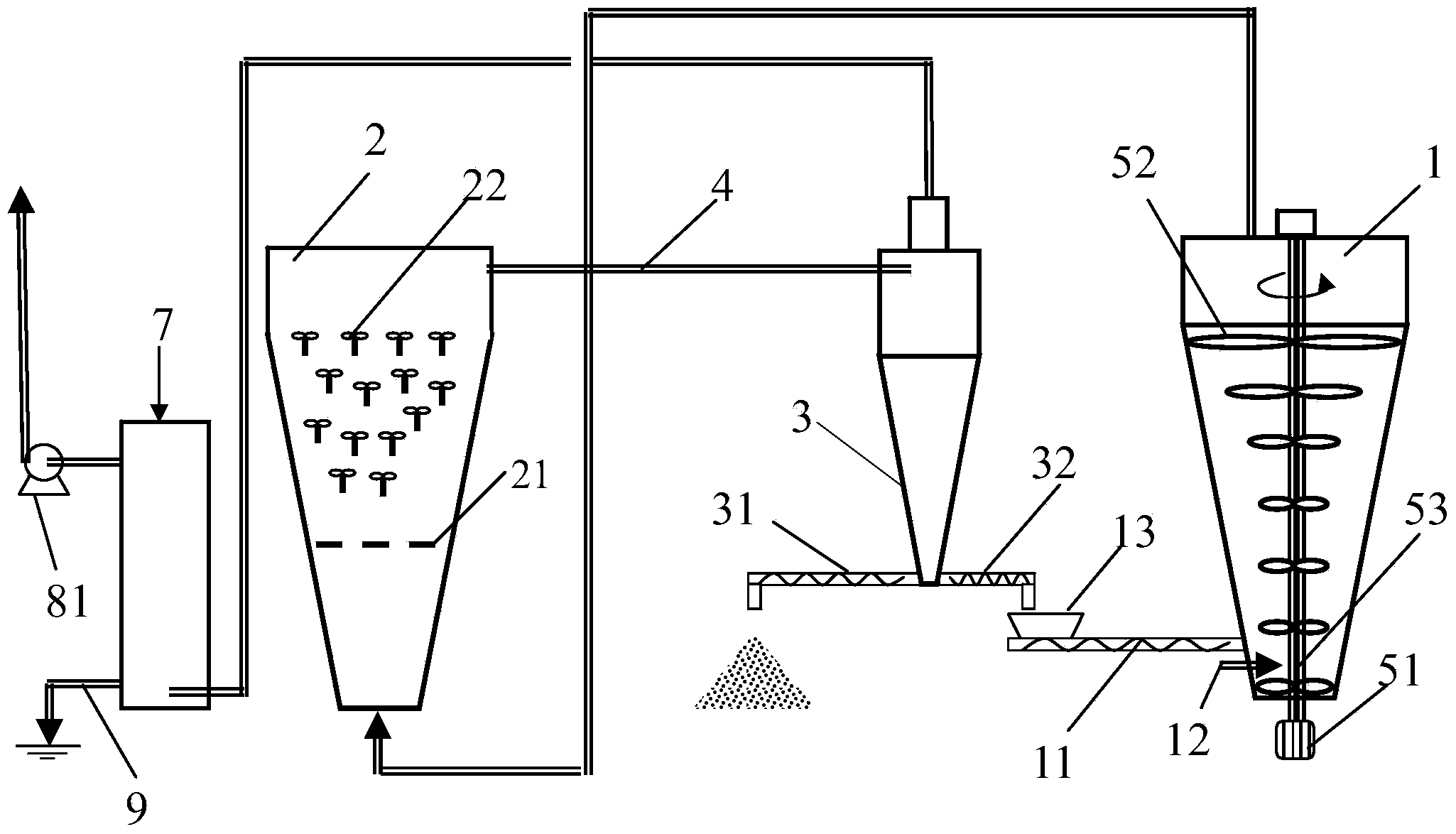

Circulating fluid bed air-drying system

A circulating fluidized bed and fluidized bed technology, applied in chemical instruments and methods, dehydration/drying/thickened sludge treatment, energy wastewater treatment, etc., can solve problems such as large weather influence, low efficiency, and increased sludge volume , to achieve the effect of high degree of automation, high drying efficiency and less equipment occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

