A kind of low-sugar lotus seed paste and its processing method

A technology of lotus seed paste and lotus seeds, which is applied in the direction of sugar-containing food ingredients, functions of food ingredients, food ingredients containing inorganic compounds, etc., can solve the problems of limiting the effect of lotus seeds, hard texture, intolerance to storage, etc., and achieve good taste and high utilization rate High, good antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

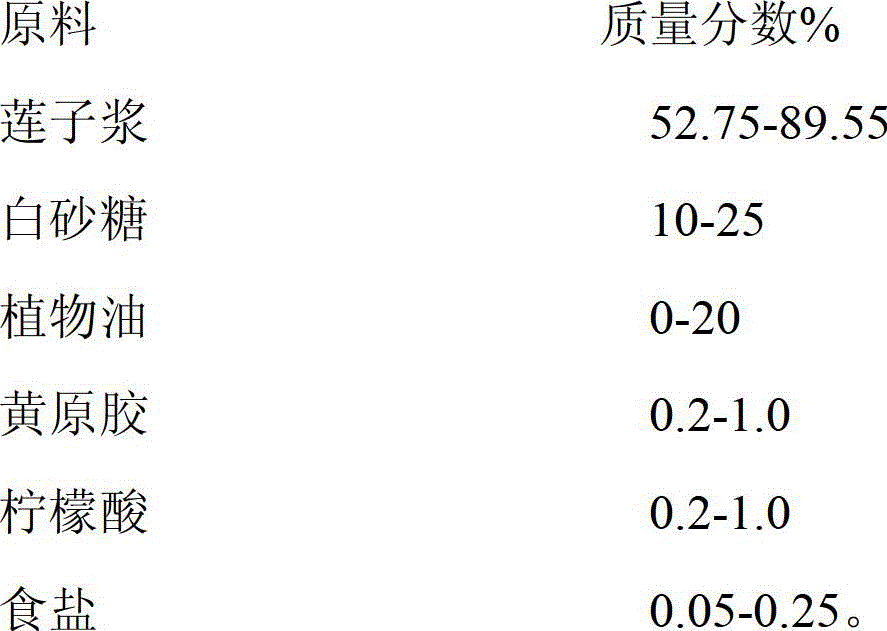

[0039] A kind of low-sugar lotus seed paste, it is made from the raw material of following weight portion:

[0040]

[0041] A kind of production method of low-sugar lotus seed paste, carries out according to the following steps:

[0042]1. Select the dried lotus seeds with normal color and no rot, remove the core, soak the lotus seeds in water with a mass ratio of 1:3~6 for 4 hours or 5 or 6 or 6 or 8 hours, and the water temperature is 20 or 22 or 24 or 25°C to make the lotus seeds Absorbs and softens. Heat the lotus seeds and the soaking liquid in a pressure cooker (at a temperature of 110°C or 114 or 116 or 118 or 120°C) for 20 minutes or 25 minutes or 28 minutes or 32 minutes or 36 minutes or 40 minutes to soften the lotus seeds and make them easy to beat. The lotus seeds are beaten with a high-speed tissue masher for 1min or 2min or 3min or 4min, then put into a colloid mill for colloid milling, and the emulsification fineness of the colloid mill is adjusted to 2 μm ...

Embodiment 2

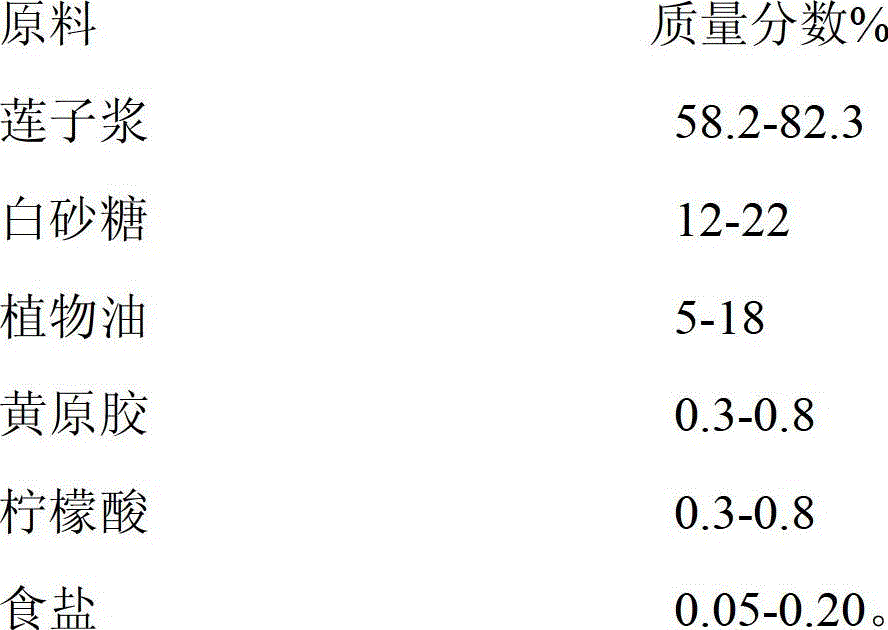

[0053] A kind of low-sugar lotus seed paste, it is made from the raw material of following weight portion:

