Method for casting ledges of middle troughs of scraper conveyer by V (vacuum) method

A technology of scraper conveyor and trough side, which is applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of complex structure of the middle trough, inability to cast and shape, and uneven thickness, so as to reduce deformation and achieve accurate dimensions , the effect of less harmful gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is described in further detail below by a best embodiment:

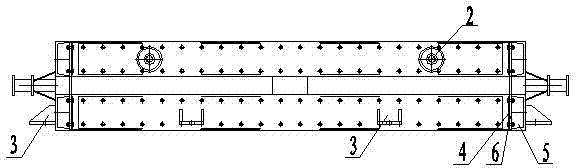

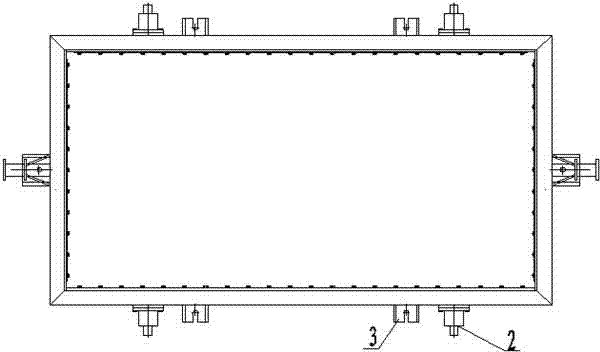

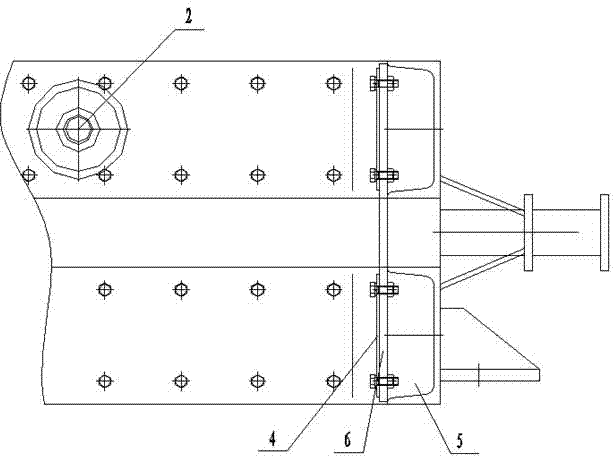

[0046] A method for casting the side of a groove in the middle part of a scraper conveyor using the V method, including placing a pattern, covering the pattern with a film and heating and forming, placing a sand box, adding sand and vibrating, covering the film, removing the mold, closing the box, pouring, Shakeout process.

[0047] The material of the side of the middle groove in this embodiment is ZG30MnSiCrNi, wherein the weight percentage of Si is controlled at 0.6-0.8%, the weight percentage of Mn is controlled at 1.1-1.4%, and the weight percentage of Ni is controlled at 0.1-0.2% , the weight percentage of Cr is controlled at 0.2-0.3%, and other components can be controlled according to the national standard; the casting temperature is 1580-1600 °C.

[0048] The sand box is in the form of a combination of upper and lower sand boxes, and 10mm thick steel plates are continuously weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com