to the molten salt tank with a concentration of 0.18% 6 , in Na + Add 2 parts by weight of KSb(OH) to a molten salt tank with a concentration of 0.2% 6 , use the up and down movement of the hanging basket to fully ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com