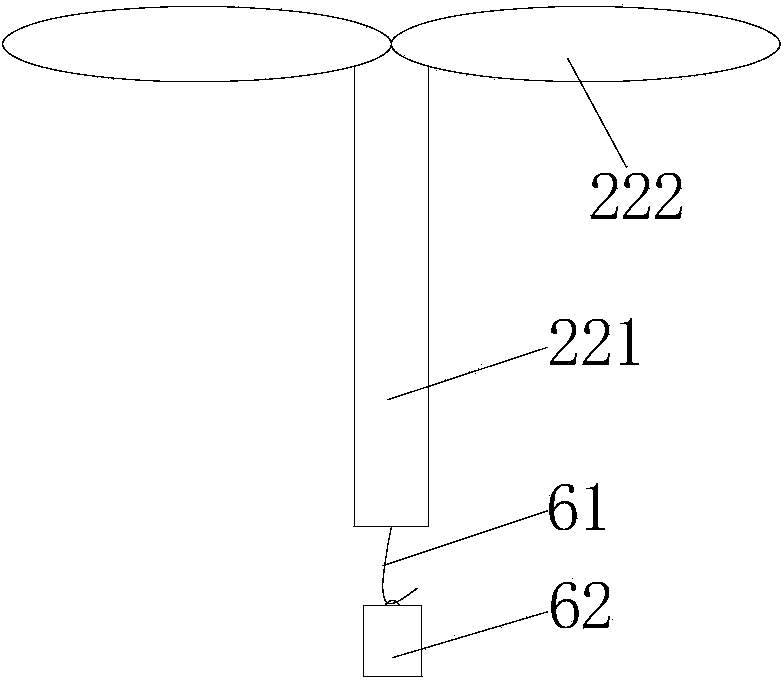

[0020] In the working process of a circulating fluidized bed air-drying system of the present invention, the fluidized bed air-drying tower 2 adopts the induced draft fan 81 connected to the upper end of the deodorizing device 7 to continuously draw air to form a negative pressure condition, and can work as usual in rainy weather. 32 By adjusting the circulation ratio to adapt to the granulation, fluidization and air-drying of materials with different moisture content and properties, the rotary crusher 1 adopts power rotary air-drying, on the one hand, it can ensure the wind speed, so that the material particles can fully contact with the air for mass transfer, on the other hand It can continuously break the particles, and those large-size particles will continue to settle down along the outer wall of the cone, and finally be crushed again by the crusher at the bottom, and then take off with the wind and join the rotating fluidized bed. The wind-driven rotary filler 22 can use ...

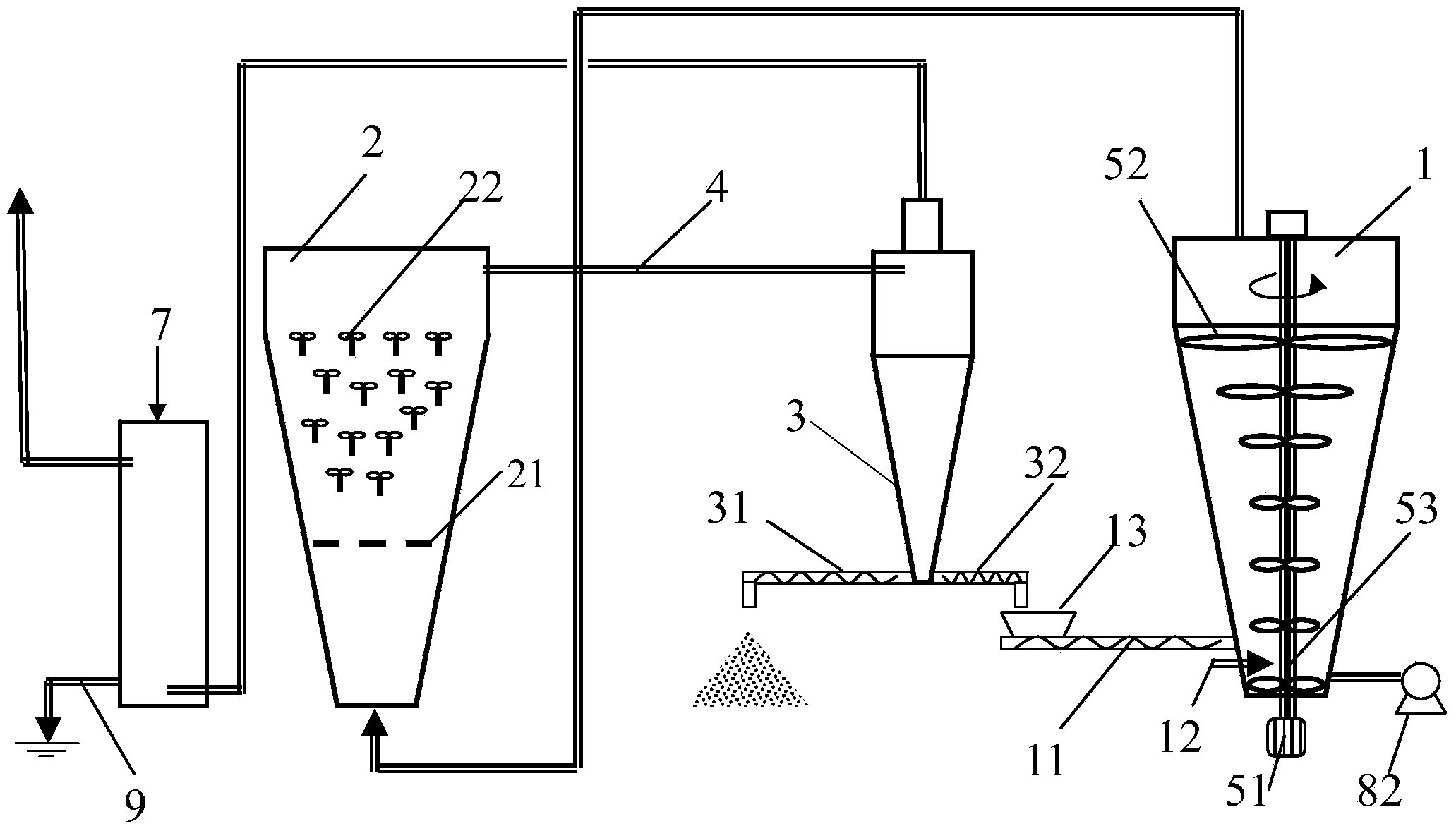

Embodiment 2

[0022] During the working process of a circulating fluidized bed air-drying system of the present invention, the fluidized bed air-drying tower 2 continuously blows air through the blower 82 connected to the bottom of the rotary crusher 1, and can work as usual in rainy weather. The circulating conveyor 32 adjusts the circulation ratio To adapt to the granulation, fluidization and air-drying of materials with different moisture content and properties, the rotary crusher 1 adopts power rotary air-drying. On the one hand, it can ensure the wind speed, so that the material particles can fully contact with the air for mass transfer, and on the other hand, it can continuously crush the particles. , those large-size particles continue to settle down along the outer wall of the cone, and finally are crushed again by the crusher at the bottom, and then take off with the wind and join the rotating fluidized bed. The wind-driven rotary filler 22 can use the wind speed to form a high-spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com