Peanut peptide preparation method for enzymatically decomposing thermal-crushed peanut meal step by step with double neutral protease

A technology of neutral protease and hot-pressed peanut meal, which is applied in fermentation and other directions, can solve the problems of limited utilization of hot-pressed peanut meal, low yield of short peptide and low degree of hydrolysis, affecting function and physiological activity, etc., and achieves short peptide yield And the effect of high degree of hydrolysis, short preparation time and strong functional activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

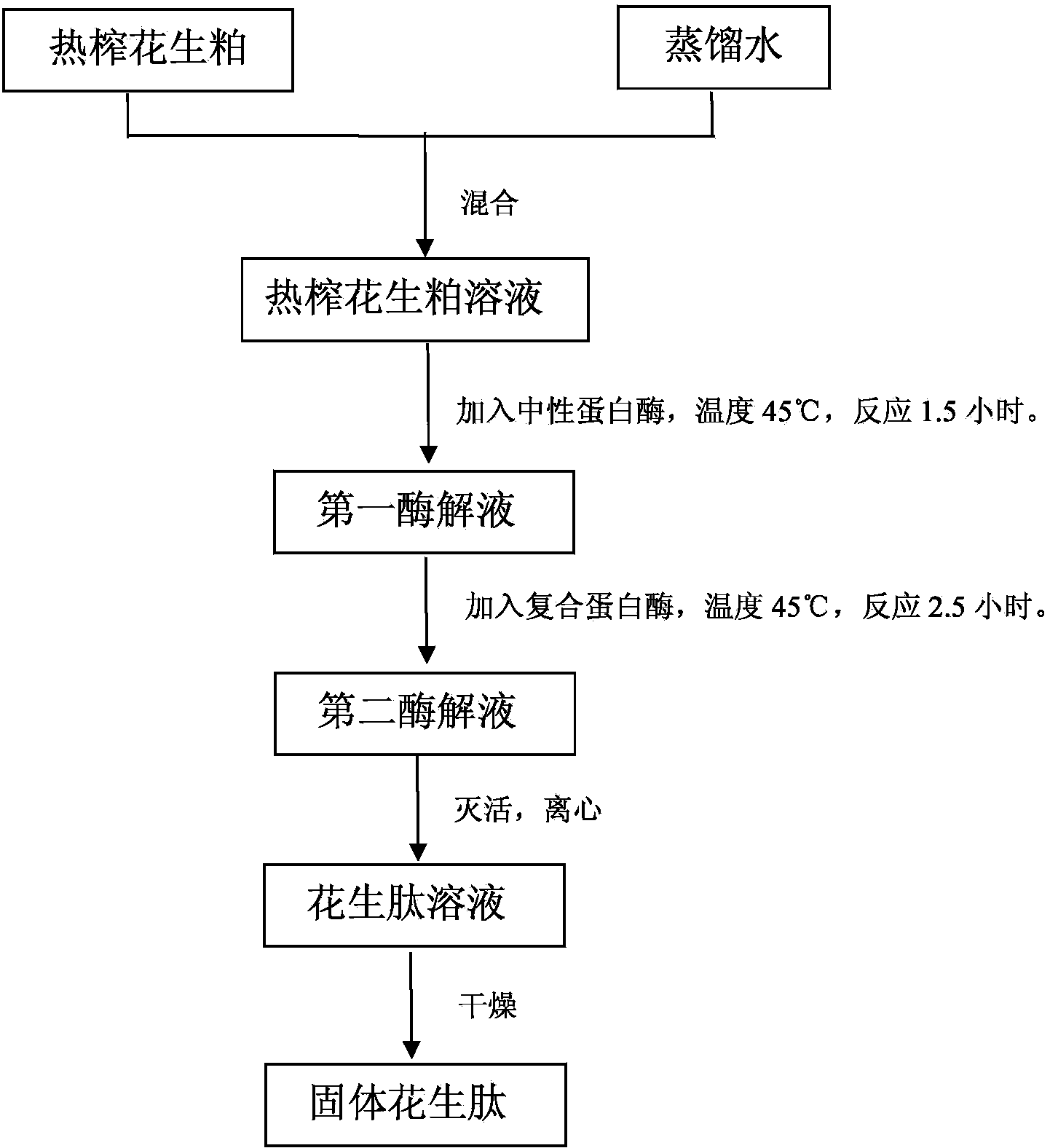

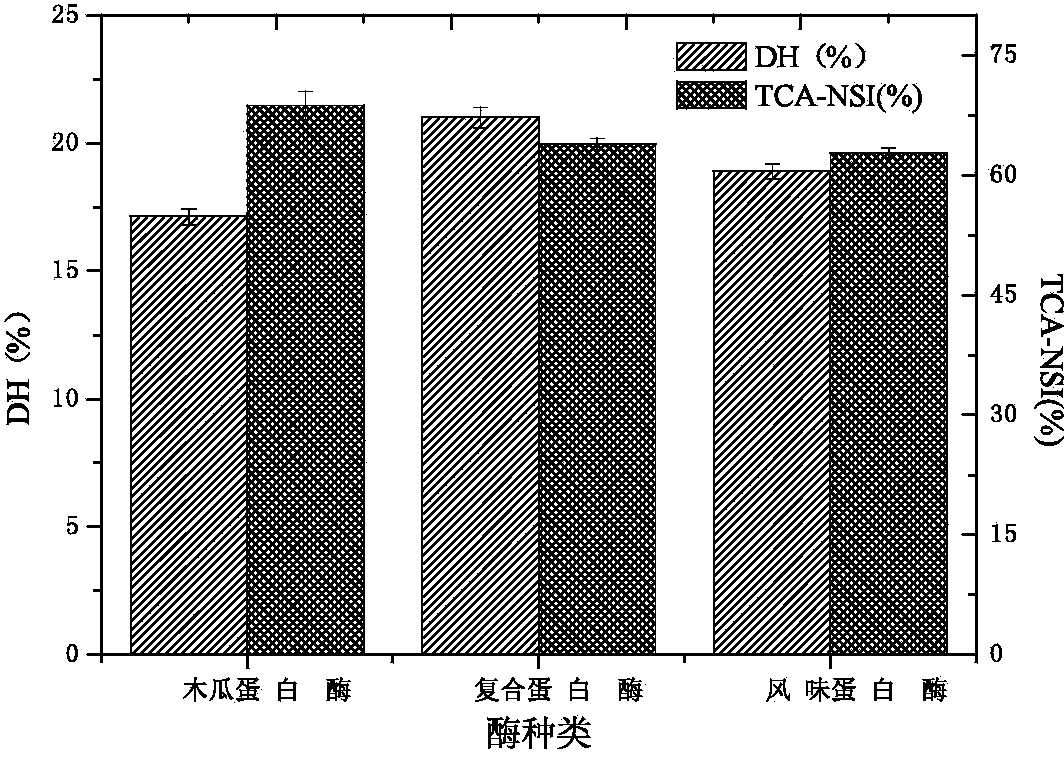

[0054] Embodiment 1, investigate the impact of different protease complexes on the degree of hydrolysis and the yield of short peptides

[0055] The first step: take hot-pressed peanut meal, add distilled water to dissolve it, and obtain a hot-pressed peanut meal solution with a mass concentration of 14%. This process ensures that it is fully in contact with protease, which is conducive to the progress of enzymatic hydrolysis;

[0056] Step 2: After the first step is completed, take out the hot-pressed peanut meal solution, raise the temperature to 45°C and add neutral protease. Medium reaction 1.5h;

[0057] Step 3: After the reaction in the second step, add complex protease in an amount of 374U / g peanut protein, mix well, and continue to react in a constant temperature water bath shaker at 45°C for 1.5h;

[0058] Step 4: Take it out after the reaction in the third step, put it in a constant temperature water bath at 90°C for 10 minutes to inactivate neutral protease and com...

