Water-based blocked polyisocyanate crosslinking agent of highly branched structure and preparation method thereof

A polyisocyanate, highly branched technology, applied in the field of polymer materials, can solve the problem that the effective active group does not reach the ideal level, and achieve the effect of increasing the content of active groups, wide application prospects, and increasing solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

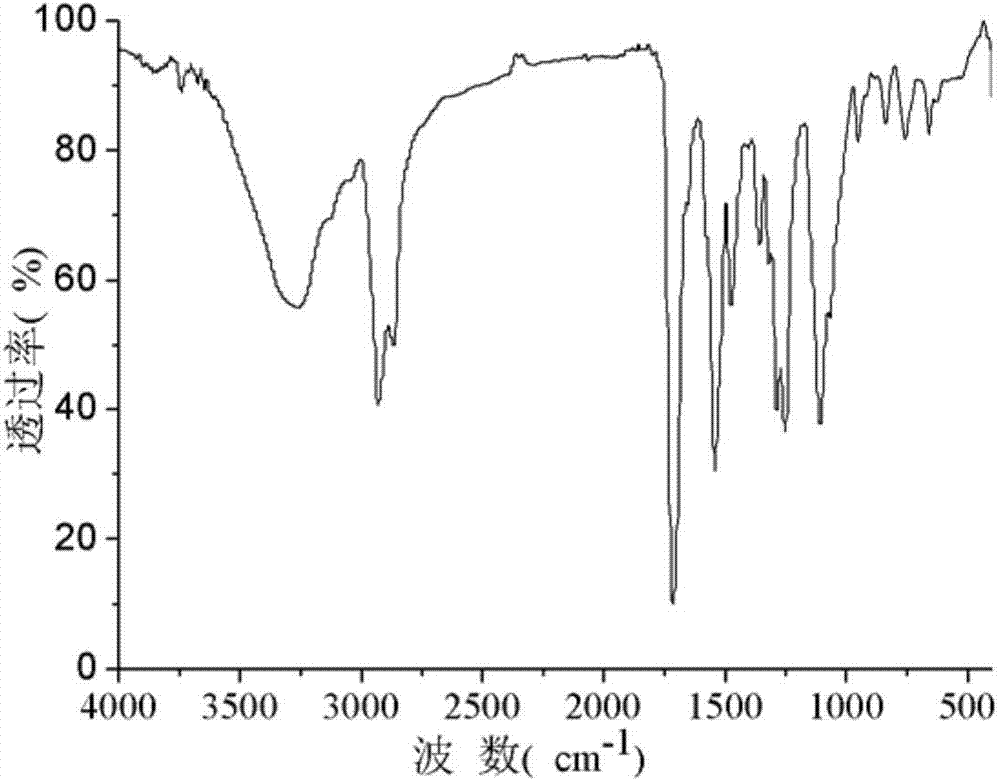

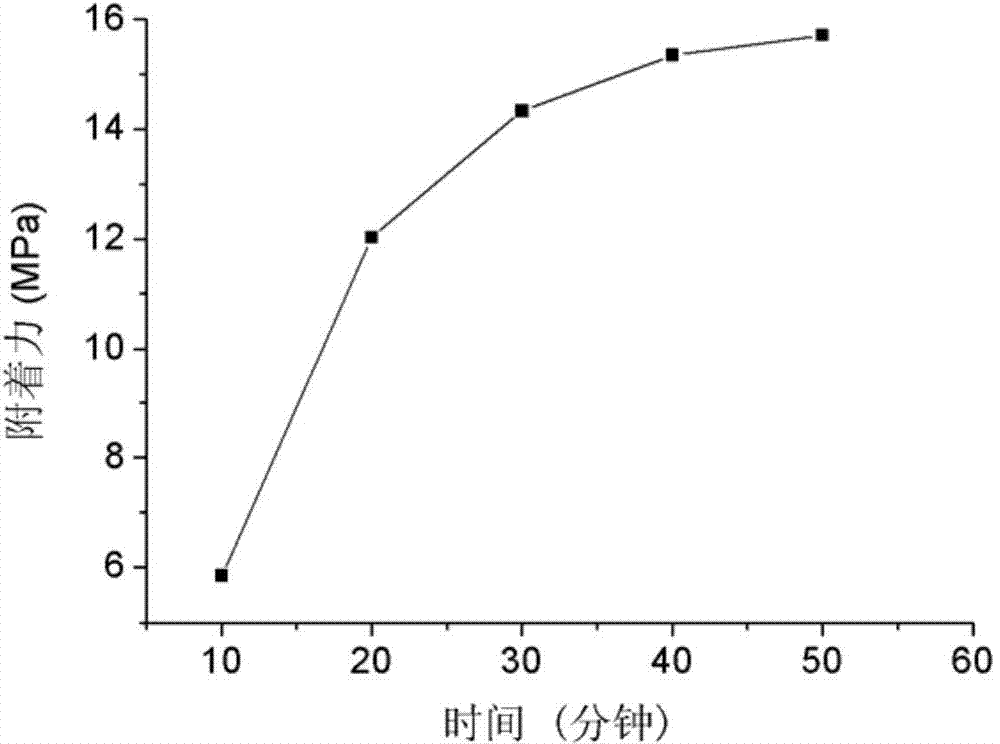

Embodiment 1

[0046] Under nitrogen protection and mechanical stirring, 18 parts of hexamethylene diisocyanate, 0.6% of dibutyltin dilaurate and 15 parts of methyl ethyl ketone were successively added to the four-necked flask, slowly rising to 65°C, and 1. Slowly add 5 parts of triethanolamine to the reaction system dropwise within one hour, and keep warm for 0.5 hours. The product at this time is used as the first step product; add 15 parts of triethanolamine and 12 parts of butanone in the four-necked flask, and then Slowly add the product of the first step within 1.5 hours, the reaction temperature is 60°C, and keep warm for 0.5 hours, and the product at this time is used as the product of the second step; add 35 parts of hexamethylene diisocyanate to the four-necked flask, Slowly add the second-step product dropwise within 1 hour, and keep warm at 60°C for 0.5 hours after the dropwise addition; keep the temperature constant, then add 4 parts of polyethylene glycol 600 dropwise to the sys...

Embodiment 2

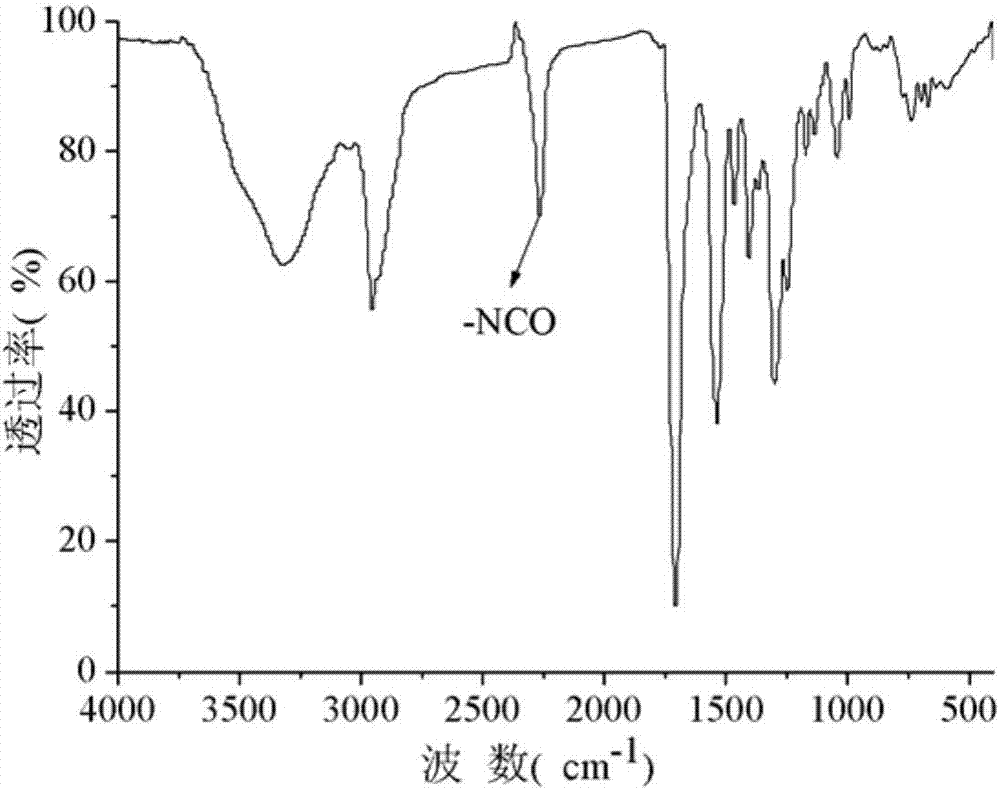

