A method with walnut shells as a cultivation of redzhi

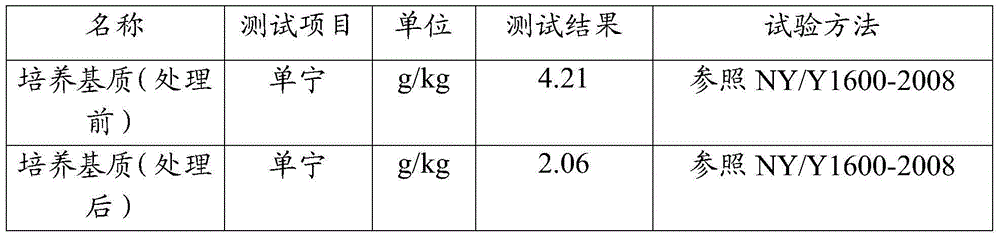

A technology for culturing substrates and walnut shells, applied in the field of Ganoderma lucidum cultivation, can solve problems such as unfavorable growth of Ganoderma lucidum mycelium, loss of nutrients, and achieve the effects of less loss of nutrients and reduction of hydrolyzed tannins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

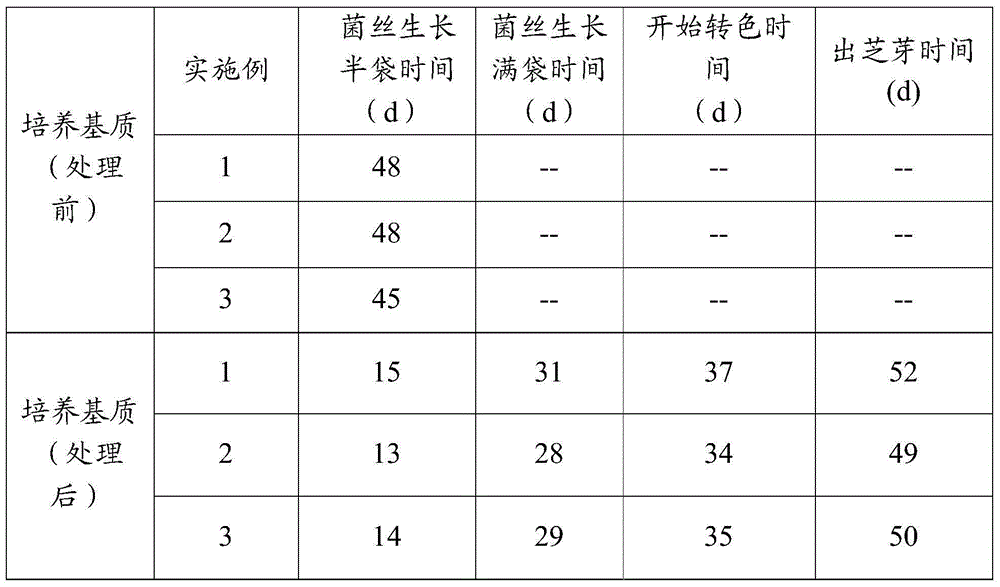

Examples

no. 1 example

[0023] A method for cultivating ganoderma lucidum with walnut shells as a culture substrate, comprising the steps of:

[0024] Step 1: Raw material pretreatment:

[0025] First walnut shells are crushed into particles with a diameter of 2mm;

[0026] Step 2: Preliminary hydrolysis of tannins:

[0027] Soak walnut shells in warm water at 35°C for 8 hours, the mass ratio of walnut shells to water is 1:3, remove the soaking liquid after soaking;

[0028] Step 3: Prepare soybean protein liquid:

[0029] Soak soybeans together with water, the ratio of soybeans to water is 1:4, soak continuously for 11 hours at 20°C, crush to make soybean milk;

[0030] Step 4: Semi-solid low-temperature fermentation:

[0031] Soybean milk and walnut shells soaked in water are fully stirred and combined to make them evenly mixed, and placed in an airtight environment at 10°C for 93 hours, wherein the mass ratio of soybean milk to walnut shells is 1:4;

[0032] Step Five: Drying:

[0033] The p...

no. 2 example

[0037] A method for cultivating ganoderma lucidum with walnut shells as a culture substrate, comprising the steps of:

[0038] Step 1: Raw material pretreatment:

[0039] First walnut shells are crushed into particles with a diameter of 3mm;

[0040] Step 2: Preliminary hydrolysis of tannins:

[0041] Soak walnut shells in warm water at 40°C for 9 hours, the mass ratio of walnut shells to water is 1:5, remove the soaking liquid after soaking;

[0042] Step 3: Prepare soybean protein liquid:

[0043] Soak soybeans together with water, the ratio of soybeans to water is 1:3, soak continuously for 10 hours at 25°C, crush to make soybean milk;

[0044] Step 4: Semi-solid low-temperature fermentation:

[0045] Soybean milk and walnut shells soaked in water are fully stirred and combined to make them evenly mixed, and placed in an airtight environment at 15°C for 96 hours, wherein the mass ratio of soybean milk to walnut shells is 1:3;

[0046] Step Five: Drying:

[0047] The p...

no. 3 example

[0051] A method for cultivating ganoderma lucidum with walnut shells as a culture substrate, comprising the steps of:

[0052] Step 1: Raw material pretreatment:

[0053] First walnut shells are crushed into particles with a diameter of 5mm;

[0054] Step 2: Preliminary hydrolysis of tannins:

[0055] Soak walnut shells in warm water at 45°C for 10 hours, the mass ratio of walnut shells to water is 1:7, remove the soaking liquid after soaking;

[0056] Step 3: Prepare soybean protein liquid:

[0057] Soak soybeans together with water, the ratio of soybeans to water is 1:3, soak continuously for 10 hours at 25°C, crush to make soybean milk;

[0058] Step 4: Semi-solid low-temperature fermentation:

[0059] Soybean milk and walnut shells soaked in water are fully stirred and combined to make them evenly mixed, and placed in an airtight environment at 13°C for 96 hours, wherein the mass ratio of soybean milk to walnut shells is 1:3;

[0060] Step Five: Drying:

[0061] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com