Embodiment 2

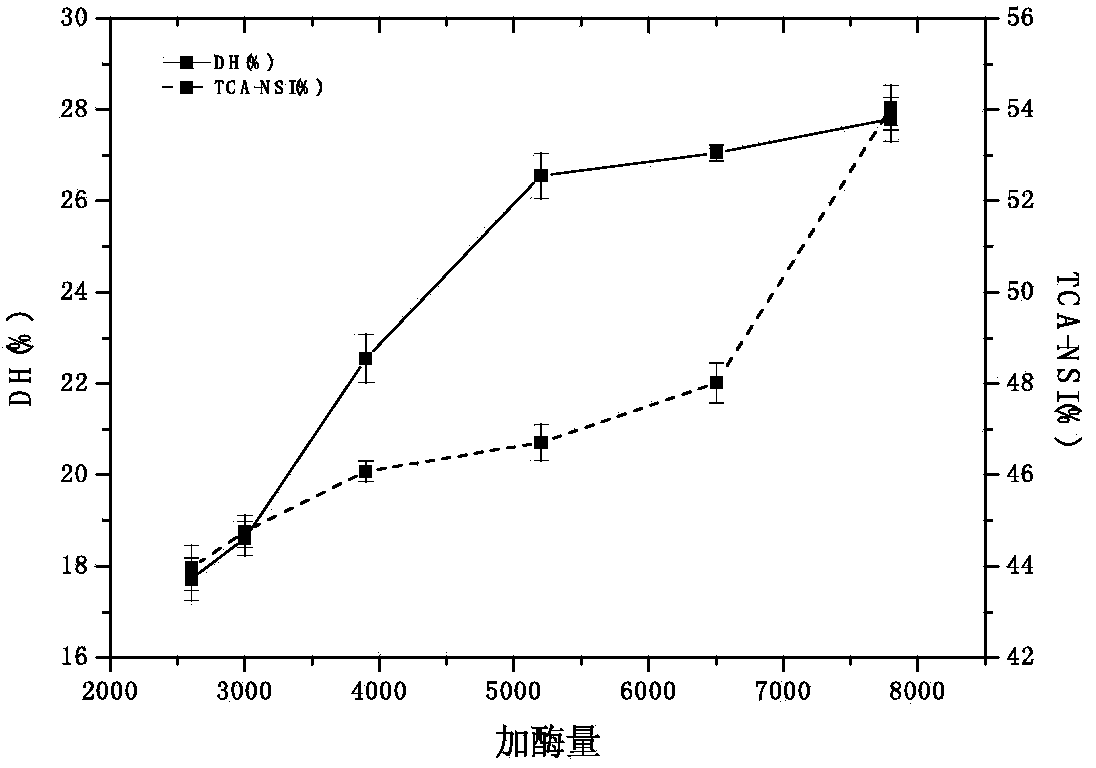

[0064] Embodiment 2, investigate the impact of compound protease dosage on degree of hydrolysis and short peptide yield

[0065] The first step: take hot-pressed peanut meal, add distilled water to dissolve it, and obtain a hot-pressed peanut meal solution with a mass concentration of 14%. This process ensures that it is fully in contact with protease, which is conducive to the progress of enzymatic hydrolysis;

[0066] Step 2: After the first step is completed, take out the hot-pressed peanut meal solution, raise the temperature to 45°C, add neutral protease, the amount of addition is 5200U / g peanut protein, and react in a constant temperature water bath shaker at 45°C for 1.5h:

[0067] Step 3: After the reaction in the second step, add different amounts of complex protease, the amount added is 124-624U / g peanut protein, mix well, and continue to react in a constant temperature water bath shaker at 45°C for 2.5h;

[0068] Step 4: Take it out after the reaction in the third s...

Embodiment 3

[0070] Example 3: Investigating the effects of different enzymatic hydrolysis temperatures on the degree of hydrolysis and the yield of short peptides

[0071] Step 1: Take hot-pressed peanut meal, add distilled water to dissolve it, and obtain a hot-pressed peanut meal solution with a mass concentration of 14%. This process ensures that it is fully in contact with protease, which is beneficial to the enzymatic hydrolysis reaction;

[0072] Step 2: Adjust the temperature to 45°C, the suitable temperature for neutral protease, add neutral protease in an amount of 5200U / g peanut protein, and react in a constant temperature water bath shaker at 45°C for 1.5h;

[0073] Step 3: After the reaction in the second step, add complex protease in an amount of 374U / g peanut protein, mix well, and continue to react in a constant temperature water bath shaker at 45°C for 2.5h;

[0074] Step 4: After the reaction in the third step, keep it in a constant temperature water bath at 90°C for 10 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of hydrolysis | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com