[0049] Under nitrogen protection and mechanical stirring, successively add 16 parts of isophorone diisocyanate, 0.5% of stannous octoate and 15 parts of acetone into the four-necked flask, slowly rise to 65 ° C, within 1. hour 4.5 parts of triethanolamine are slowly added dropwise to the reaction system, and the temperature is maintained for 0.5 hours. The product at this time is used as the product of the first step; The product of the first step, the reaction temperature is 65°C, heat preservation for 0.5 hours, the product at this time is used as the product of the second step; add 35 parts of isophorone diisocyanate to the four-necked flask, slowly add the second step within 1.5 hours For the second-step product, keep the temperature at 65°C for 0.5 hours after the dropwise addition; keep the temperature constant, then add 6.5 parts of polyethylene glycol 400 dropwise to the system within 0.5 hours, and keep the temperature for 0.5 hours; add 32.6 parts of 2-ethyl-4-methyl...

Embodiment 3

[0051] Under nitrogen protection and mechanical stirring, 20 parts of toluene diisocyanate, 0.5% of dibutyltin dilaurate and 10 parts of N-methyl-2-pyrrolidone were successively added to the four-necked flask, slowly rising to 60 ℃, 4 parts of triethanolamine are slowly added dropwise to the reaction system within 1. hour, and the temperature is maintained for 0.5 hours. The product at this time is taken as the first step product; 12 parts of triethanolamine and 10 parts of N Methyl-2-pyrrolidone, then slowly add the product of the first step dropwise within 1 hour, the reaction temperature is 60 ° C, keep warm for 0.5 hours, the product at this time is used as the product of the second step; add 40 parts of toluene to the four-necked flask In the diisocyanate, slowly add the second-step product dropwise within 1 hour, and keep the temperature at 60°C for 0.5 hour after the dropwise addition; keep the temperature constant, and then add 8 parts of polyethylene glycol 800 dropwis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com