Annealing method of cold-rolled non-oriented electrical steel thin strip

An annealing technology for oriented electrical steel, which is applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve problems such as annealing and smoothing process not mentioned in bell furnace, achieve excellent electromagnetic properties, expand application fields, and reduce broken belts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] 1. After normalization, cold rolling to 0.15mm, and the final pass of cold rolling is evenly sprayed with MgO aqueous solution;

[0013] 2. Roll bell annealing after cold rolling, using N 2 +H 2 Protection, N 2 Volume percentage: 30%; H 2 Volume percentage: 70%; heat preservation at 450°C for 5 hours, the purpose is to dry and cure the coating; annealing at 850°C for 12 hours, the purpose is to recrystallize and make the grain more uniform;

[0014] 3. Stretch annealing (concentration is 6% dilute H 2 SO 4 Wash off MgO), stress relief annealing at 650°C to make the best plate shape, tension 0.8KN;

Embodiment 2

[0016] 1. After normalization, it is cold rolled to 0.18mm, and the final pass of cold rolling is uniformly sprayed with MgO aqueous solution;

[0017] 2. Roll bell annealing after cold rolling, using N 2 +H 2 Protection, N 2 Volume percentage: 20%; H 2 Volume percentage: 80%; heat preservation at 420 ° C for 3 hours, the purpose of drying and curing the coating; annealing at 880 ° C for 12 hours, the purpose of recrystallization and more uniform grains;

[0018] 3. Stretch annealing (concentration is 6% dilute H 2 SO 4 Wash off MgO), stress relief annealing at 750°C to make the best plate shape, tension 1.2KN;

Embodiment 3

[0020] 1. After normalization, cold rolling to 0.20mm, and the final pass of cold rolling is evenly sprayed with MgO aqueous solution;

[0021] 2. Roll bell annealing after cold rolling, using N 2 +H 2 Protection, N 2 Volume percentage: 40%; H 2 Volume percentage: 60%; heat preservation at 480°C for 7 hours, for drying and curing the coating; annealing at 920°C for 12 hours, for recrystallization and more uniform grains;

[0022] 3. Stretch annealing (concentration is 6% dilute H 2 SO 4 Wash off MgO), stress relief annealing at 850°C to make the best plate shape, tension 1.5KN;

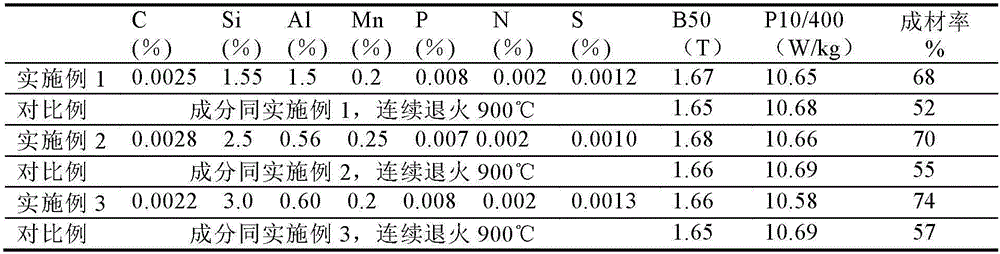

[0023] The cold-rolled non-oriented electrical steel thin strip obtained according to the above-mentioned process has no oxidation on the surface of the steel plate, flat shape, and the same plate difference is ≤ 10 μm. The electromagnetic properties are as follows:

[0024]

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com