Vapor-liquid-solid spiral-flow type stabilized-pressure mixing conveyor

A swirling, gas-liquid-solid technology, applied in the direction of gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems such as increased geometric discontinuity of the cylinder, equipment damage, and increased opening ratio. Achieve the effects of improving the overall structural stress, improving structural stability, and reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

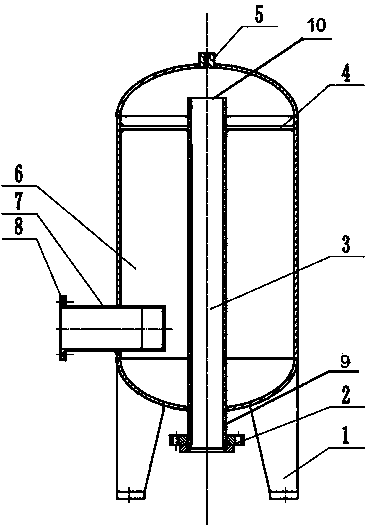

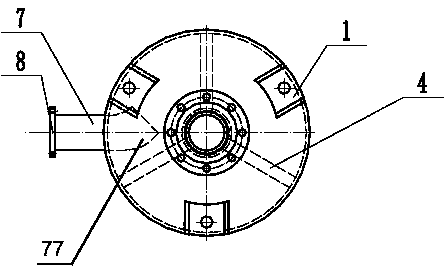

[0020] The gas-liquid-solid swirling flow stabilized pressure mixer includes a tank body 6, an oil inlet pipe 7 and an oil outlet pipe 9. The oil inlet pipe is connected orthogonally to the tank body. The end 77 of the oil inlet pipe is bent along the circumferential direction of the tank body, and the oil outlet is located at At the bottom of the tank, the inner end of the oil outlet pipe extends upwards to form an oil inlet 10. The height of the extension pipe 3 in the tank of the oil outlet pipe is higher than that of the oil inlet pipe 7. There is a reinforcement between the extension pipe in the tank of the oil outlet pipe and the tank body. tendon 4.

[0021] A pressure gauge communicated with the inside of the tank is provided at the top of the tank, and the pressure gauge is connected with the inside of the tank through a connecting pipe 5 on the top of the tank.

[0022] The outer ends of the inlet and outlet pipes are provided with connecting flanges.

[0023] When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com