Color water-absorbing interleaving paper production process

A manufacturing process and backing paper technology, which is applied in special paper, paper, papermaking, etc., can solve the problems of expensive imported colored water-absorbing backing paper, the inability to quickly spread liquid around, and failure to meet market demand, etc., to increase wet tensile strength Strength, maintaining flatness, and increasing the effect of bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

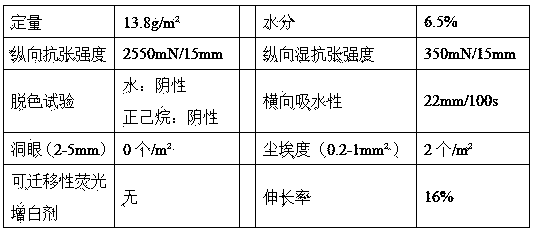

Embodiment 1

[0024] A manufacturing process of colored water-absorbent backing paper, including wood pulp disintegration, beating, pulping, color matching, screening and purification, net forming, vacuum dehydration, press dehydration, drying cylinder drying, scraper wrinkling, coiling, rewinding and slitting , Packaging made finished products. The detailed steps are as follows:

[0025] Wood pulp disintegration: First, mix the long-fiber wood pulp with a fiber length of 2.5mm and the short-fiber wood pulp with a fiber length of 0.7mm according to the ratio of 75:25 by weight, and add a concentration of 12.5%. The amount of paper is 0.35kg of fiber modifying enzyme, and then the fiber is disintegrated by a hydropulper.

[0026] Beating: Then the fibers are beaten through a beater with a beating degree of 23oSR, and finally the beating concentration is controlled at 3.2% to obtain pulp.

[0027] Pulping: Add biopolymer to the prepared pulp at a speed of 3000L / min and stir until uniform. A...

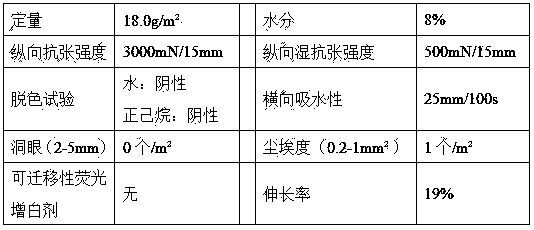

Embodiment 2

[0039] A manufacturing process of colored water-absorbent backing paper, including wood pulp disintegration, beating, pulping, color matching, screening and purification, net forming, vacuum dehydration, press dehydration, drying cylinder drying, scraper wrinkling, coiling, rewinding and slitting , Packaging made finished products. The detailed steps are as follows:

[0040] Wood pulp disintegration: First, mix the long-fiber wood pulp with a fiber length of 2.6mm and the short-fiber wood pulp with a fiber length of 0.8mm according to the ratio of 78:22 by weight, and add a concentration of 12%. The paper weight is 0.4kg of fiber modifying enzymes, and then the fibers are broken down by a hydropulper.

[0041] Beating: Then the fibers are beaten through a beater with a beating degree of 25oSR, and finally the beating concentration is controlled at 3.0% to obtain pulp.

[0042] Pulping: Add biopolymer to the prepared pulp at a speed of 3000L / min and stir until uniform. After ...

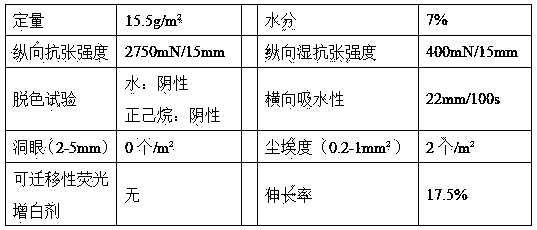

Embodiment 3

[0055] A manufacturing process of colored water-absorbent backing paper, including wood pulp disintegration, beating, pulping, color matching, screening and purification, net forming, vacuum dehydration, press dehydration, drying cylinder drying, scraper wrinkling, coiling, rewinding and slitting , Packaging made finished products. The detailed steps are as follows:

[0056] Wood pulp disintegration: First, mix the long-fiber wood pulp with a fiber length of 2.7mm and the short-fiber wood pulp with a fiber length of 0.9mm according to the ratio of 80:20 by weight, and add a concentration of 13%. 0.5kg of fiber-modifying enzyme was used, and then the fiber was disintegrated by a hydropulper.

[0057] Beating: Then the fibers are beaten through a beater with a beating degree of 26oSR, and finally the beating concentration is controlled at 3.5% to obtain pulp.

[0058] Pulping: Add biopolymer to the prepared pulp at a speed of 3000L / min and stir until uniform. After an interval...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com