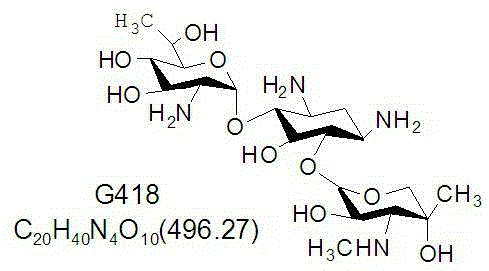

A kind of engineering bacteria producing g418 single component and its application

An engineering bacteria, single-component technology, applied in bacteria, recombinant DNA technology, microorganism-based methods, etc., can solve the problems of high price, difficult preparation of G418, complicated process, etc., achieve convenient extraction and purification, fill research gaps, fermentation Control simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

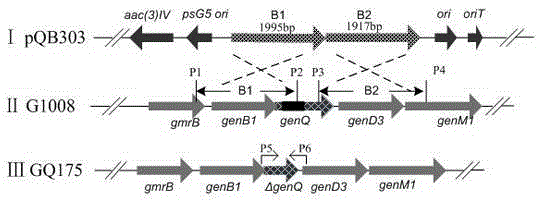

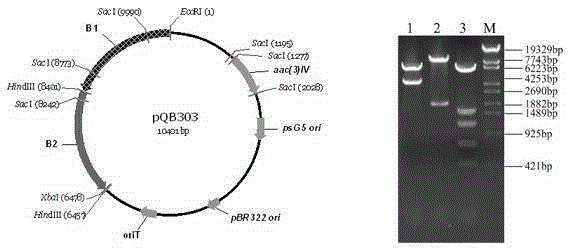

[0028] 1. Construction of homologous recombination plasmid pQB303

[0029] According to the gentamicin biosynthesis gene cluster (GenBankaccessionNo.: JQ975418, 44181bp) of Micromonas magenta published by Hong Wenrong et al. in 2012 and the gentamicin biosynthesis gene cluster of Micromonas aculeatus published by Piepersberg et al. GenBankAccessionNumberAJ628149), with gene gen Q Upstream and downstream sequences, design an in-frame knockout scheme ( figure 2 ). The two pairs of amplification exchange arm primers are PQ1 / PQ2 and PQ3 / PQ4 respectively. P1(5'-GAATTCAGGAGGTGCTCACCGACG-3', Eco RI), P2 (5'-AAGCTTAGAACCGGGTGTCCCTCG-3', Hin dIII); P3 (5'-AAGCTTTTCCGTTCGAAGGCGACC-3', Hin dIII), P4 (5'-TCTAGAAACGGCTCGGTGAACTCGTG-3', Xba I).

[0030]Using the genome of Micromonospora rubrum G1008 as a template, the PCR reaction system and reaction conditions are: 95°C for 5 minutes, 94°C for 1 minute, 67.5°C for 1 minute, 72°C for 1 minute, 72°C for 10 minutes, and 4°C for st...

Embodiment 2

[0038] Embodiment 2: Preparation of engineering bacteria GQ175 metabolites

[0039] 1. Fermentation of Engineering Bacteria GQ175 Strain

[0040] Seed medium: glucose 0.1%, corn starch 1.0%, corn flour 1.5%, peptone 0.2%, soybean meal 1.0%, KNO 3 0.05%, CaCO 3 0.5%, pH7.0.

[0041] Fermentation medium: corn starch 6.0%, corn flour 1.0%, peptone 0.4%, soybean cake powder 2.0%, KNO 3 0.01%, (NH 4 ) 2 SO 4 0.1%, CaCO 3 0.5%, amylase 0.025%, pH7.5.

example 1

[0042] Fermentation of Micromonospora magenta GQ175 obtained in Example 1 step 3. Before fermentation, isolate the single colony with rich sporulation by dilution plate method and transfer it to the slant medium, culture at 37°C for 10 days, excavate the block and inoculate it into the seed medium (50mL / 250mL Erlenmeyer flask), and culture on a shaker at 37°C 36h (rotating speed: 250rpm), when submerged culture enters the logarithmic growth phase, transfer 10% of the inoculum to the fermentation medium (capacity: 50mL / 250mL Erlenmeyer flask), and ferment on a shaking table at 37°C for 120h (rotating speed: 250rpm).

[0043] 20,000 liters fermenter production, stirring speed 180 rpm, ventilation volume 1: 0.5~1.0(M 3 / M 3 min), culture medium, culture temperature, inoculum ratio, fermentation time, etc., similar to shake flask fermentation.

[0044] 2. Extraction and purification of metabolites

[0045] A. Rough extraction

[0046] After the fermentation broth is diluted an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com