Spiral wound tube heat exchanger and variable flow spiral tube cooling device

A tubular heat exchanger, spiral winding technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc. The improvement of the heat transfer effect of the hot surface is not obvious, so as to achieve stable operation, reduce the possibility and fouling tendency, and solve the effect of the large difference in the convective heat transfer coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 Spiral wound tube heat exchanger

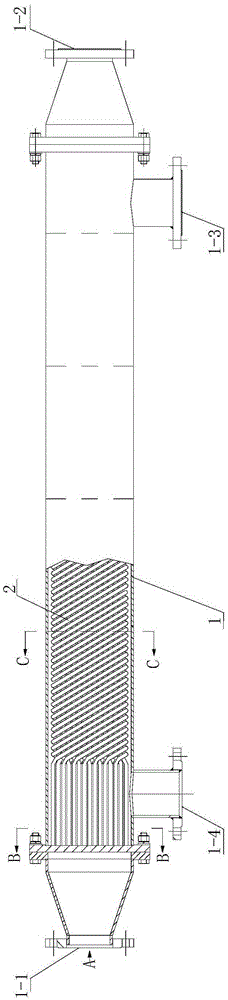

[0026] Picture 1-1 It shows the structure of a preferred embodiment of a helically wound tube heat exchanger of the present invention, which is used for water cooling of lubricating oil and other fluids.

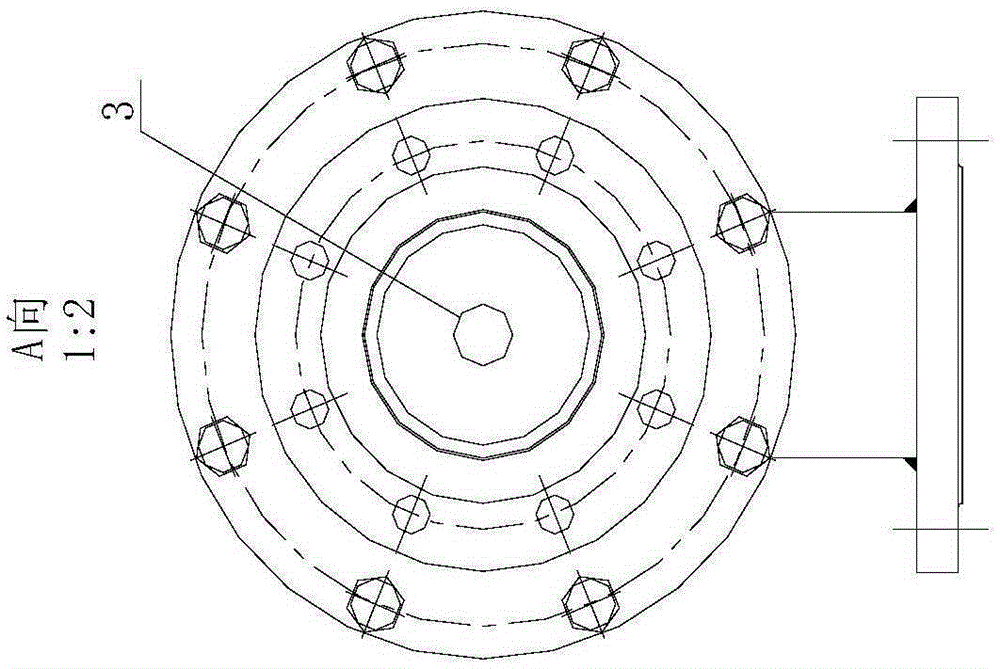

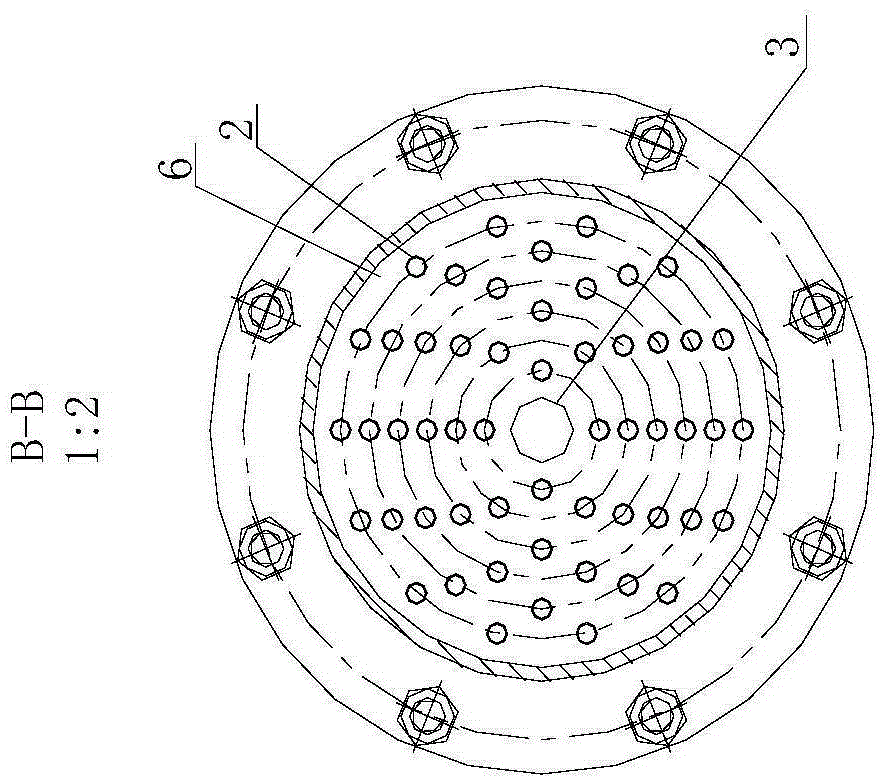

[0027] Such as Picture 1-1 As shown, the spiral wound tube heat exchanger includes a shell 1 and a spiral tube bundle installed on the tube sheet 6 at both ends of the shell, and the two ends of the shell 1 are provided with a tube inlet 1-1 and a tube outlet 1 -2, there are shell-side inlets 1-3 and shell-side outlets 1-4 on the side wall of the shell 1, and the two ends of the spiral tube bundle composed of multiple spiral tubes 2 are installed on the tube sheets 6 at both ends of the heat exchanger.

[0028] Structural bonding of helical tube bundles Picture 1-1 and Figure 1-4 As shown, the spiral tube bundle is composed of six layers of spiral tubes 2 concentrically wound into a spiral shape, and each layer of s...

Embodiment 2

[0046] Embodiment 2 variable flow helical tube reverse winding cooling device

[0047] Such as figure 2 As shown, it is a variable flow helical tube reverse winding cooling device, and the helical tube heat exchanger adopts the structure of Embodiment 1.

[0048] The cooling device includes a spiral tube heat exchanger, a temperature sensor, a control system, a variable frequency motor, and a pump driven by the variable frequency motor. The temperature sensor is arranged on the tube side outlet pipeline of the spiral wound tube heat exchanger. The output end is connected to the input end of the control system, the input end of the frequency conversion motor is connected to the output end of the control system, and the outlet of the pump is connected to the shell-side inlet of the spiral wound tube heat exchanger.

[0049] The temperature at the outlet of the coiled tube heat exchanger is measured by a temperature sensor, which uploads the temperature to the control system. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com