Rapid detection evaluation method of roller surface layer grain size

A technology of grain size and roll, applied in the direction of particle size analysis, measuring device, particle and sedimentation analysis, etc., to achieve the effect of improving detection speed, simplifying detection process, and accurate and objective roll quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The rapid detection and evaluation method of roll surface grain size of the present invention comprises the steps:

[0035] Step 1. Use a cleaning agent to clean the inspected area of the surface-ground roll to remove surface grease and attachments and wipe it clean;

[0036] Step 2, preparing a surface wave sensitivity test block with right-angled edges, the surface and material of the sensitivity test block are similar to the surface and material of the tested roll;

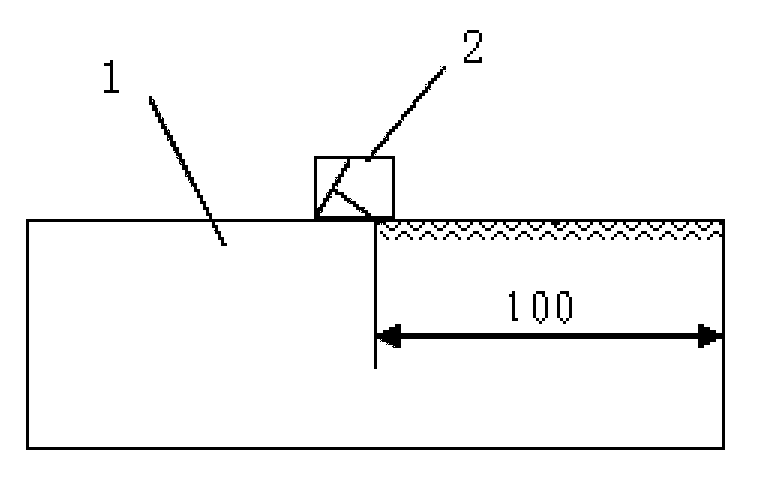

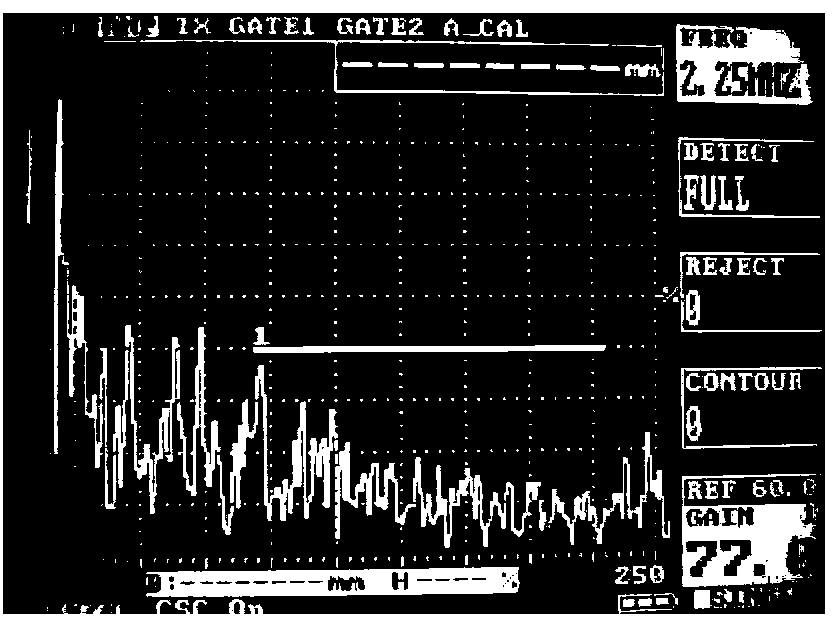

[0037] Step 3. Use an ultrasonic flaw detector, select a surface wave probe with a detection frequency of 2MHz, medical glycerin or engine oil as the probe coupling agent, and use the surface wave test block end edge method to adjust the detection sensitivity of the ultrasonic flaw detector, such as figure 1 As shown, the surface wave probe 2 is placed at a position 100 mm away from the right-angled edge of the test block 1, and the reflected echo of the right-angled edge of the test block is adjusted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com