Sawtooth bellow expansion joint

A technology of bellows and expansion joints, which is applied in the field of expansion joints for vertical pipelines, can solve the problems of corroded damage at the bottom of corrugated grooves, penetrating damage of bellows, corrosiveness of bellows, etc., and achieves easy manufacturing and improved The effect of improving service life and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

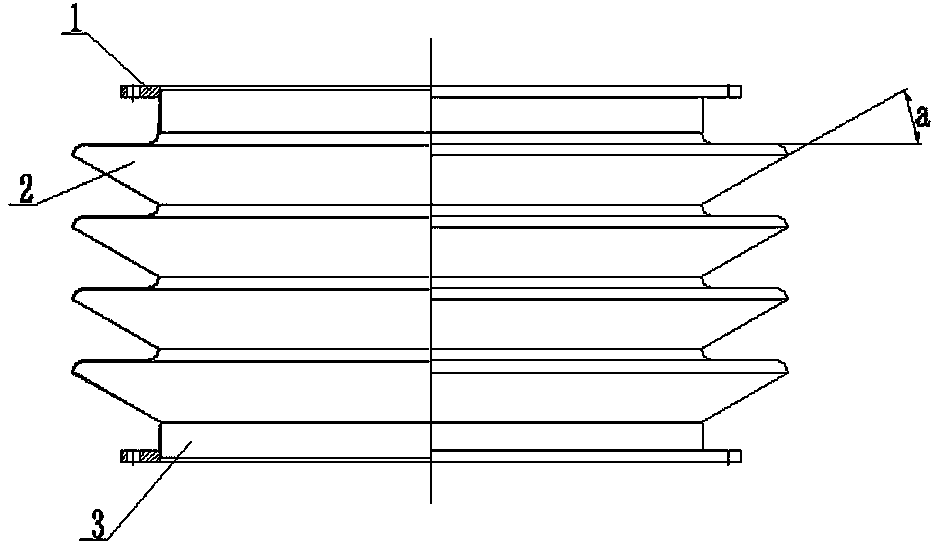

[0017] figure 1 The zigzag bellows expansion joint shown is a vertical structure. In this embodiment, it is installed in the exhaust gas pipeline of the carbon black industry, and its caliber is DN=1600mm. The expansion joint is composed of a flange 1 , a bellows 2 and a connecting pipe 3 . The flange 1 is an external connecting piece of the expansion joint, the flange 1 located at the upper and lower ends seals the connecting pipe 3, and the two ends of the bellows 2 are respectively butted with the corresponding connecting pipe 3. In order to avoid the residual medium at the bottom of the concave groove of the corrugated pipe 2, the present invention designs the toothed wave of the corrugated pipe 2 as a zigzag shape. The toothed wave of this embodiment is a triangle with a single hypotenuse facing downwards. The included angle of the wave is α=30 0 , the flat side of the tooth-shaped wave is located at the upper part, and the lower side is the hypotenuse. The two tooth-sh...

