Copper indium gallium diselenide thin film cell co-evaporation linear source array configuration

A thin-film battery, copper indium gallium selenide technology, applied in vacuum evaporation plating, circuit, photovoltaic power generation, etc., can solve the problems of low flexibility of coating, inability to realize matching process, and inability to realize flexible coating process, etc. To achieve the effect of improving the adjustment flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

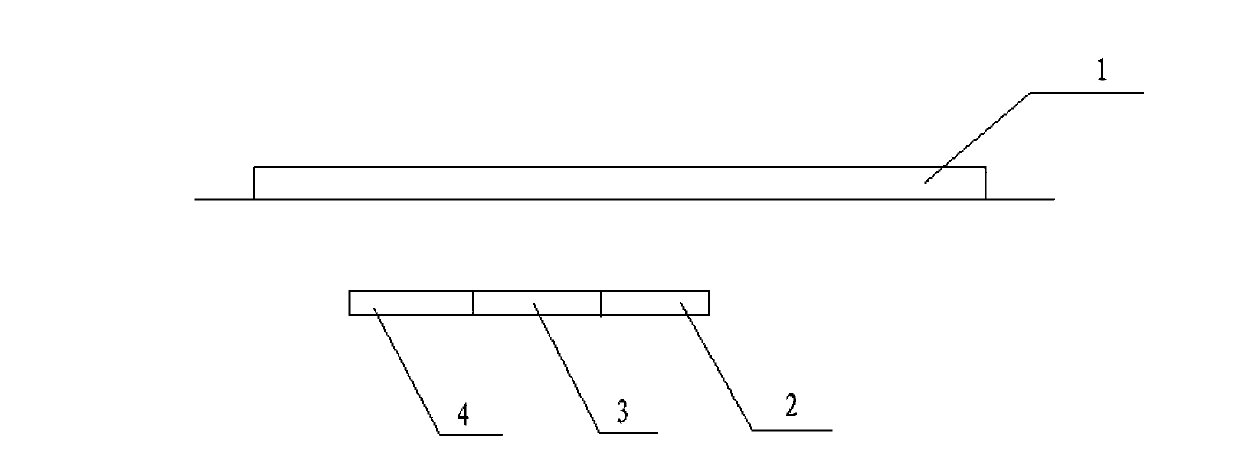

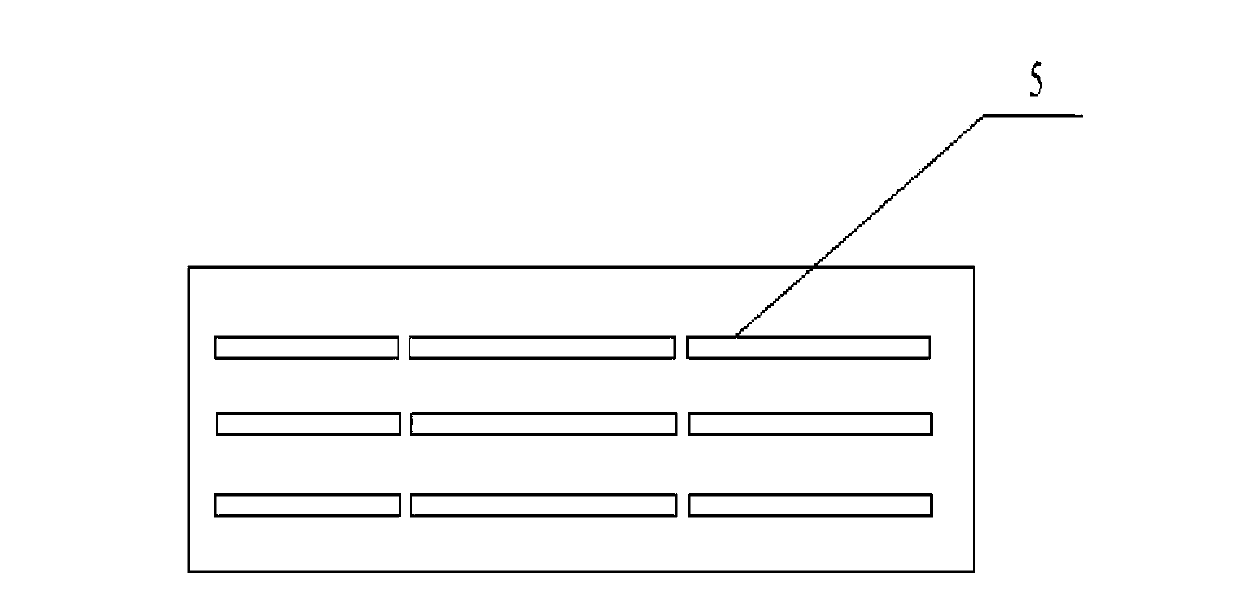

[0024] An arrangement of co-evaporation linear source arrays for copper indium gallium selenide thin film batteries, such as figure 1 , figure 2 As shown, it includes a glass substrate 1 and linear evaporation sources 2, 3, and 4. The linear evaporation sources 2, 3, and 4 containing different raw materials are arranged longitudinally along the moving direction of the glass substrate 1 to form a linear evaporation source column. The linear evaporation source column is One column is located directly below the glass substrate 1 . The linear evaporation sources 2, 3 and 4 are cuboids. The linear evaporation sources 2, 3, 4 are provided with three parallel slit-shaped evaporation belts 5. Along the lower sides of the two sides of the glass