[0054]

[0055] A kind of production method of low-sugar lotus seed paste, carries out according to the following steps:

[0056] 1. Select the dried lotus seeds with normal color and no rot, remove the core, soak the lotus seeds in water with a mass ratio of 1:3~6 for 4 hours or 5 or 6 or 6 or 8 hours, and the water temperature is 20 or 22 or 24 or 25°C to make the lotus seeds Absorbs and softens. Heat the lotus seeds and the soaking liquid in a pressure cooker (at a temperature of 110°C or 114 or 116 or 118 or 120°C) for 20 minutes or 25 minutes or 28 minutes or 32 minutes or 36 minutes or 40 minutes to soften the lotus seeds and make them easy to beat. The lotus seeds are beaten with a high-speed tissue masher for 1min or 2min or 3min or 4min, then put into a colloid mill for colloid milling, and the emulsification fineness of the colloid mill is adjusted to 2 μm...

Embodiment 3

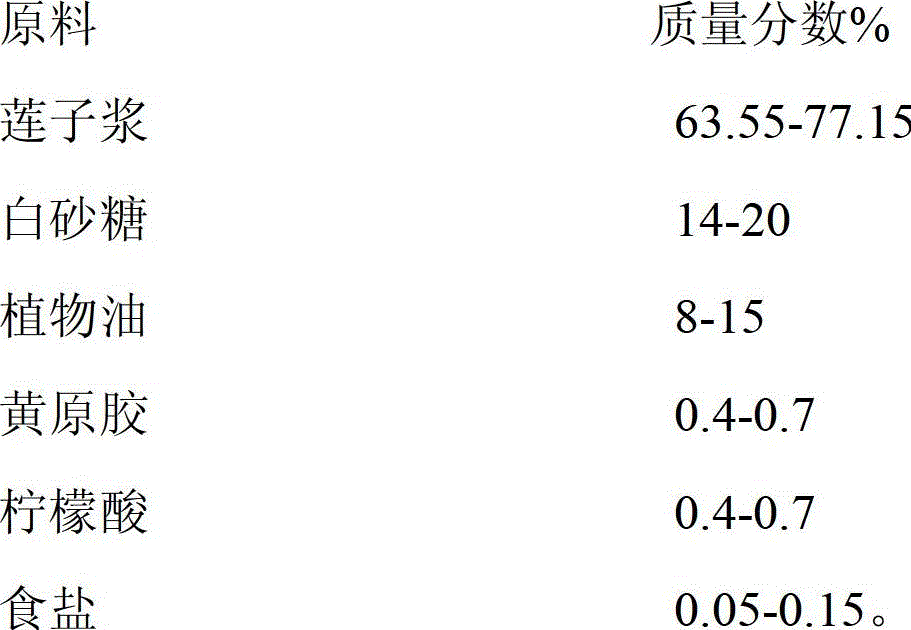

[0060] A kind of low-sugar lotus seed paste, it is made from the raw material of following weight portion:

[0061]

[0062] A kind of production method of low-sugar lotus seed paste, carries out according to the following steps:

[0063] 1. Select the dried lotus seeds with normal color and no rot, remove the core, soak the lotus seeds in water with a mass ratio of 1:3~6 for 4 hours or 5 or 6 or 6 or 8 hours, and the water temperature is 20 or 22 or 24 or 25°C to make the lotus seeds Absorbs and softens. Heat the lotus seeds and the soaking liquid in a pressure cooker (at a temperature of 110°C or 114 or 116 or 118 or 120°C) for 20 minutes or 25 minutes or 28 minutes or 32 minutes or 36 minutes or 40 minutes to soften the lotus seeds and make them easy to beat. The lotus seeds are beaten with a high-speed tissue masher for 1min or 2min or 3min or 4min, then put into a colloid mill for colloid milling, and the emulsification fineness of the colloid mill is adjusted to 2 μm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com