Preparation of modified nano barium sulfate and application of modified nano barium sulfate

A technology of nano-barium sulfate and nano-barium sulfate powder, which is applied in the direction of nanotechnology, nanotechnology, calcium/strontium/barium sulfate, etc., can solve the problems of difficult dispersion of nano-barium sulfate, easy yellowing, poor heat resistance, etc., and achieve Excellent heat resistance, low moisture content, and high whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

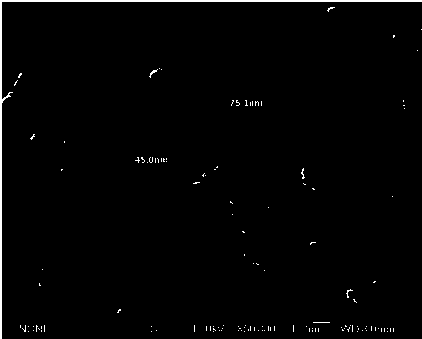

[0040] figure 1 Shown is the SEM picture of the modified nano barium sulfate that embodiment 1 makes, as seen from the figure, the product that makes is nanoscale, good dispersibility. The products obtained in Examples 1-4 are tested by a Malvern particle size tester, and it is found that the average particle diameter of the modified nano-barium sulfate powder prepared by this method is controlled between 45-120nm, and the maximum particle diameter Below 3 microns, it has the advantages of easy dispersion, excellent heat resistance, high whiteness, and low moisture content, and can be applied to the reinforcement and toughening of pipes, sheets, films, non-woven fabrics, fibers, and injection-molded plastic products. Masterbatch.

[0041] Agglomeration is easy to occur when the addition ratio of ordinary modified nano-barium sulfate exceeds 80%, white spots that cannot be dispersed are prone to occur in film products, and broken filaments are prone to occur in fibers and non-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com