Method utilizing hydrogen-producing acetogens and electricigens to enhance biological hydrogen production efficiency

A technology of hydrogen-producing acetogenic bacteria and biological hydrogen production, applied in the direction of fermentation, etc., can solve the problems of development limitation of fermentation hydrogen production, unstable operation of dark fermentation reactor, incomplete conversion of substrate, etc., and achieve low price and high hydrogen production Efficiency improvement and cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The enrichment reactor for hydrogen-producing acetogenic bacteria is carried out by inoculating the aerobic activated sludge of the secondary sedimentation tank with the ABR reactor; the enrichment of electrogenic bacteria is carried out through the MFC reactor, and then introduced into the microbial electrolysis cell (MEC), Finally, the effluent of the ABR reactor was used as the substrate of MEC to realize the combined hydrogen production of hydrogen-producing acetogenic bacteria and electrogenic bacteria.

[0015] 1. Enrichment of hydrogen-producing acetogenic bacteria and electrogenic bacteria

[0016] Preparation of ABR feed water: add a certain amount of carbohydrates to tap water, and add 5.73g NH at the same time 4 Cl, 1.32g KH 2 PO 4 , 30g NaHCO 3 , while adding 1ml / L trace element solution to prepare organic wastewater; the final control concentration of chemical oxygen demand (COD) of organic wastewater is 4600mg / L, pH=7.10.

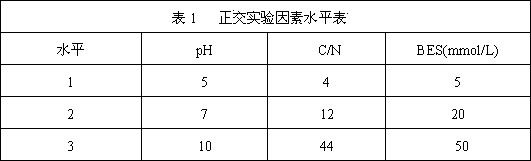

[0017] Preparation of MEC st...

Embodiment 2

[0030]Coupling hydrogen-producing acetogenic bacteria and electrogenic bacteria to achieve cascade organic matter degradation and deep hydrogen production. Among them, hydrogen-producing acetogenic bacteria and electrogenic bacteria were respectively inoculated into the same anaerobic reactor ABR with pure strains. The aerobic activated sludge of the secondary sedimentation tank was inoculated into the first chamber of the ABR reactor to degrade the organic matter initially, and the pure hydrogen-producing acetogenic bacteria were inoculated in the second chamber by using the plug-flow characteristics of the ABR. The products generated in the first compartment are degraded into H 2 ; Finally, inoculate the pure-bred electrogenic bacteria in the third compartment, and use the cathode and anode connected in the compartment, under the catalysis of the additional voltage, further degrade and convert the terminal substrate volatile fatty acid produced in the second compartment into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com