Production method of anti-fake gas bottle collar

A production method and collar technology, which are applied to record carriers, instruments, and computer parts used in machines to improve reliability, eliminate hidden safety hazards, and are not easy to fall off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

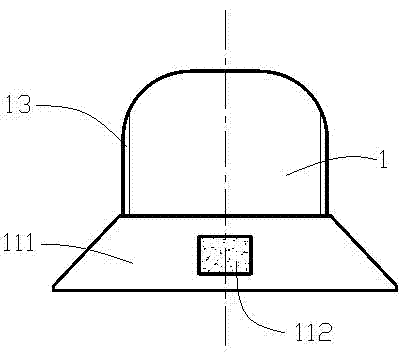

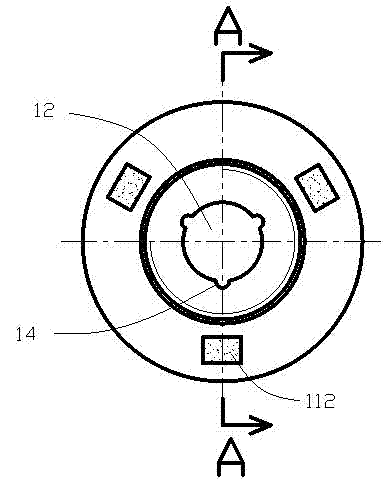

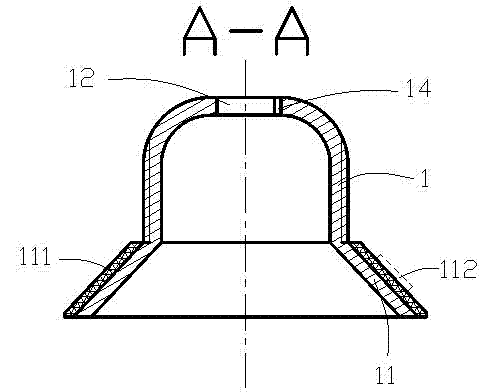

[0048] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below through specific embodiments and related drawings.

[0049] A method for producing an anti-counterfeit gas bottle neck ring of the present invention comprises the following steps:

[0050] Step S01: stamping and stretching the steel plate, and performing pretreatments of degreasing, derusting, neutralizing and drying;

[0051] Step S02: Grinding the prepared enamel ingredients into a glaze slurry, the raw material formula of the enamel includes the following components in parts by weight:

[0052] Italian glass glaze: 50~60 parts;

[0053] Quartz sand: 10~15 parts;

[0054] Kaolin: 3~6 parts;

[0055] Anti-fish scale explosion additive 0.8~1.5 parts;

[0056] Sodium nitrite 0.4~0.5 parts;

[0057] Oxidizing agent 0.4~0.5 parts;

[0058] 35~45 parts of water.

[0059] (The raw material formula of the ename...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com