Odor-free drying device

A drying device, odorless technology, applied in drying gas arrangement, heating device, drying solid materials, etc., can solve the problem of inability to completely eliminate the odor of exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

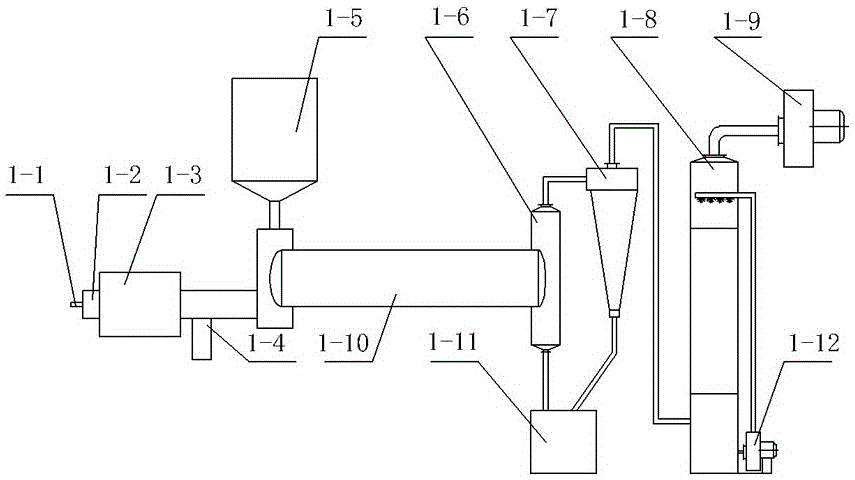

[0017] The present invention is an odorless drying device, which includes a regenerative hot air stove 2 and a dryer 10 .

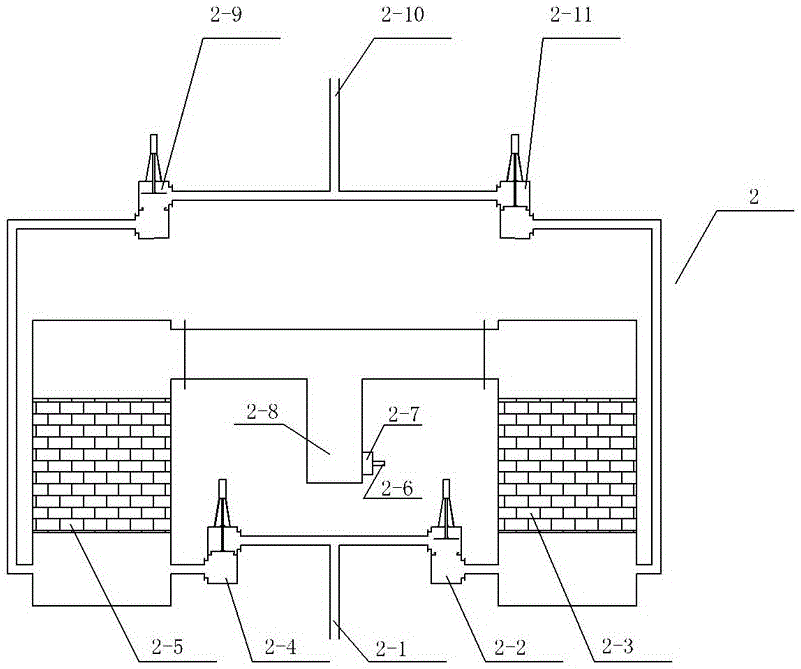

[0018] The regenerative hot blast stove 2 includes two regenerators 2-3, 2-5 connected to each other controlled by four air shut-off valves, wherein the two air shut-off valves 2-2, 2-4 control the regenerative hot stove. The air inlet of the hot blast stove, the other two air cut-off valves 2-9, 2-11 control the air outlet of the regenerative hot blast stove, the upper parts of the two regenerators 2-3, 2-5 are connected, and the hot blast stove is connected 2-8, burner 2-7, combustion air inlet 2-6, such as figure 2 As shown, heat storage material is installed in the heat storage chamber, and the function of the heat storage chamber is to alternately absorb heat from hot air or transfer the absorbed heat to the cold air flowing through it.

[0019] Such as figure 2 , 4 As shown, when the air cut-off valve 2-2 is opened, 2-9 is opened, 2-4 is closed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com