A Loading System for Large-Scale Model Test of Subgrade Slope Support and Retaining Structure

A technology of retaining structure and loading system, which is applied in the test of foundation structure, foundation structure engineering, construction, etc., and can solve the problem of large-scale model test research that is difficult to reflect the reality, the size and distribution of structures are not clear, and the retaining structure Difficulties and other problems, to achieve the effect of small environmental impact, clear size and distribution form, and good displacement control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

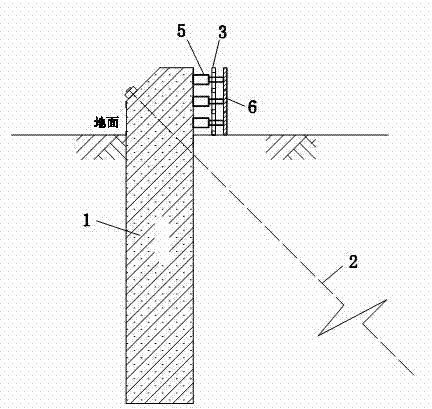

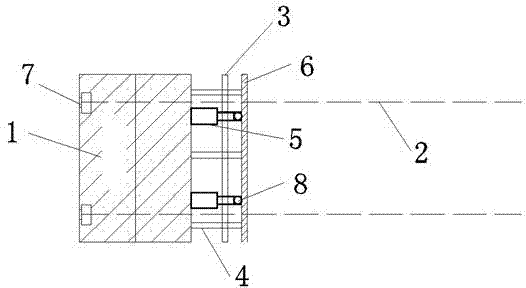

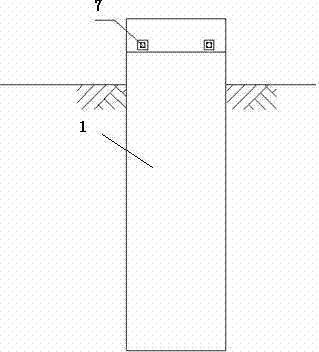

[0017] Such as Figure 1-3 As shown, the horizontal loading system of the present invention is composed of a reaction wall 1, a servo loading cylinder 5, a loading plate 6, a guide rod 4, and an anchor cable 2. The reaction wall is embedded in the foundation (the depth of the foundation is determined according to the relevant calculation results). Two anchor cables 2 are installed on the top for reinforcement, and multiple servo loading cylinders are installed on the ground part of the reaction wall. One end of the servo loading cylinder is connected to the loading plate, and there is a guide rod between the reaction wall and the loading plate. It is connected with the loading plate through a ball joint, and the servo loading cylinder is fixed by the servo loading cylinder support 3 .

[0018] The reaction wall is divided into a cantilever section above the ground and an embedded section of the underground part. The reaction wall is a reinforced concrete structure and provides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com