Embodiment 2

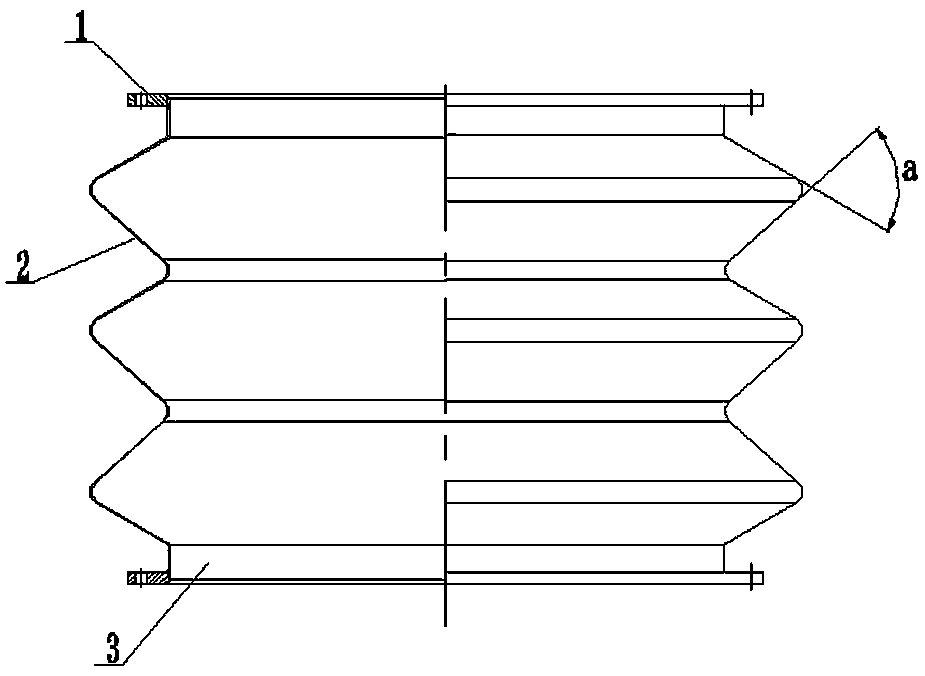

[0019] figure 2 The sawtooth bellows expansion joint shown has the same structure as that of Embodiment 1, and it is matched in the pipeline at the outlet of the air preheater in the carbon black industry. The caliber of this embodiment is DN=500mm. Because the caliber is smaller than that of Embodiment 1, the transmission medium contains a large amount of carbon black particles. The tooth-shaped wave is an isosceles triangle, and the included angle of each tooth-shaped wave is α=60 0 , the upper and lower sides are 30 0 Inclined, an arc connection is used between the two toothed waves. The application effect of the bellows 2 with this structure is similar to that of the embodiment 1, so no further description is given.

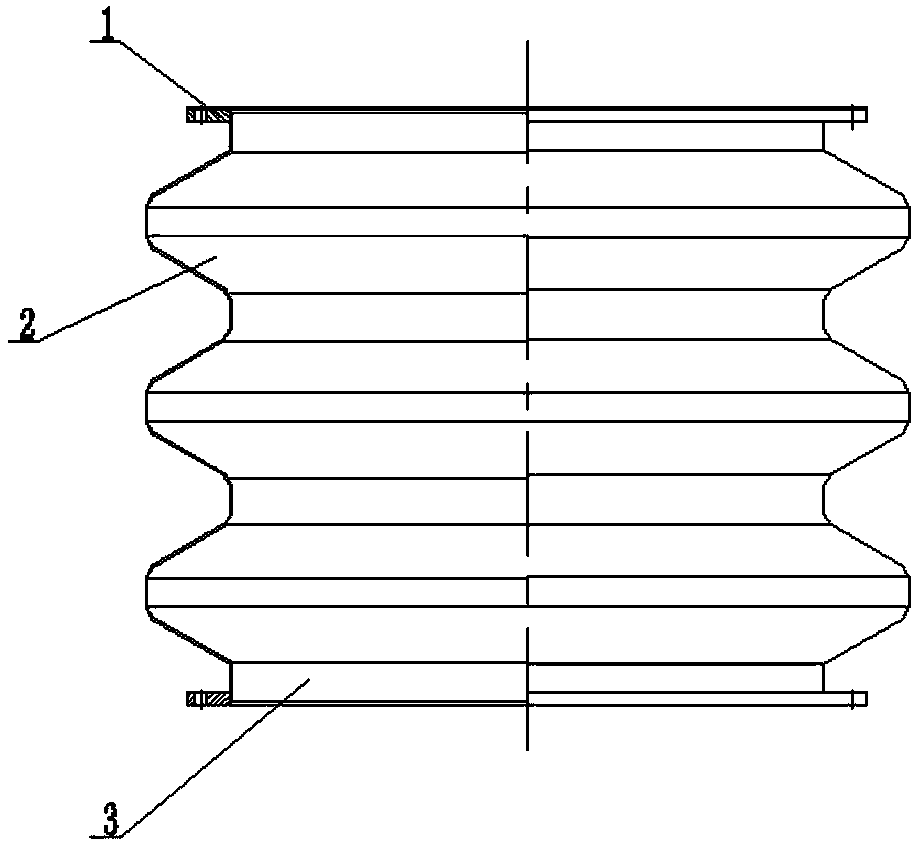

[0020] Embodiment 1 and embodiment 2 are only typical examples of the present invention, and cannot represent all technical solutions of the present invention. For example, the toothed wave of bellows 2 is image 3 The trapezoid shown is also a similar s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com