LED lamp tube

A technology of LED light tubes and LED light strips, which is applied in cooling/heating devices of lighting devices, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., and can solve the problem of strong light absorption and poor light transmission effect of the plastic pipe on the upper shell , poor heat dissipation and other problems, to solve glare and spot light, improve light output efficiency, and reduce the effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

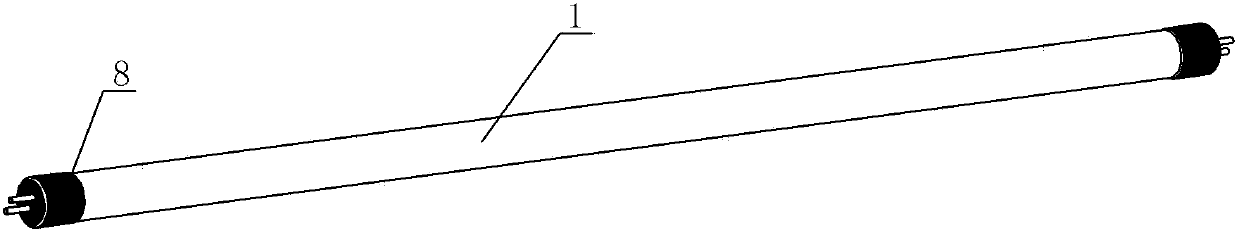

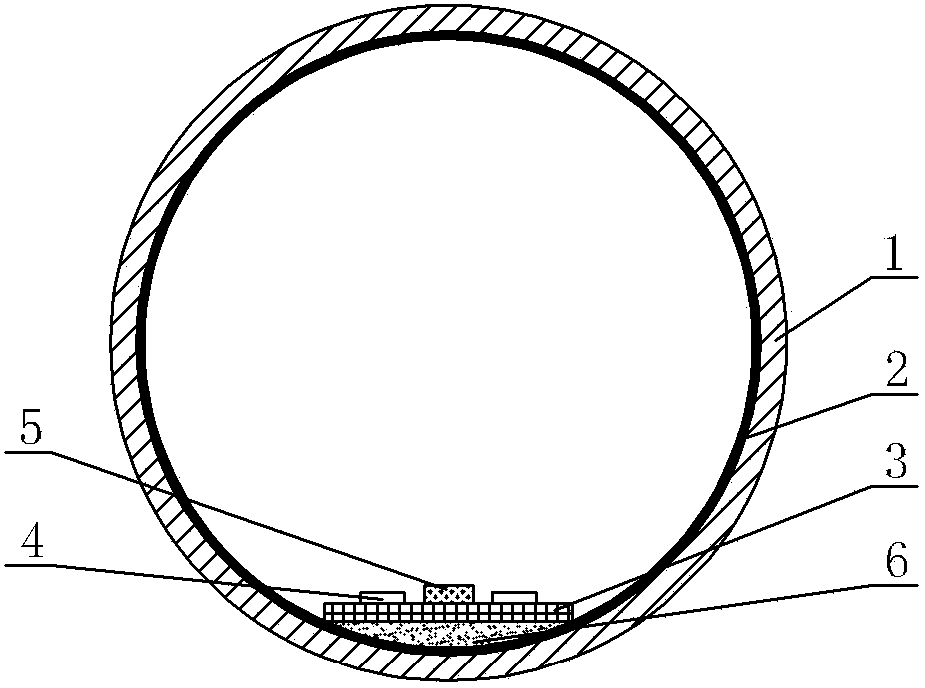

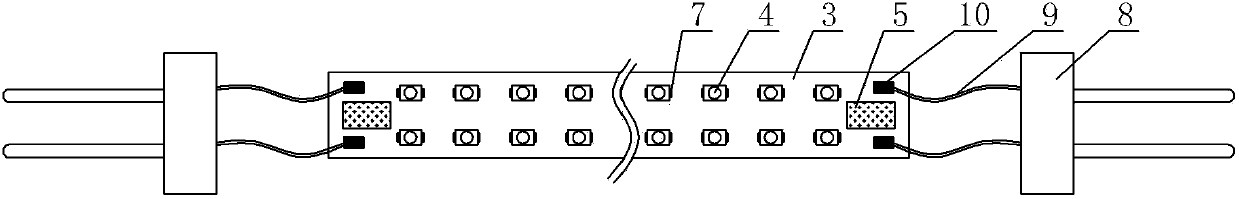

[0025] see Figure 1-Figure 3 , the LED lamp tube includes a glass tube 1, a lamp holder 8 arranged at both ends of the tube, and an LED lamp bar arranged inside it, the inner wall of the glass tube 1 is coated with a light-enhancing heat dissipation film 2, and the LED lamp bar is passed through a high thermal conductivity adhesive Glue 6 is bonded and fixed on the inner wall of glass tube 1 . The light-enhancing and heat-dissipating film 2 is an aluminum-plated layer, or a frosted heat-conducting and light-enhancing adhesive layer, or a nano-adhesive layer that can increase light and dissipate heat. The LED light bar includes a base plate 3 bonded and fixed on the glass tube 1. Several LED light sources 4 connected in parallel (or in series) are welded on the base plate 3. The LED light source 4 is a light-emitting diode, and its pin 7 is connected through tin Wire or solder paste is soldered on the pads 10 of the substrate 3 . The LED light bar is also provided with a dri...

no. 2 example

[0030] see Figure 4 The main difference between this LED light tube and the first embodiment is that the substrate 3 of the LED light bar is packaged with an integrated light source composed of several LED chips 11 connected in parallel (or in series). The LED chip 11 is electrically connected to the energized pad 10 of the substrate 3 through a metal wire 13, and the light-emitting surface 12 of the substrate 3 corresponding to the LED chip 11 is filled with a phosphor adhesive layer 14, and the phosphor adhesive layer 14 covers the LED chip 11. and wrapping the metal wire 13, the driving power supply module 5 can supply power to the LED chip 11 to make the LED chip 11 emit light. Other unmentioned parts are the same as the first embodiment and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com