substrate 1 there are corresponding evaporation zones 5 . The three parallel slit-shaped evaporation zones 5 correspond to three separate heating sources. The raw material in each linear evaporation source constituting the linear evaporatio...

Embodiment 2

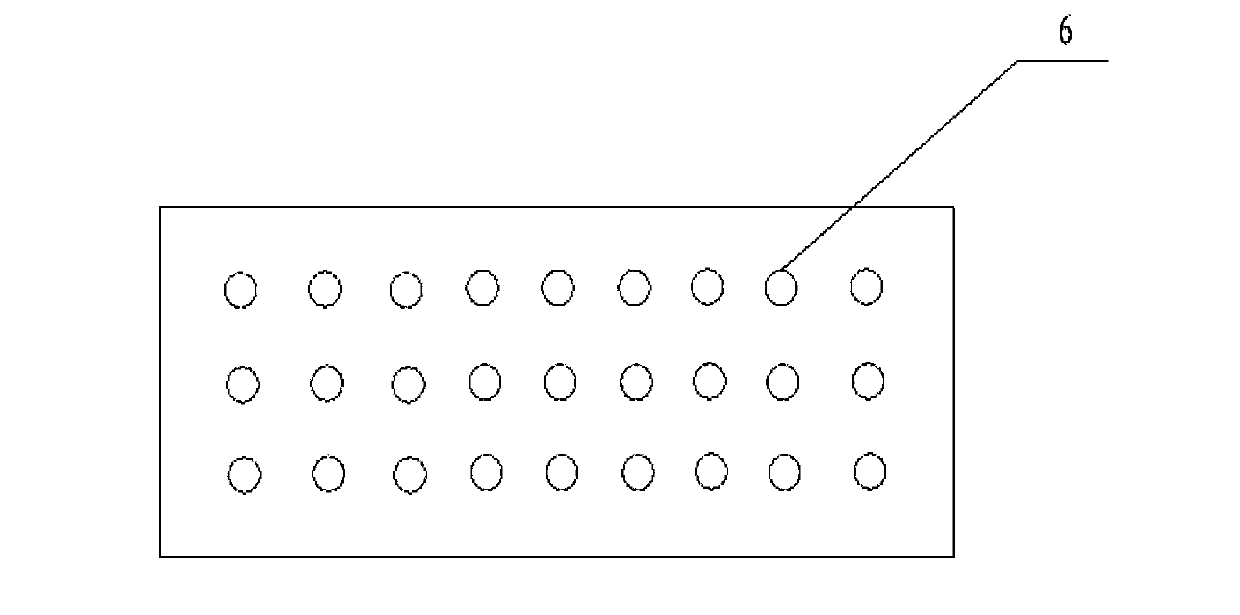

[0026] An arrangement of co-evaporation linear source arrays for copper indium gallium selenide thin film batteries, such as figure 1 , image 3 As shown, it includes a glass substrate 1 and linear evaporation sources 2, 3, and 4. The linear evaporation sources 2, 3, and 4 containing different raw materials are arranged longitudinally along the moving direction of the glass substrate 1 to form a linear evaporation source column. The linear evaporation source column is One column is located directly below the glass substrate 1 . The linear evaporation sources 2, 3, 4 are cylinders. The linear evaporation sources 2, 3, 4 are provided with an array of point-shaped evaporation holes 6, and the point-shaped evaporation holes 6 are divided into three rows along the running direction of the glass substrate. A row of dot-shaped evaporation holes 6 are respectively corresponding to the lower sides along the two sides of the glass substrate 1 . Three rows of dot-shaped evaporation ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com