Oxygen reduction device and refrigerator

A technology for oxygen reduction devices and refrigerators, which can be used in household refrigeration devices, lighting and heating equipment, applications, etc., and can solve problems such as low durability of oxygen reduction devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

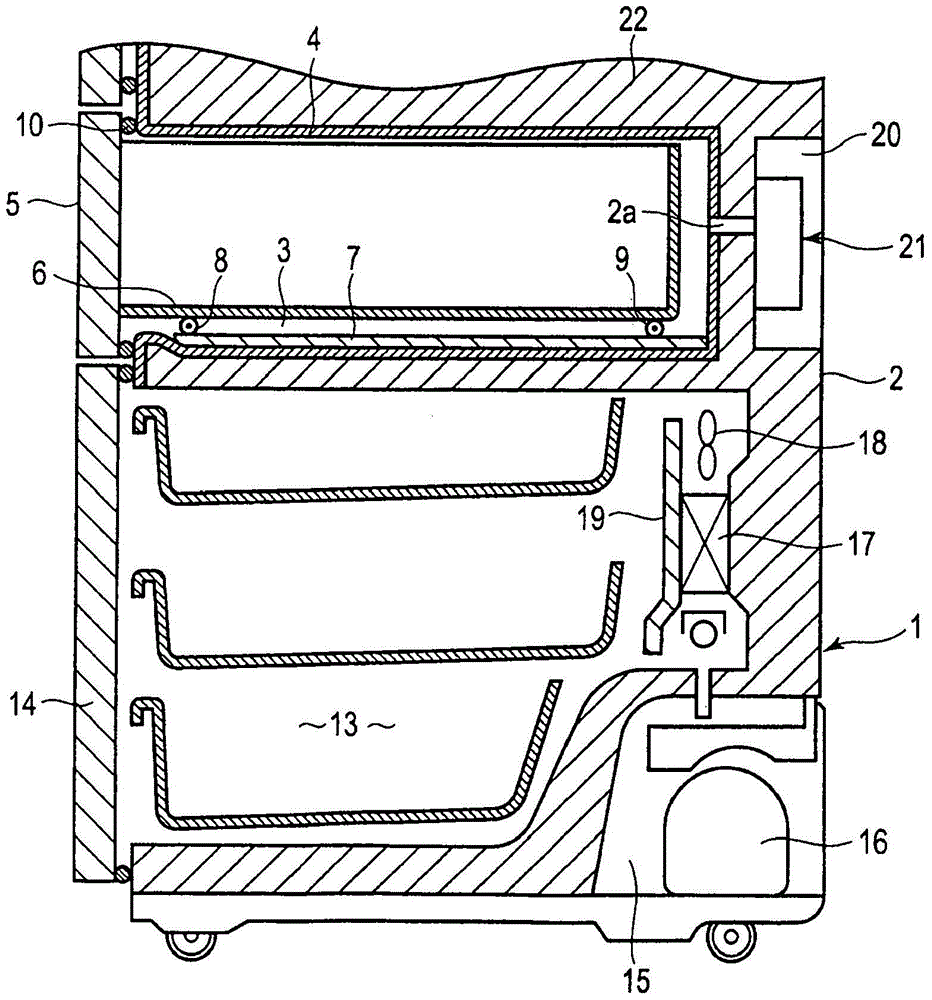

Embodiment 1)

[0150] In Example 1, the vaporized layer 38 was obtained by the following manufacturing method. First, carbon paper having a thickness of 180 μm was immersed in a PTFE dispersion solution for 1 minute, and then dried overnight at room temperature. Next, the thus-dried carbon paper was fired at 380° C. for 10 minutes in an argon atmosphere. Thereby, vaporized layer 38 including carbon paper with a content of 5 wt% of PTFE as a fluororesin was obtained. The vaporized layer 38 was evaluated by pore distribution measurement. As a result, the vaporized layer 38 had a median diameter of 35 μm and a porosity of 70%.

Embodiment 1

[0152] Evaluations in Example 1 are as follows.

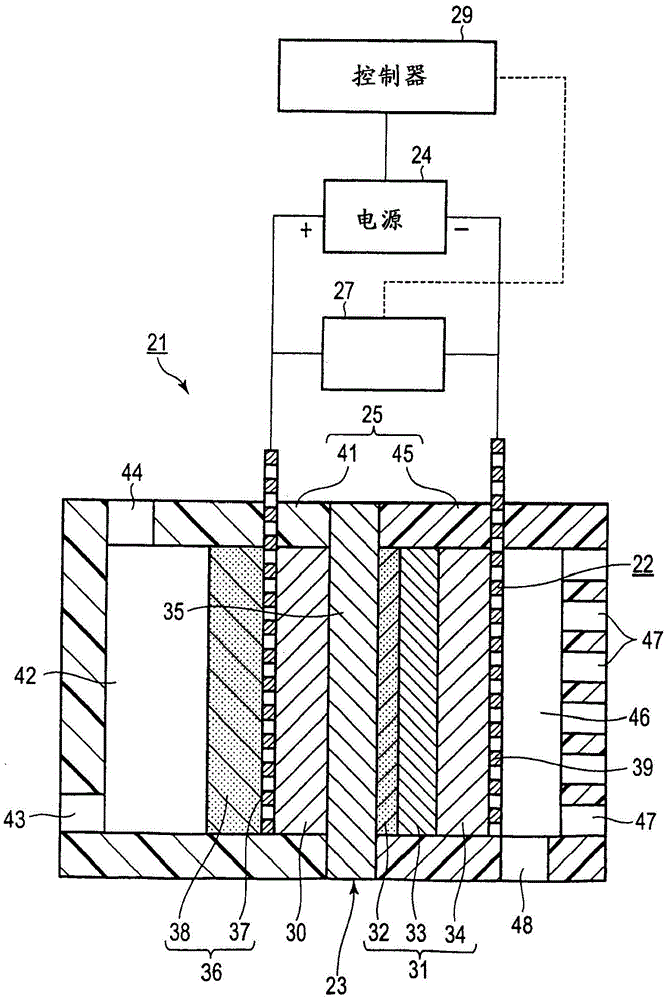

[0153] The oxygen reduction stack 22 is interposed between the first container member 41 and the second container member 45 , and these are connected to form the oxygen reduction container 25 . Thus, the oxygen reduction device 21 is produced. The anode collector layer 37 and the cathode collector layer 39 of this device were connected to the power source 24 . In the evaluation of the oxygen reducing device 21, the anode chamber 42 of the first container part 41 containing the anode 30 is filled with water (liquid), and air is supplied to the cathode chamber 46 of the second container part 45 containing the cathode 31 by active breathing. .

[0154]In such a state, a voltage is applied from the power source 24 to the oxygen reduction unit 23 and controlled so that the reaction current becomes a constant current. This constant current control is performed by, for example, a voltmeter 27 (refer to figure 2 ) to detect the vo...

Embodiment 2)

[0156] In the same manner as in Example 1, a gasification layer 38 made of carbon paper having a thickness of 180 μm and a PTFE content of 10 wt % was produced and obtained. The gasification layer 38 was evaluated by pore distribution measurement, and the gasification layer 38 had a median diameter of 35 μm and a porosity of 65%. The same operation as in Example 1 was carried out to fabricate an oxygen reduction device having the gasification layer 38, and the oxygen reduction reaction was performed by the same operation as in Example 1, and the electrolysis voltage was measured 1 hour and 1000 hours after the start of the reaction. The results are shown in Tables 1 to 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com