A kind of preparation method of polyvinyl chloride pipe

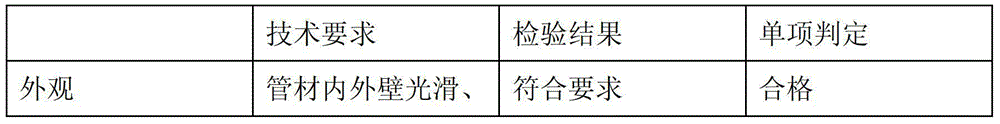

A polyvinyl chloride and pipe technology, which is applied in the field of preparation of polyvinyl chloride pipes, can solve the problems of high labor intensity, the use effect of auxiliary materials cannot achieve the expected purpose, and high power consumption, and achieves the effects of good strength, smooth appearance and stable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A preparation method of polyvinyl chloride pipe, comprising the following

[0014] step:

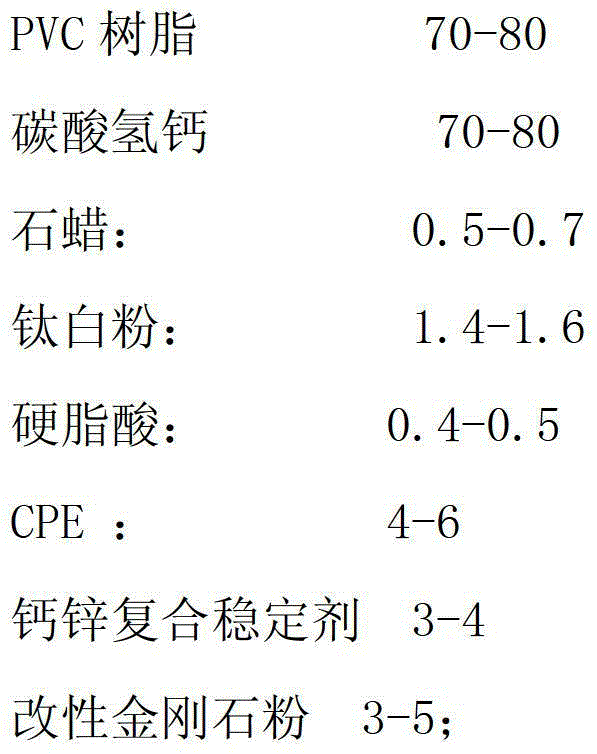

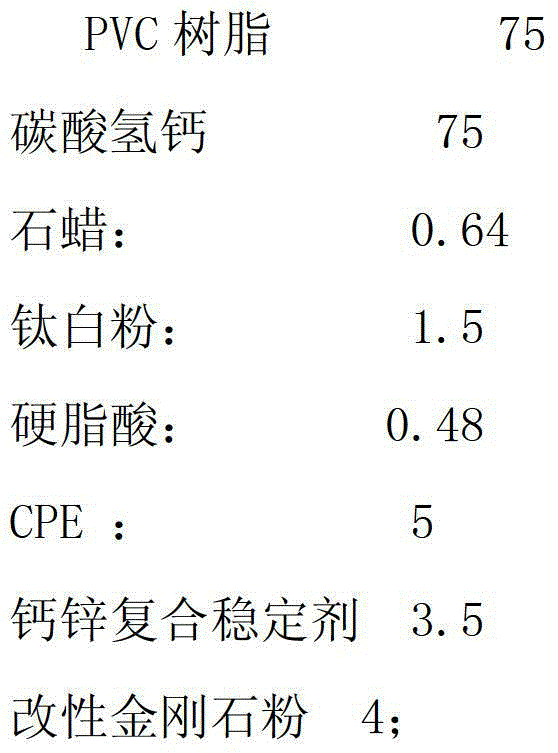

[0015] (1) Take each raw material by the weight g of the following composition raw materials:

[0016]

[0017] (2) Pour all raw materials except titanium dioxide and CPE into a stirring tank below 38°C and stir and mix at a speed of 55 rpm for 1 hour, then put it into a twin-screw extruder, knead at 150°C for 10 minutes, Mixing and granulation, the temperature is controlled at 160°C, and the finished product is obtained after the molding process;

[0018] The preparation method of the modified diamond powder is: calcining 10g of diamond powder at 550°C for 5 hours, adding 20g of attapulgite, 4g of iron powder, 2g of trioctyl trimellitate, 0.5g of glycerin, 0.5g of di Stir the methyl silicone oil at 40°C for 17 minutes, take it out, add 2g of aluminum hydroxide into an appropriate amount of water and grind evenly, add 2g of antioxidant 1076, 0.2g of graphene, stir evenly, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com