Carbon deposit processing device and method of air cylinder and accelerants

A carbon deposition treatment and catalyst technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as catalysts, carbon deposition, and slow down the formation of carbon deposition, so as to eliminate carbon deposition and prolong life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

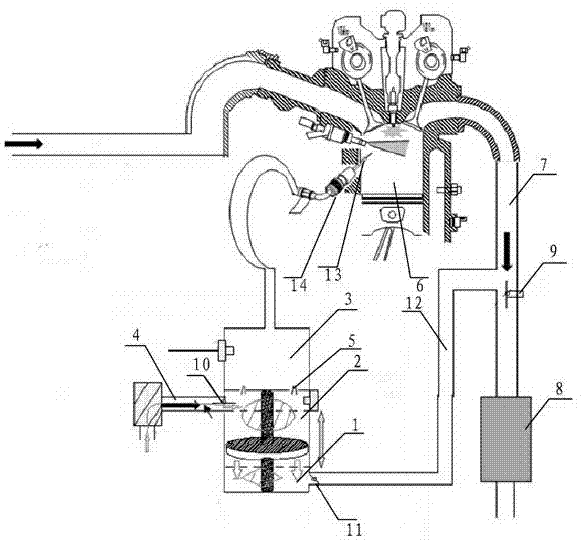

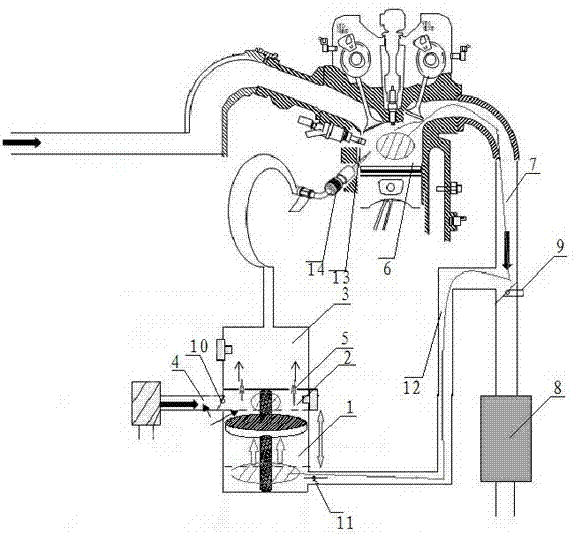

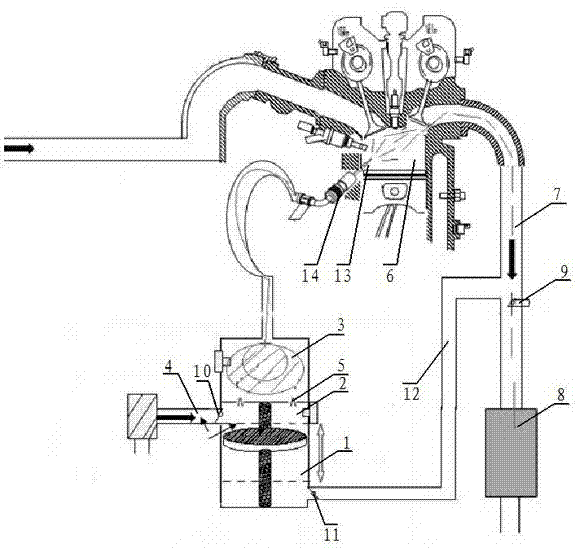

[0037] Embodiment one: see Figure 1 to Figure 3 Shown, a kind of carbon deposit treatment device of cylinder and catalyst, comprises:

[0038] A compressed air generating mechanism, the compressed air generating mechanism has a piston chamber and a compressed air storage chamber, the piston chamber is separated by a built-in piston to form a first chamber and a second chamber, and the second chamber is provided with air Inlet, the second chamber is one-way connected to the compressed air storage chamber through a one-way valve;

[0039] The first valve body, the first valve body is arranged on the exhaust pipe, between the combustion chamber and the catalyst, the first chamber communicates with the exhaust pipe through the connecting pipe, and the connection point between the connecting pipe and the exhaust pipe is located at Between the combustion chamber and the first valve body;

[0040] A second valve body, the second valve body controls the on-off of the air inlet on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com